On/off tuning has no provision

for fluctuating loads. Blindly responds

only to on-to-off point and off-to-on

point. Change in load may change

oscillation amplitude and/or period.

STEPS:

1. For on/off control, enter program

mode, navigate to "CYC.t"

function on level 1. Set "on.of".

Have to go down to "0" to get to

"on.oF"

2. Then set dead band width. Index

down to "bAnd" function and set

distance between on-to-off point

and off-to-on point.

PROPORTIONAL CON-

TROL

Proportional control eliminates

oscillation. It controls steady-state

by weakening power as oxygen level

approaches setpoint. When power

(gas infused per unit time) exactly

matches load (gas leaking out per

unit time), oxygen stabilizes.

Unlike ON/OFF control where

power is either 100% or 0%, propor-

tional control can adjust power any-

where between 100% and 0%. Power

is adjusted by timing gas pulses.

"Proportional" means gas pulses get

proportionately smaller as the dis-

tance between oxygen level and

setpoint (SP1) gets smaller.

Pulses are timed by setting a

cycle time and varied by percentage

of the cycle time. Maximum pulses

are 100% of cycle time. Minimum

pulses are 0% of cycle time. Propor-

tioned pulses are in between.

Timed pulse proportioning oc-

curs only over a narrow band of oxy-

gen levels centered around set point.

Control gas is infused full blast (100%

output) with no timing until it reaches

this band. Then it cycles. The

deeper it goes into the proportional

band, the shorter the pulses. Band

size determines how quick pulses

shorten and power thus weakens.

Somewhere between 100%

and 0% of the cycle time there's a

pulse time that holds steady state.

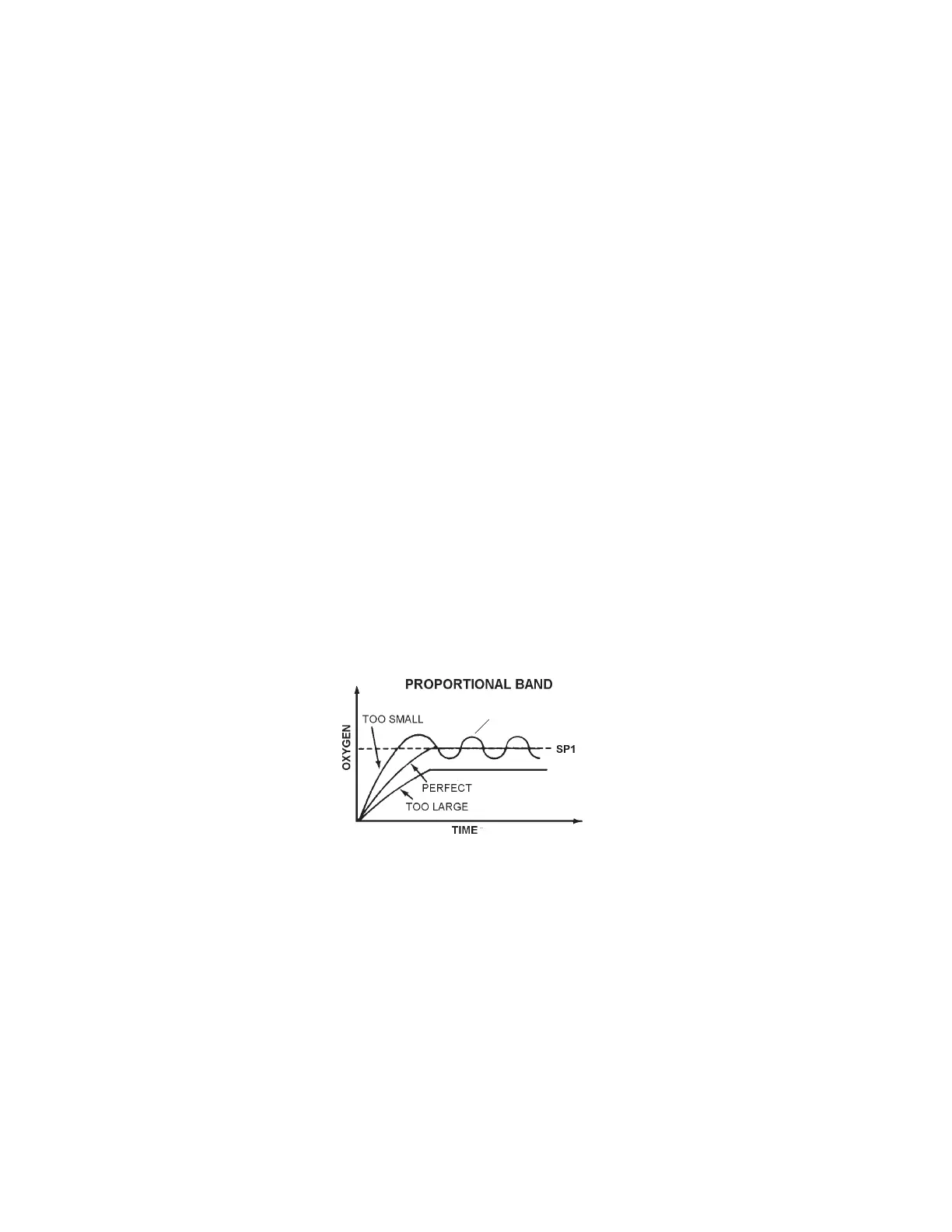

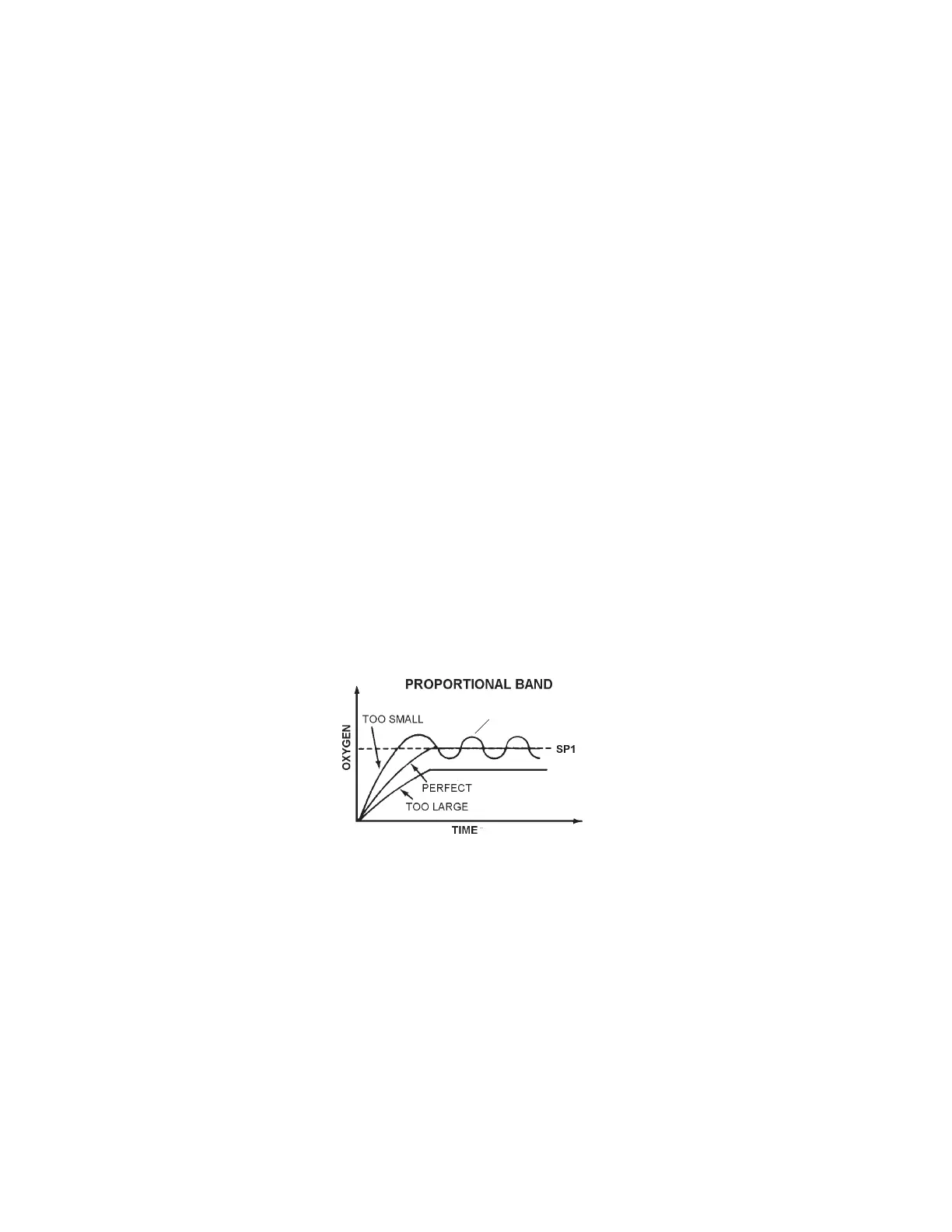

However, if proportional band is too

small, it may not be easy to find.

Small changes in oxygen will cause

huge changes in output, similar to

ON/OFF control. Oxygen will oscil-

late and never reach steady state.

On the other hand, if propor-

tional band is too wide, proportioning

inhibits approach to setpoint. Power

starts decreasing way to soon.

Proportional band should be

big enough so there's no gross over-

shoot everytime proportioning kicks

in, but not so big that there's need-

less pulsing long before oxygen gets

even close to setpoint.

Cycle time should be as long

as possible to minimize wear and

tear on equipment, but not so long

that it becomes unresponsive.

If no other control parameters

are set, proportional band centers

around setpoint SP1. All additional

parameters accentuate proportional

control. Without proportional control

( prop. band and cycle time), no other

parameters are active. Some affect

the position of the band, but not the

size. Some affect the size, but not

the position. None affect the cycle

time.

STEPS:

1. To tune proportional control, enter

program mode, navigate to

"CYC.t" function on level 1. Set

cycle time, anywhere from 0.1 -

81 seconds.

2. Then index down to "bAnd"

function and set proportional

band. Gas power is reduced, by

time proportioning action, across

this band centered around SP1.

3. Exit program mode to work mode

and watch control process. Note

whether process overshoots and

oscillates, or undershoots from

cycling long before reaching

setpoint.

4. Enter program mode, and

navigate to "bAnd" function

again. If process overshot and

oscillated, increase band size. If

process undershot and took long

to reach setpoint, decrease band

size.

5. Repeat steps 3-4 till steady state

is achieved, whether steady state

is at setpoint or not.

MANUAL OFFSET

Proportional band is basically

a "blind" control parameter. When

set alone, it positions itself arbitrarilly,

centered around the setpoint.

Chances are steady-state will not be

at setpoint.

If proportional control steady-

state is not at setpoint, the offset

must be eliminated to move steady-

state to setpoint.

Manual Offset moves propor-

tional band by a fixed distance so

that steady-state is at setpoint. If

steady-state is +0.3% oxygen above

setpoint, then an offset of -0.3 will

move proportional band down so

pulse is perfectly proportioned to

match load at setpoint.

Manual offset works good when

controlling against a fixed load. Once

set, it makes proportional control

nearly perfect. No overshoot either.

STEPS:

1. Watch control process in work

mode till steady state is reached.

Note the variance from setpoint.

2. Enter program mode, navigate to

"oFSt" function on level 1, and

set number that offsets variance.

NOTE: "int.t" function on level 1

must be set to "oFF" to manually

adjust offset, otherwise "oFSt"

function is not active but read-

only.

INTEGRAL CONTROL

AUTOMATIC OFFSET

RESET

Proportional control jobs with

fluctuating loads, require automatic

offset to keep steady state at

setpoint.

Integral control parameter au-

tomatically and continuously moni-

tors divergences between setpoint

and steady state, and acts to correct

offset by repositioning proportional

band. Changes the area between set

point line and oxygen level line, and

shifts proportional band in proper

direction to minimize area. As load

changes, steady state follows

setpoint if integral is tuned properly.

Integral control overshoots on

initial start up and after significant

interruptions. Far away from setpoint

it senses big offset, so it shoots

proportional band as far as possible

in corrective direction. Only after

passing setpoint does integral pick

up the need to bring proportional

band back to near setpoint.

Integral control parameter is

time. Resets offset as frequently as

you specify. If integral time is too

short, it recalculates too many times

before oxygen moves much and

moves proportional band too far too

fast. Result is oscillation. Eventu-

Oscillation

16

Proox model 360

version 1.0

Loading...

Loading...