1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

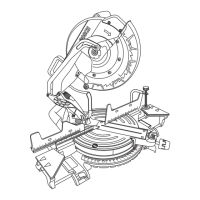

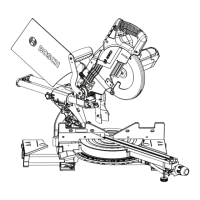

CM10GD

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

IMPORTANT

Read Before Using

IMPORTANT

Lire avant usage

IMPORTANTE

Leer antes de usar

For English Version

See page 2

Version française

Voir page 62

Versión en español

Ver la página 124

Call Toll Free for Consumer Information and Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente,

appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio