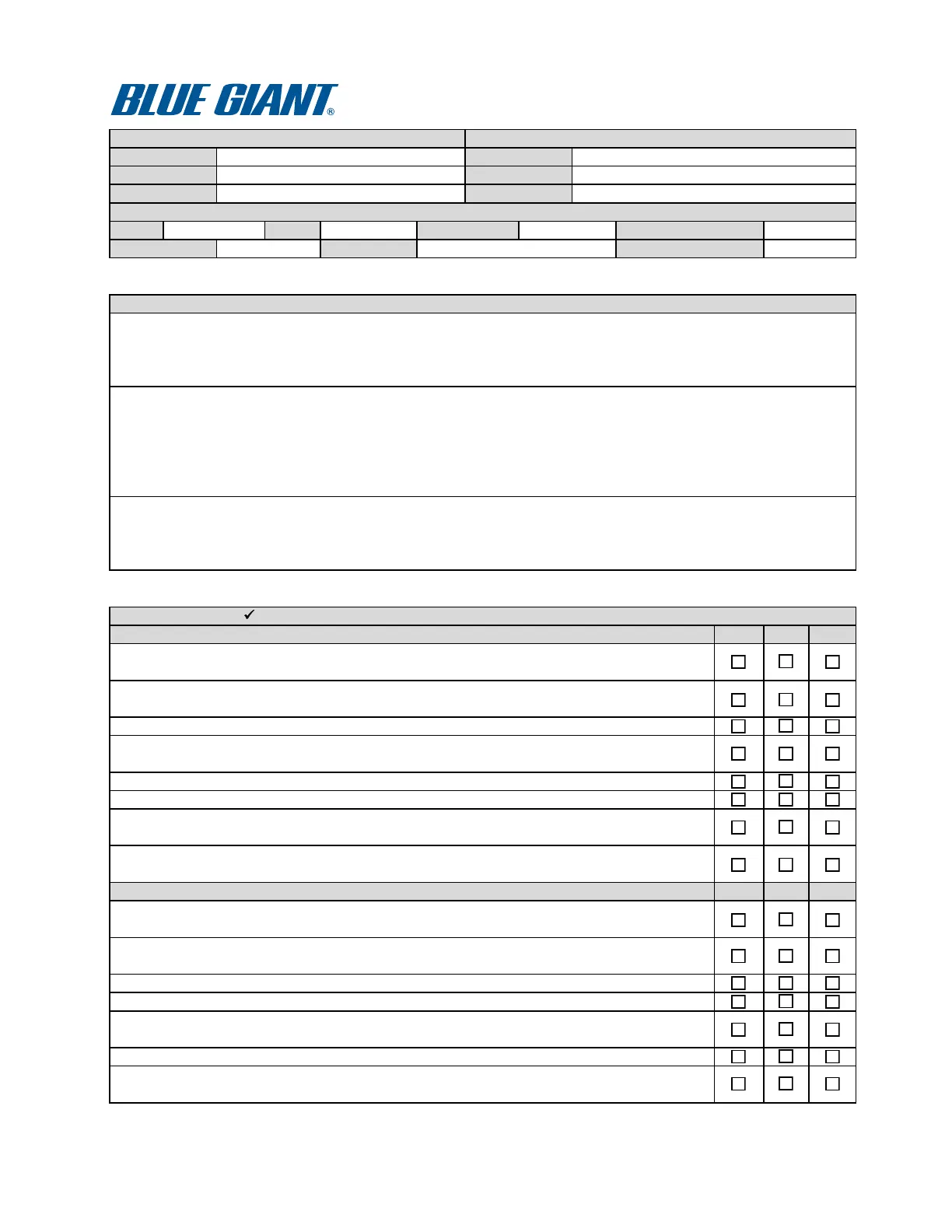

VERSION G PAGE 1 OF 2

MODEL: SERIAL:

P F C

P F C

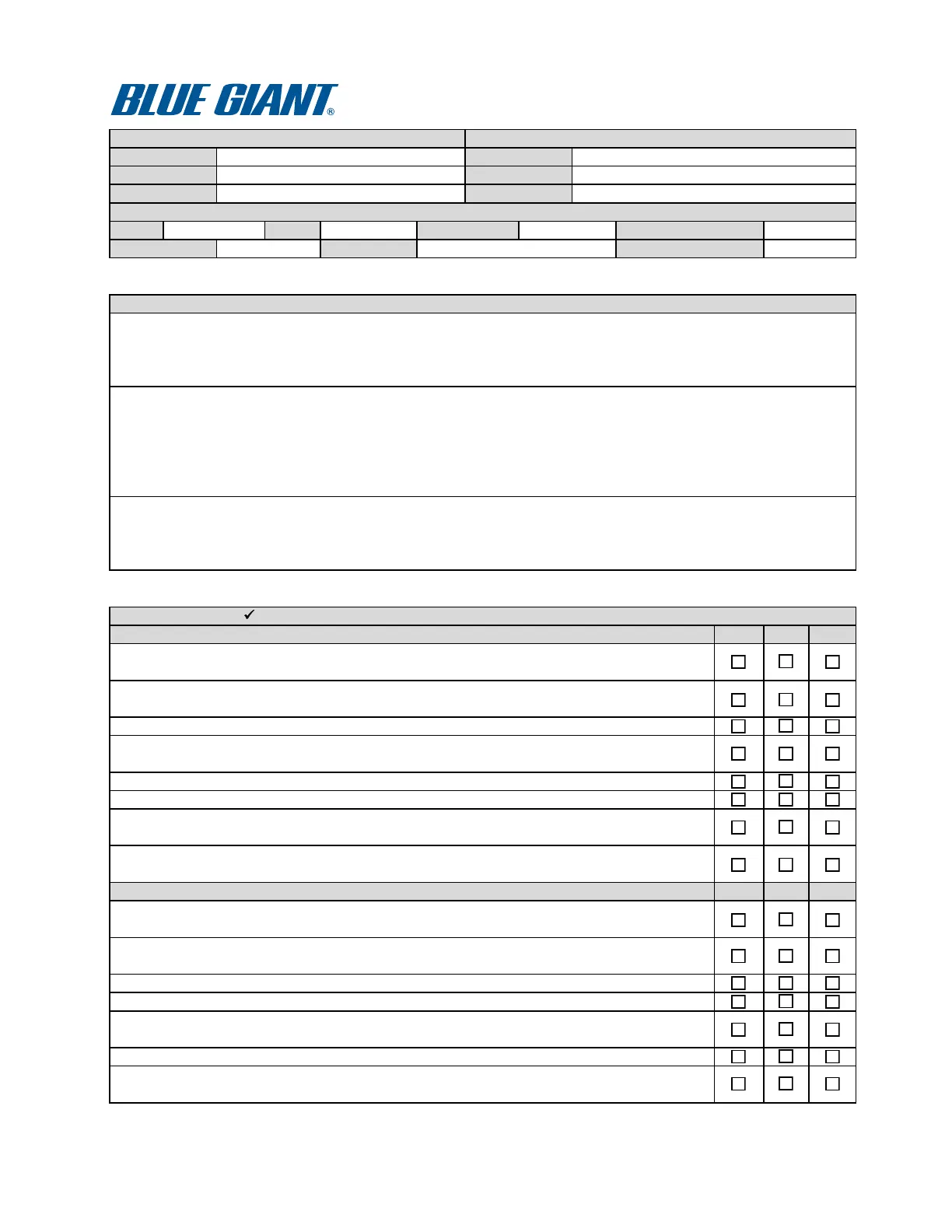

Instrument panel is clean and free of debris and dash display is funconal.

Operator le side control arm steering wheel func properly.

Emergency lower buon operates properly.

Ensure gate switches disable travel/li and lower funcons and g lights on the front and rear of

the vehicle.

HOUR METER:

BATTERY SPEC.: OPTIONS: PREVIOUS INSPECTION:

Plarm guard rails are undamaged and gates open / close freely.

Chains are adequately lubricated and are not dry or rusty.

Mast cover plates are in place and securely hed for each secon.

Coned on page 2

FREQUENT INSPECTIONS: The owner and user are required by ANSI A92.6 to ensure frequent inspec of the BG Zero Task

Support Vehicle occur and are performed in accordance with the following points: 1. If purchased used unless it's determined

that the frequent and annual inspec are current. 2. The BG Zero Task Support Vehicle has been in service for three (3)

months or 150 hours, whichever comes rst. 3. The BG Zero Task Support Vehicle has been out of service for a period longer

than three (3) months. inspec is to be performed by a mechanic that is ed and authorized to perform service on the

BG Zero Task Support Vehicle. All service records must be maintained.

INSPECTION REQUIREMENTS per ANSI A92.6 (ANNUAL AND FREQUENT)

ANNUAL INSPECTION: The owner and user are required by ANSI A92.6 to ensure annual inspec of the BG Zero Task Support

Vehicle occur and are performed no later than 13 months from the date of prior annual inspec or every 700 hundred hours

of use, whichever occurs rst. This annual inspec is to be performed by a mechanic that is ed and authorized to

perform service on the BG Zero Task Support Vehicle. All service records must be maintained.

NOITAMROFNI RESU DNE / RENWONOITAMROFNI RELAED

COMPANY:

ADDRESS:

Annual Inspec�on Report

INSTRUCTIONS: Refer to service/maintenance manuals for specc informa regarding inspec procedures and criteria.

Indicate in the appropriate space as each item has been performed. If the item is found to be not acceptable, describe each

discrepancy on an addi page and aach to the form. Immediate acon must be taken to correct all discrepancies. The

vehicle shall not be placed in service un all discrepancies have been corrected.

CITY/STATE/ZIP:

COMPANY:

ADDRESS:

CITY/STATE/ZIP:

MAST SIZE:

VEHICLE INFORMATION:

Operator right side control arm funcons properly. Horn / travel / li / lower / accelerator buons are

func.

Put a

in the column that applies: P = Passed Inspec�on , F = Failed Inspec�on, C = Corrected

Drive and operate machine to test all funcons. Ensure controls operate properly and return to "" or

neutral when released.

Ensure emergency power disconnect switch deactes all movement and power and that the deadman

foot switch operate properly.

FUNCTIONS and CONTROLS

Mast sec are free of visual evidence of damage. Mast chains and cables are inspected per the

Service and Maintenance Manual.

OPERATOR PLATFORM ASSEMBLIES

The drive wheel returns to "neutral" (straight forward) whe

n powering up the vehicle and is accurately

depicted on the LCD display.

All nuts, bolts, pins, shas, covers, bearings and wear pads are checked for proper installa, and do

not have excessive wear, cracks or distoron.

Mast wiring harnesses are properly installed, seated in their pulleys and that there are no frayed or

broken strands.

Mast operates smoothly to full height and descends smoothly. Ensure speed cutbacks occur at

appropriate heights per the maintenance manual.

Page 2-6

Loading...

Loading...