29

Factory configuration

Drive factory settings

The ER12 is factory-set for the most common operating conditions (motor rating according to drive rating):

• Display: drive ready (rdY) motor stopped or motor frequency reference while running

• Automatic adaptation of the deceleration ramp in the event of overvoltage on braking.

• No automatic restarting after a detected fault is cleared

• Logic inputs:

- LI1: forward (2-wire transitional control), start drive

- LI2, LI3, LI4: no assignment

• Logic output: LO1: no assignment

• Analog input: AI1 (0 to + 5 V) speed reference

• Relay R1: the contact opens in the event of a detected fault (or drive off)

• Analog output AO1: no assignment

If the above values are compatible with the application, the drive can be used without changing the settings.

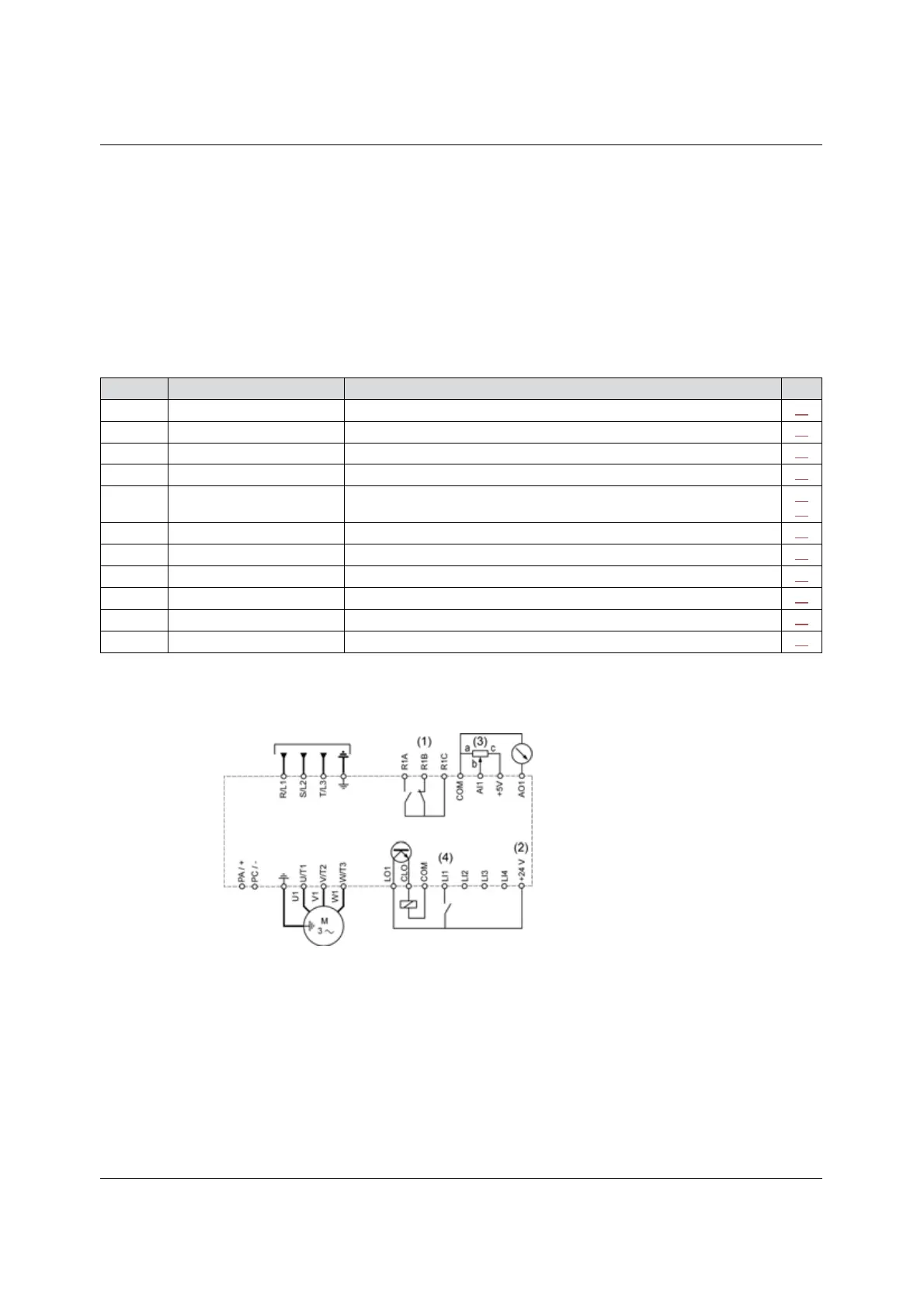

Drive factory wiring diagram

(1) R1 relay contacts, for remote indication of the drive status.

(2) Internal + 24 V DC. If an external source is used (+ 30 V DC maximum), connect the 0 V of the source to the COM terminal, and do not

use the + 24 V DC terminal on the drive.

(3) Reference potentiometer SZ1RV1202 (2.2 k

Ω) or similar (10 kΩ maximum).

(4) Forward

Code Description Value page

bFr Standard motor frequency 50 Hz 44

UnS Rated motor voltage 230 V 55

ACC Acceleration 3 seconds 62

dEC Deceleration 3 seconds 62

LSP Low speed 0 Hz 44

75

HSP High speed 50 Hz 76

Ctt Motor control type Standard U/F law 55

UFr IR compensation (law U/F) 100% 56

Ith Motor thermal current equal to nominal motor current (value determined by drive rating) 80

SdC1 Automatic DC injection current 0.7 x nominal drive current, for 0.5 seconds. 65

SFr Switching frequency 4 kHz 57

ER12-.../3K/B

3-phase

motor

Source

Loading...

Loading...