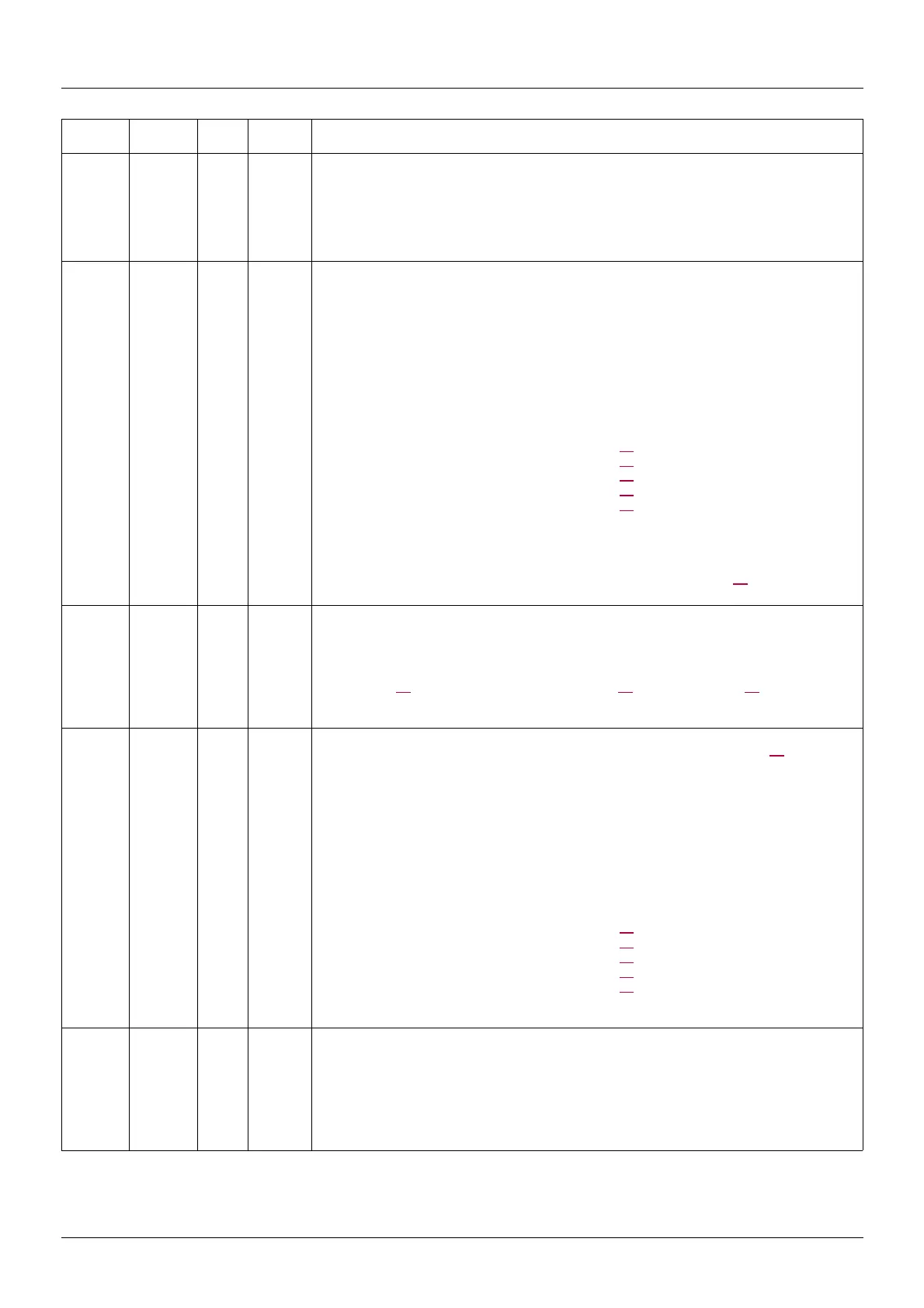

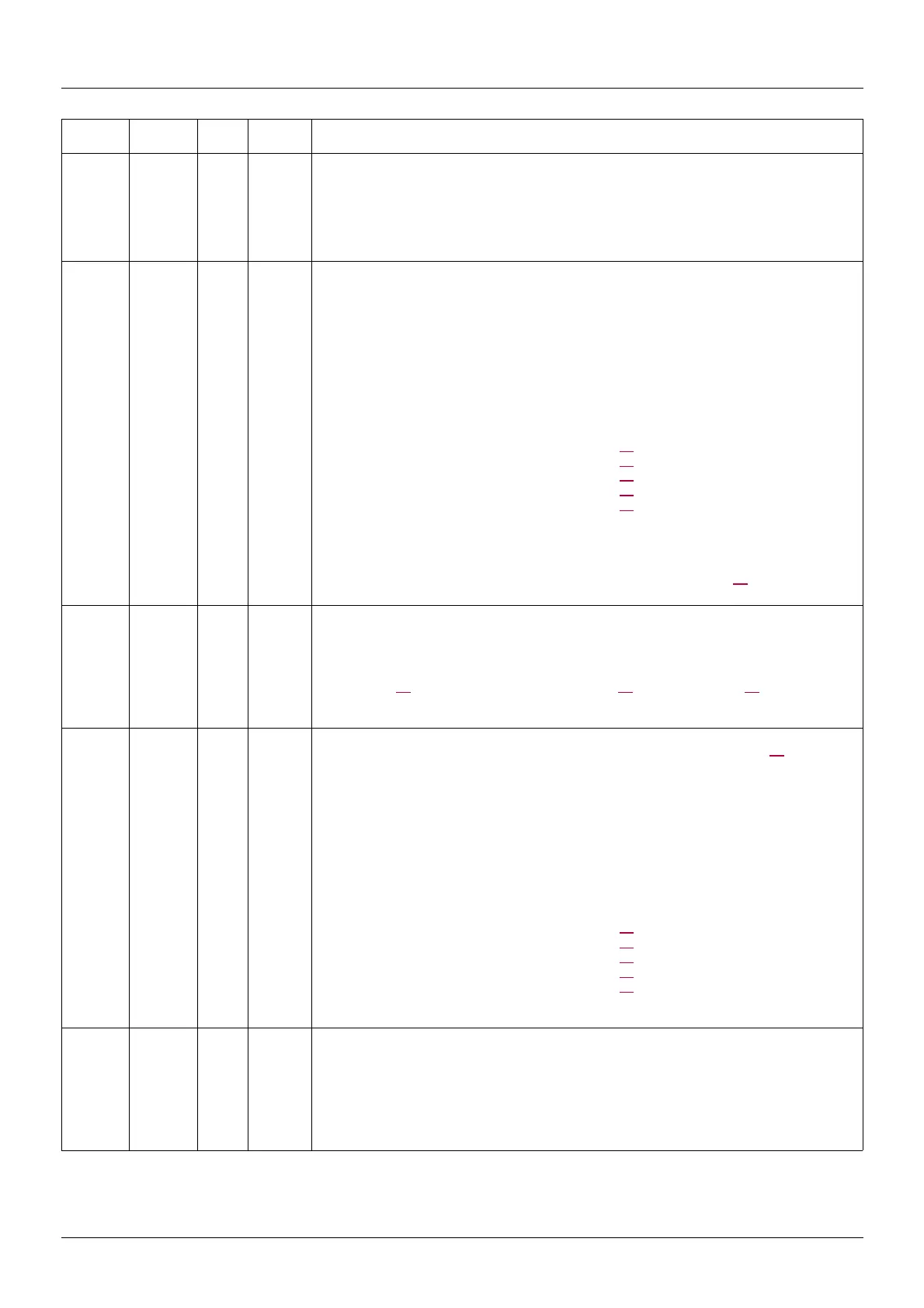

40

Configuration and adjustment variables

Modbus

address

CANopen

address

Code

Read/

Write

Name/Description/Possible values

11201 2052 / 2 Stt R/WS Normal stop mode

Factory setting: 0

Stop mode on disappearance of the run command or appearance of a stop command.

0 = "rMP": On ramp

1 = "FSt": Fast stop

2 = "nSt": Freewheel stop

3 = "dCI": DC injection stop

11204 2052 / 5 FSt R/WS Fast stop via logic input

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

If LAC = L3, the following assignments are possible:

171 = "Cd11": bit 11 of the CMD control word (page 19) written by Modbus or CANopen

172 = "Cd12": bit 12 of the CMD control word (page 19) written by Modbus or CANopen

173 = "Cd13": bit 13 of the CMD control word (page 19) written by Modbus or CANopen

174 = "Cd14": bit 14 of the CMD control word (page 19) written by Modbus or CANopen

175 = "Cd15": bit 15 of the CMD control word (page 19) written by Modbus or CANopen

The stop is activated when the logic state of the input changes to 0 and the control word bit

changes to 1. The fast stop is a stop on a reduced ramp via parameter dCF. If the input falls

back to state 1 and the run command is still active, the motor will only restart if 2-wire level

control has been configured (tCC = 2C and tCt = LEL or PFO, see page 33). In other cases, a

new run command must be sent.

11230 2052 / 1F dCF R/WS Coefficient for dividing the deceleration ramp time for fast stopping

Unit: 1

Factory setting: 4

Adjustment range: 0 to 10

Parameter accessible if a fast stop has been assigned by one of the following parameters:

Stt/FSt (page 40) or EPL/OHL/OLL/SLL/COL (page 59) or LFL/StP (page 59).

Ensure that the reduced ramp is not too low in relation to the load to be stopped.

The value 0 corresponds to the minimum ramp.

11203 2052 / 4 dCI R/WS DC injection via logic input

Note This function is incompatible with the "Brake control" function (see page 14).

Factory setting: 0

0 = "nO": Not assigned

129 = "LI1": Logic input LI1

130 = "LI2": Logic input LI2

131 = "LI3": Logic input LI3

132 = "LI4": Logic input LI4

133 = "LI5": Logic input LI5

134 = "LI6": Logic input LI6

If LAC = L3, the following assignments are possible:

171 = "Cd11": bit 11 of the CMD control word (page 19) written by Modbus or CANopen

172 = "Cd12": bit 12 of the CMD control word (page 19) written by Modbus or CANopen

173 = "Cd13": bit 13 of the CMD control word (page 19) written by Modbus or CANopen

174 = "Cd14": bit 14 of the CMD control word (page 19) written by Modbus or CANopen

175 = "Cd15": bit 15 of the CMD control word (page 19) written by Modbus or CANopen

Braking is activated when the logic state of the input or control word bit is at 1.

11210 2052 / B IdC R/W Level of DC injection braking current activated via logic input or selected as stop mode

Note: This setting is not related to the "automatic standstill DC injection" function.

Unit: 0.1 A

Factory setting: 0.7 In (1)

Adjustment range: 0 to In (1)

After 5 seconds the injection current is peak limited at 0.5 Ith if it is set at a higher value.

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the

drive rating plate.

Loading...

Loading...