3 Application

The teleservice kit enables the control and maintenance of frequency inverters via a

telecommunication connection.

From a central terminal, frequency inverters can be parameterized, controlled and

monitored.

Via teleservice, the staff on site can be supported during commissioning.

The use of the teleservice kit offers the following advantages:

− Errors in a system can be detected and repaired quickly. Thus less standstill times.

− Flexible, operation-specific plant monitorin

g and reporting of the plant states to the

operating staff.

− Continuous plant monitorin

g for assessment of the production process and for

preventive maintenance.

− Availability and efficiency of customer service is increased by remote commissioning

and maintenance.

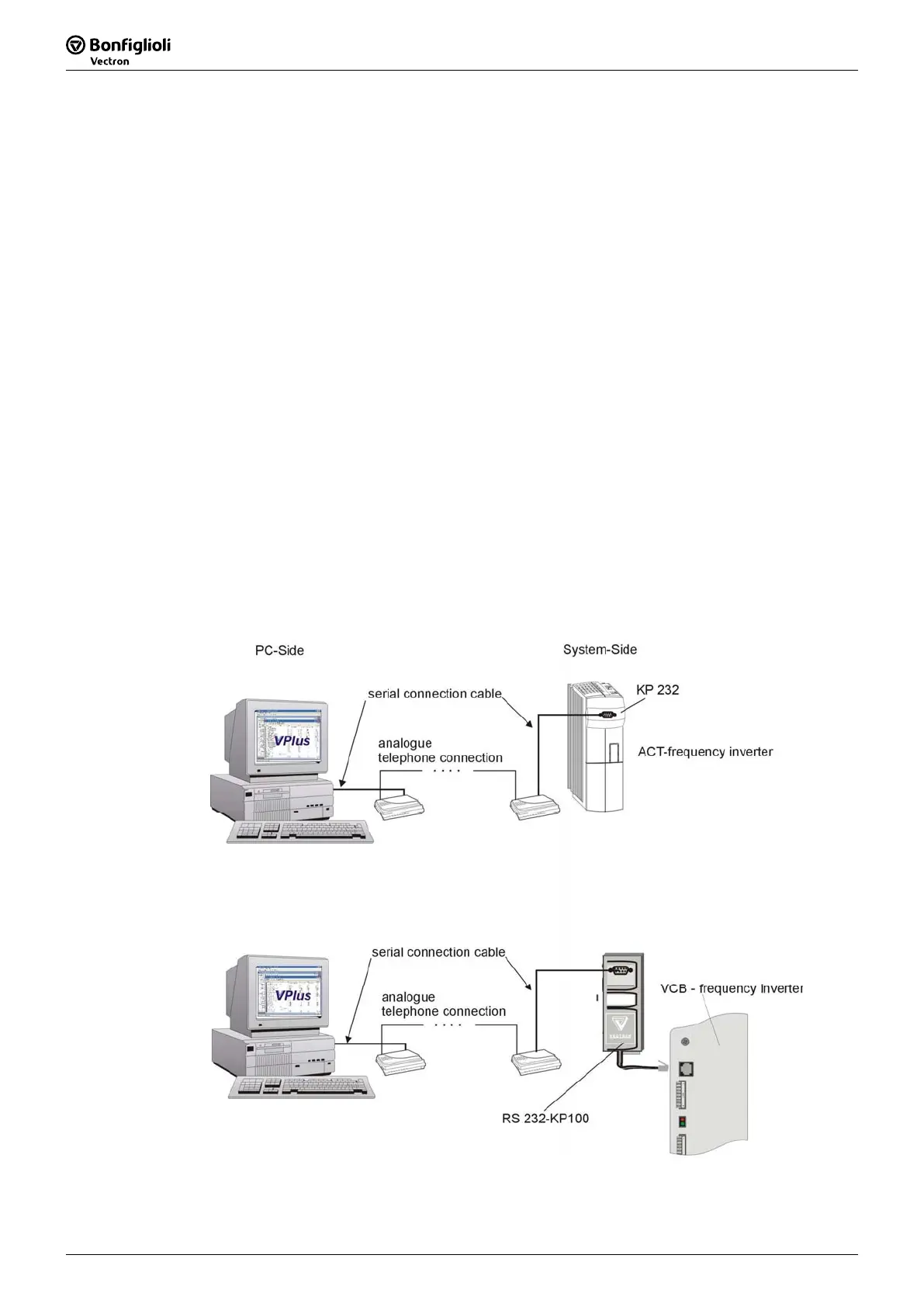

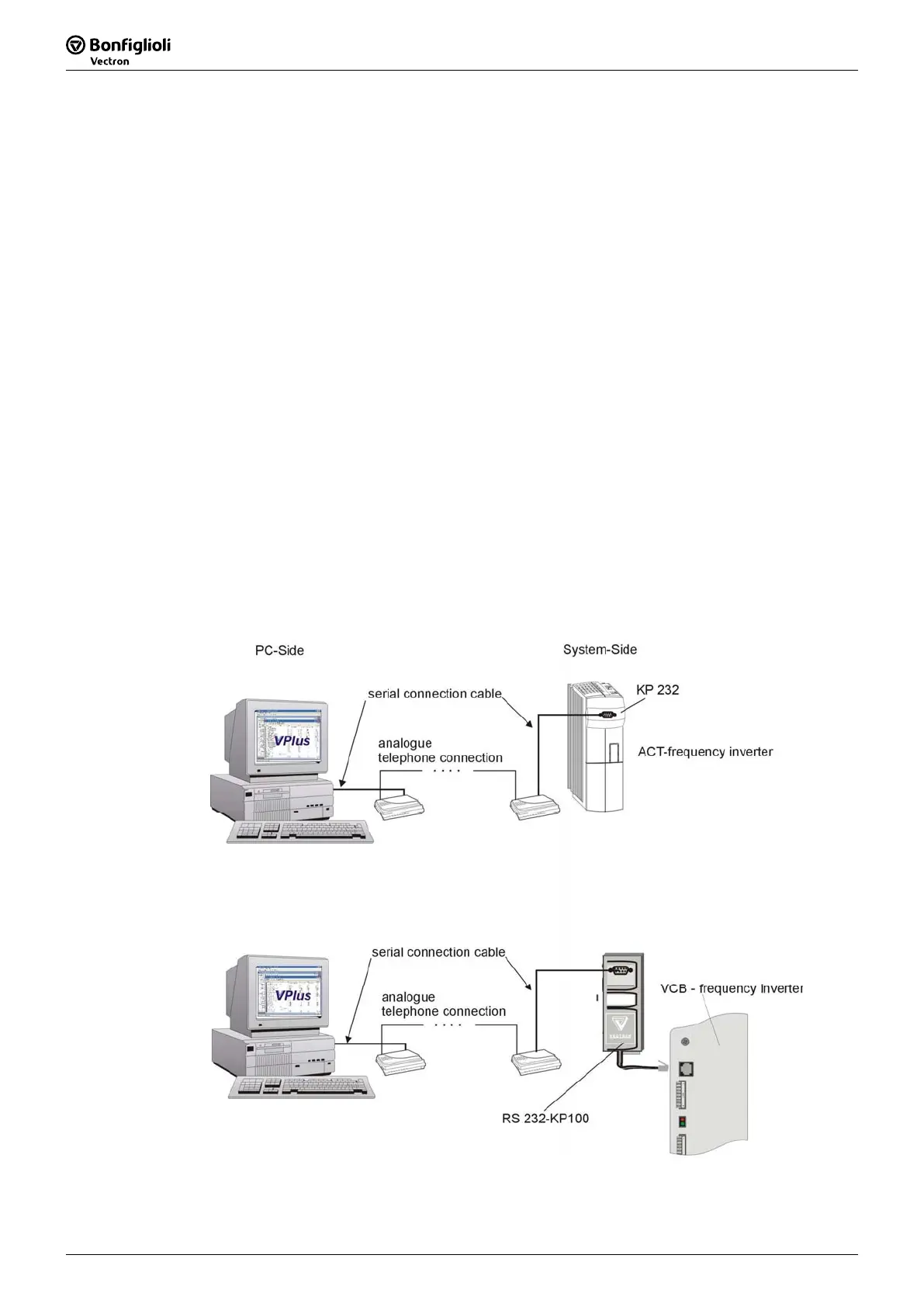

Establishment of communication connection

The communication connection is shown in the following diagram. The control software

VPlus is installed on a service terminal, and the dialing process is started.

The modem connected to the PC establishes the connection to the modem on the plant

side via an analog telephone line. Now, the frequency inverter is accessed via a serial

cable and an interface converter.

When the connection was established successfully, the data of the frequency inverte

r

are downloaded and represented in VPlus.

Note: In addition to analo

g modems, the control software VPlus also supports

several other communication media. For more information, refer to the

annex.

11/075

Loading...

Loading...