19

Using the Head Assembly Lock Pin

To avoid possible injury,

disconnect plug from power

s

ource before performing any assembly,

adjustments or repairs.

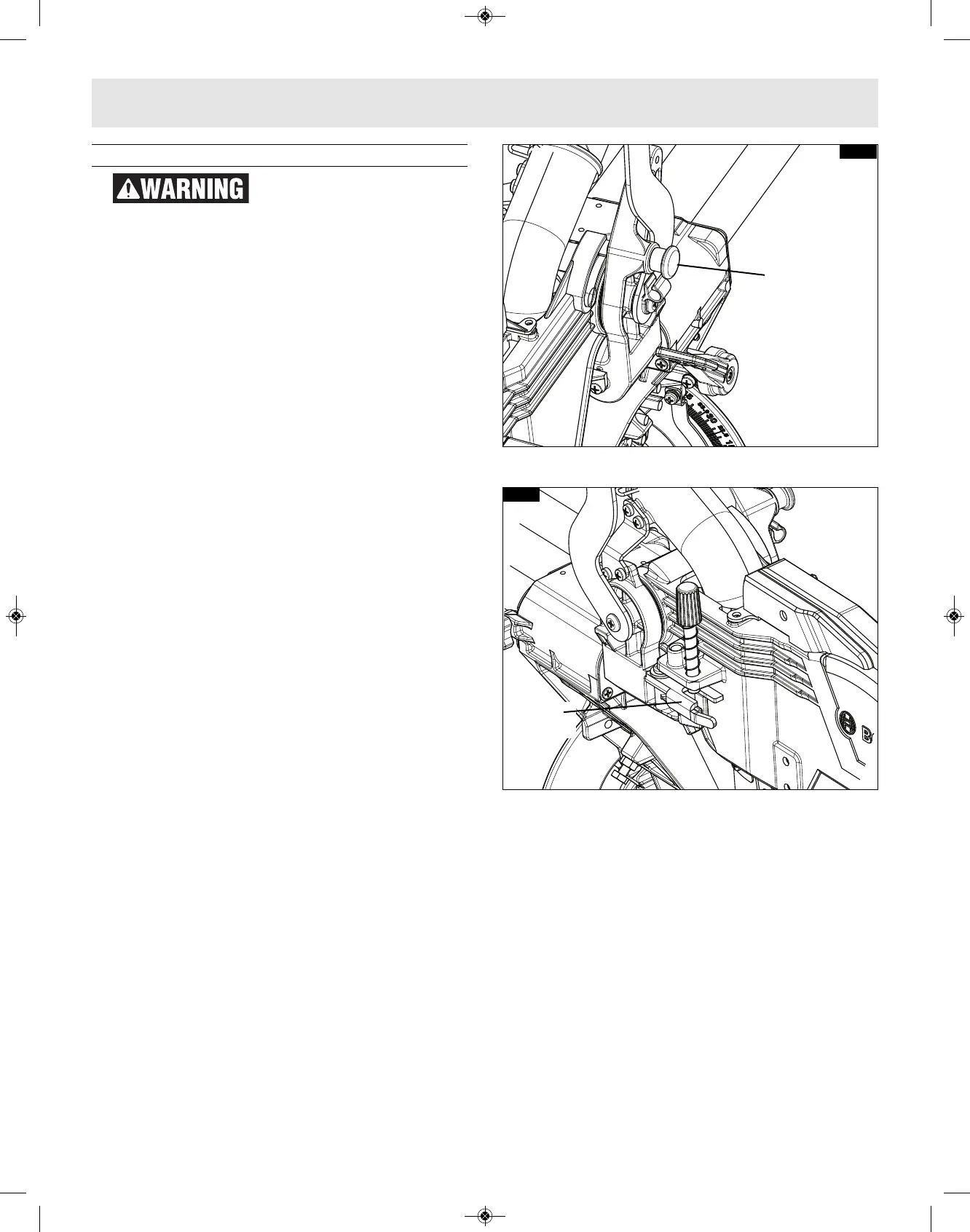

HEAD ASSEMBLY LOCK PIN

The head assembly lock pin (figure 8) is used to

hold the saw’s head assembly in the DOWN

position. This position prevents the head from

bouncing up and down during transportation. This

also makes the saw more compact for lifting and

storage. This position is also required for some

calibrating procedures.

TO ENGAGE THE HEAD ASSEMBLY LOCK PIN:

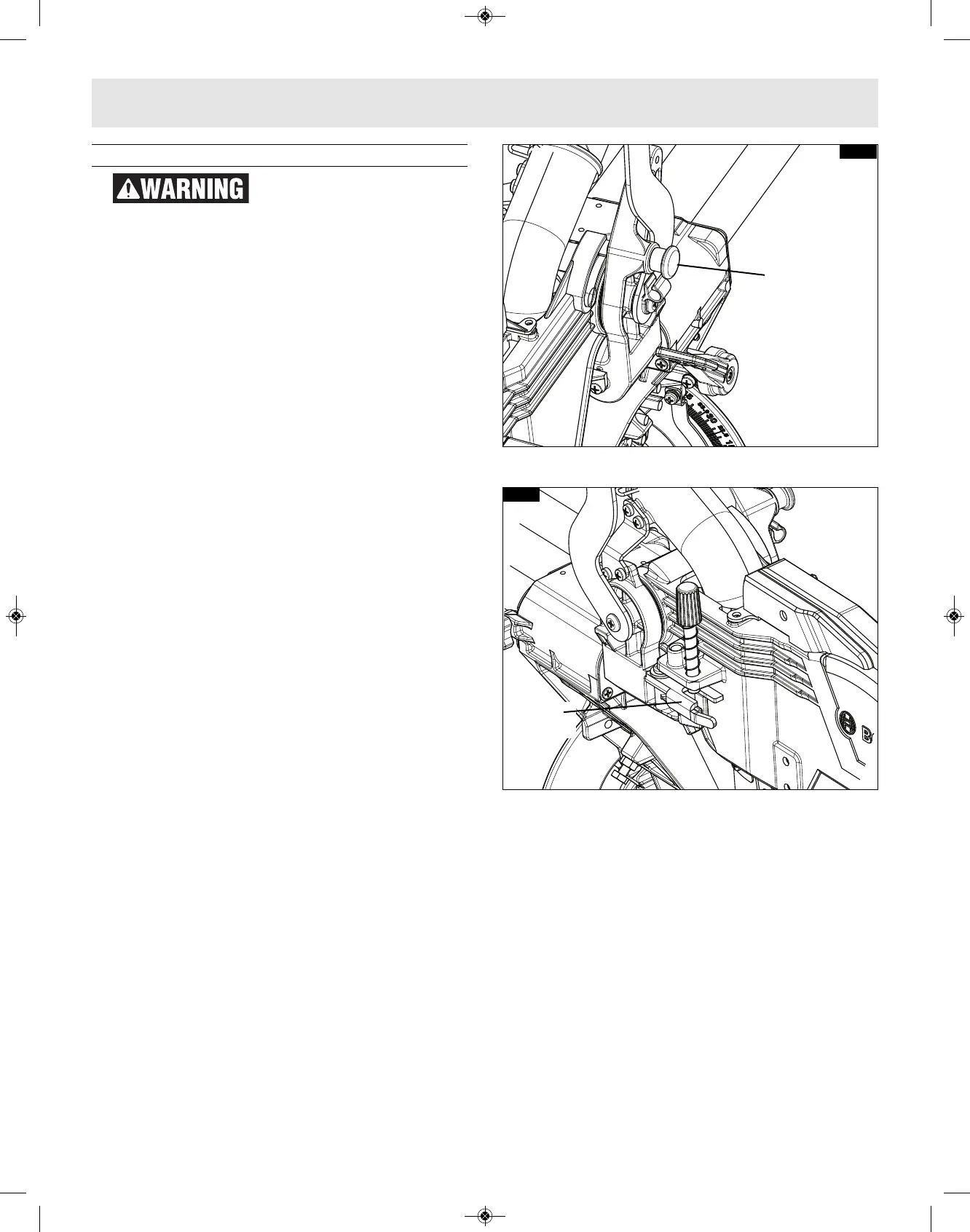

1. Check that the depth stop plate is disengaged,

pressed in against saw head, (figure 9).

2. Grasp the saw’s main handle and press down on

the head assembly.

3. While pressing the saw head down, push in on

the head assembly lock pin, (figure 8). Release

the head assembly. The head will be locked in

the DOWN position.

TO DISENGAGE THE HEAD ASSEMBLY

LOCK PIN:

1. Grasp the main handle and press down on the

head assembly.

2. While pressing the head down, pull out the head

assembly lock pin. Release the lock pin, but

maintain your grip on the main handle. Slowly

allow the spring-loaded saw head to come up to

the top of its travel and then release the handle.

FIG. 8

FIG. 9

Head

Assembly

Lock Pin

Depth

Stop Plate

Assembly

Loading...

Loading...