Tuning

Tuning matches control parameters of Proox 360 to gas dynamics of

host chamber to achieve effective control.

TUNING

Different oxygen control jobs in

different chambers require specific

control parameters. Tuning means

setting those control parameters that

result in acceptable control.

Which parameters to set, and

how to set them, depends on the job.

Is oscillation acceptable? If so how

much? Is overshoot permissable?

Undershoot? How much? For how

long? Is the load fixed or variable?

Does setpoint change? Must recov-

ery be fast?

Capability exists to handle prac-

tically any oxygen control job. How-

ever, the more complex and demand-

ing the job, the more involved tuning

becomes.

Tune only what's necessary to

accomplish the job. Any additional

control parameters probably won't

help, and might hurt. Excessive tun-

ing can reduce control stability.

Most oxygen control jobs are

simple. Thus tuning is easy. Only a

few parameters need to be set. Ad-

vanced control capabilities are avail-

able, but use them only if you need to.

Just watch the control process

and see how each control parameter

affects it. This is the only definitive

way. Usually it's the easiest too.

Tuning takes time. It takes gas.

It means sitting and watching the

control process, sometimes over and

over. There is no shortcut. Trial and

error is the only way to tell if a tune set

works. Along with the Proox 360 you

are provided with a "Control Param-

eters Chart", this chart has all the

pretuning information that was done

at the factory. Don't lose this chart,

but if you do then call the number at

the front of this manual to receive a

new copy.

Always change only one control

parameter at a time. See how that

setting works first, before changing

another. Record each tune set. When

satisfied with control, copy and set

aside for safekeeping.

A tune doesn't have to be per-

fect to work. But don't stop short

either. Once tuning is done and done

right, it may never need further at-

tention.

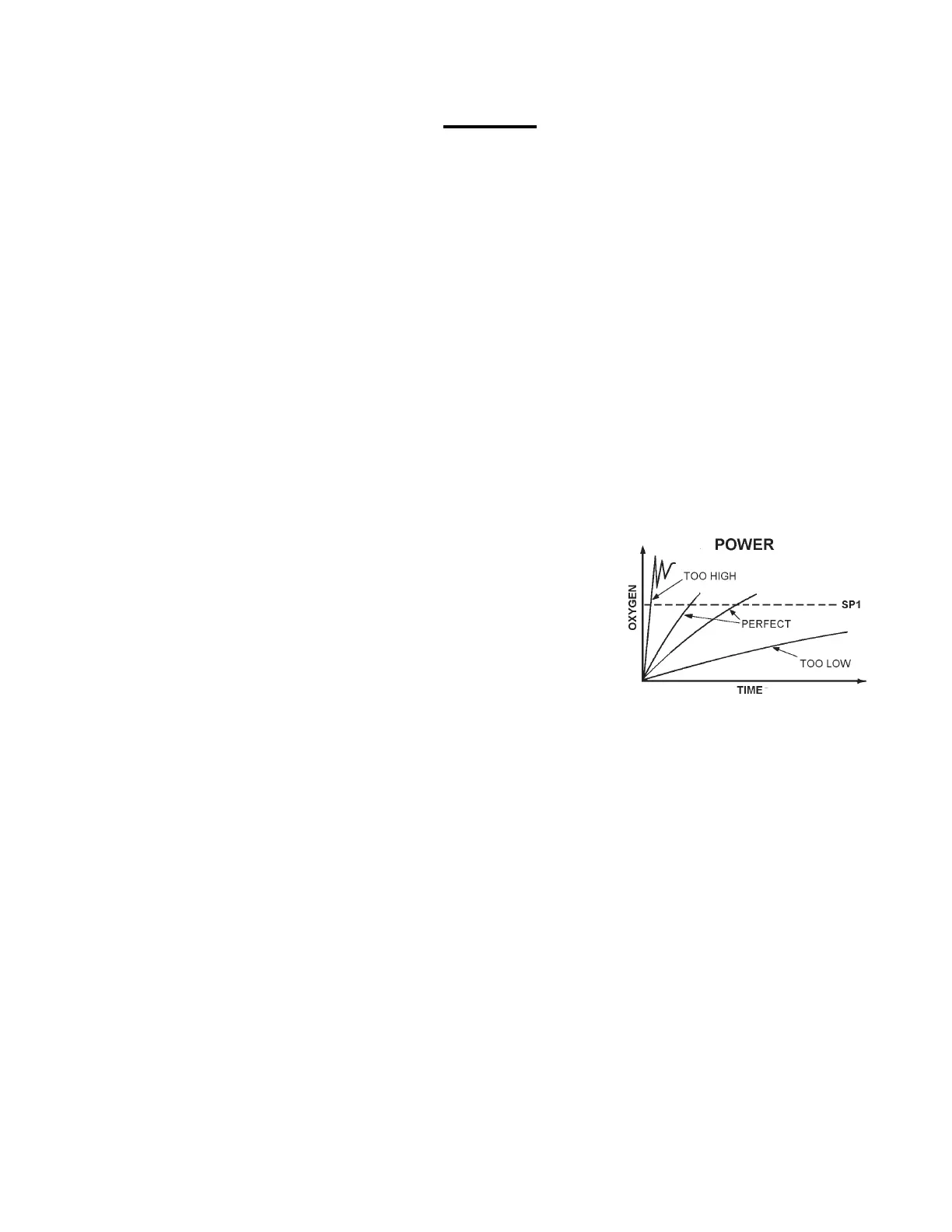

POWER

First adjust power. Power is

the only control parameter not set in

program mode. Once power is set,

other control parameters may be

tuned.

Power is a function of infusion

rate. The more gas infused per unit

time, the higher the power. Infusion

rate is adjustable up to 350 SCFH

(Standard Cubic Feet an Hour).

Infusion rate is a function of

gas supply delivery pressure. The

higher the pressure, the faster the

infusion rate. Adjust the amount of

pressure to the approximate de-

sired infusion rate and fine tune with

the needle valve on the front panel.

Gas supply delivery pressure is set

at the pressure regulator on gas

source. Infusion rate is dependent

on the pressure of the gas coming

from the compressed gas source.

Never exceed 40 PSIG.

Proox 360 power must roughly

match dynamic gas load of cham-

ber. Too little power and it takes

forever to reach set point. Too much

power and control is unstable.

The bigger the chamber, the

more power (gas) it takes. For

example, a small baby incubator

might take 2-5 SCFH , but a tissue

culture incubator might take 10-30

SCFH.

The leakier the chamber, the

more power (gas) it takes. For

example, an incubator with a tight

seal might take 10 SCFH, but one

with a loose seal might take 20

SCFH.

There are methods to calcu-

late power, but it's faster and easier

to adjust power empirically. Watch

the control process and adjust infu-

sion rate so Proox 360 is able to

deliberately push oxygen from am-

bient to past set point under normal

load conditions.

Most jobs can be tuned over a

relatively wide power range. Once

the other control parameters are

tuned, however, any change in the

power/load balance may require re-

tuning those parameters.

STEPS:

1. Set gas supply delivery pressure.

Range 0-40 PSIG. For best

results use 15-20 PSIG.

2. Watch the number in work mode

approach the set point. If too fast

and unstable, turn the needle

valve counterclockwise to lower

the infusion rate. If too slow, turn

the needle valve clockwise to

increase the infusion rate. Never

exceed 40 PSIG.

ON/OFF CONTROL

Crude basic control. Suitable

when precise oxygen levels are not

necessary.

Infusion stops when oxygen

reaches setpoint and resumes only

when oxygen drifts back past setpoint.

Output is either 100% or 0%. Oscil-

lations are natural.

The only tune adjustment is

the dead band width. Dead band

width is distance between on-to-off

point and off-to-on point above and

below setpoint. Defines where no

switching occurs, but oscillation

does occur.

The larger the dead band width,

the larger the oscillation, but the less

switching on and off. Maximize the

dead band width to minimize wear

and tear on equipment. Set for larg-

est acceptable oscillation.

The smaller the dead band

width, the less oscillation, but the

more wear and tear.

15

Proox model 360

version 1.0

Loading...

Loading...