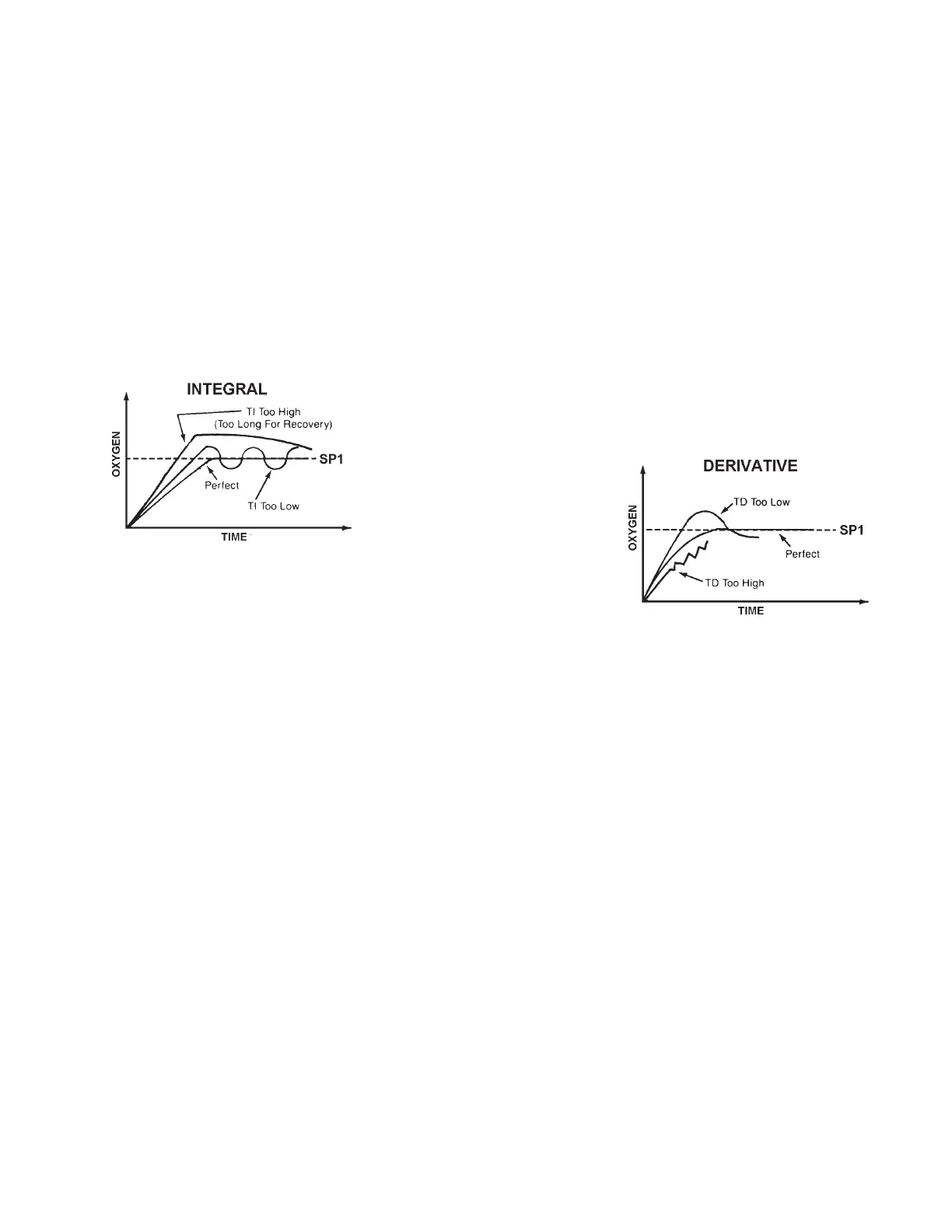

ally oscillation will dampen to steady

state, if load hasn't changed yet.

If integral time is too long, it's

slow to respond. Steady state and

setpoint take a long time to merge.

STEPS:

1. Watch oxygen control process in

work mode under normal load

change. Note offset at one load.

While load changes, note time till

new offset stabilizes at steady

state. To change load open the

chamber door and ventilate.

2. Enter program mode, navigate to

"int.t" function on level 1, and

set integral time to 30-70% of

noted time. Range is 0.1 - 60

minutes.

3. Exit program mode to work mode.

Watch as normal load changes

occur, and note time till offsets

disappear.

4. Repeat steps 2 and 3 until control

is acceptable.

DERIVATIVE CONTROL

The most demanding control

job is the one that has to be fast and

tight under fluctuating loads. With

power and proportional band tuned

aggressively (high power, narrow

band), conditions are ripe for over-

shoot. Add integral action and over-

shoot is virtually guaranteed, at

startup and after large disturbances.

Derivative control suppresses

overshoot. It also speeds response

to disturbances, large or small.

Derivative algorithms measure

rate and direction of change of oxy-

gen in relation to setpoint. Then

temporarily, but quickly shifts pro-

portional band in opposite direction,

by a distance proportional to the rate

of change. The faster the change,

the further it shifts. Shift is just long

enough to "extract" an output deter-

mination.

The effect is to quickly weaken

power on approach to setpoint, and

quickly boost power if oxygen sud-

denly pulls away from setpoint. Prop-

erly tuned, derivative should not dis-

turb proportional or integral action at

steady state.

On fast approach to setpoint

without derivative, when oxygen first

hits proportional band the initial pulse

might be 97% of cycle time. That's

not very weak. The next pulse might

be significantly less, but by that time

it's too late. Oxygen changed too

fast. Overshoot already occurred.

When integral action finally kicks in,

it's way too late.

With derivative, fast oxygen

change immediately pulls up propor-

tional band. Then first pulse might be

1% of cycle time. This quickly slows

approach to setpoint. Slower rate of

change calculation might only "ex-

tract" a pulse of 12% of cycle time.

Slower still, maybe 19%.

As rate of change of oxygen

decreases, derivative action de-

creases. At steady state there's no

derivative action. Ideally at that point

oxygen is near setpoint and integral

action takes over.

Derivative also speeds re-

sponse to disturbances. Without it,

as oxygen quickly diverges away

from setpoint, the first pulse from

proportional control band might be

only 22% of cycle time, the second

pulse 53%, the third 87%, and by the

time output goes to 100%, oxygen is

far away.

With derivative, the fast change

in oxygen away from setpoint would

immediately pull proportional band

back toward setpoint and result in

100% output before oxygen gets too

far.

Derivative control is hardest to

tune. Proper setting is very sensitive

to gas dynamics and other control

parameters. If it is not required, keep

it off as it will tend to reduce control

stability.

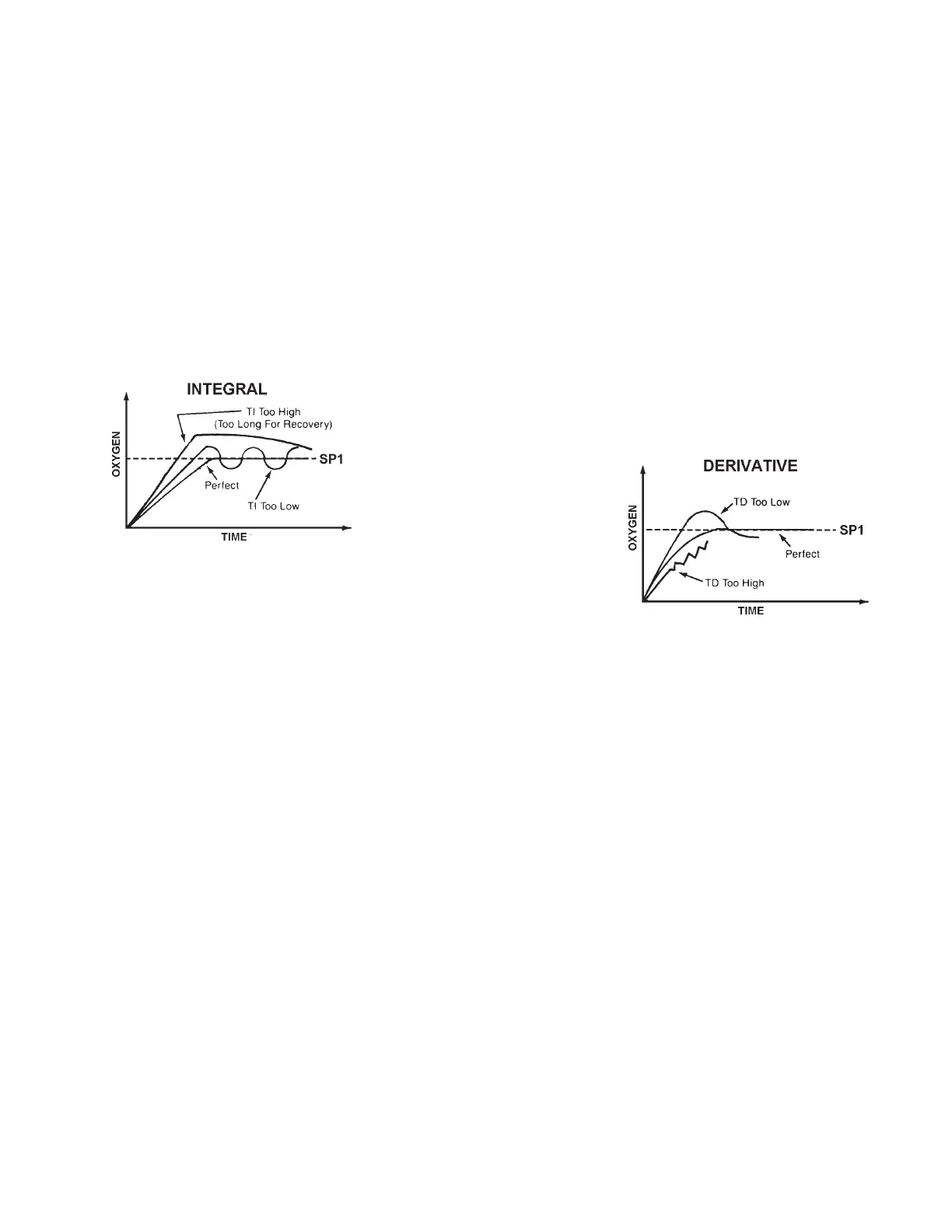

Derivative parameter is time.

Sets rate of corrective action. Rule-

of-thumb: set 3-8 times faster than

integral. If too short it inhibits reach-

ing setpoint and slows response to

upsets. If too long, it oscillates and

overcorrects. Is only active in pro-

portional band.

STEPS:

1. With power, proportional, and

integral parameters set, watch

control process in work mode.

Note overshoot. Next open

chamber briefly to induce large

upset in control. Note speed of

response.

2. Enter program mode, navigate to

"dEr.t" function on level 1,and

set derivative time. Range 0.1 -

0.4 of integral time.

3. Exit program mode, air out

chamber, watch control process

and note overshoot on approach

and response to disturbance.

4. Re-enter program mode, and

navigate to "dEr.t" function

again. If too much overshoot on

approach and too slow response

to upset, decrease derivative

time. If approach to setpoint is

inhibited and response under

corrects, increase derivative

time.

5. Repeat steps 3-4 until overshoot

on approach and response to

upset is acceptable.

17

Proox model 360

version 1.0

Loading...

Loading...