FRONT AXLE

KUKJE MACHINERY CO., LTD.

60

4. CHECKING, DISASSEMBLING AND SERVICING

< Clearance between differential case and

differential pinion >

1. Measure the differential pinion boss O.D. with an

outside micrometer.

2. Measure the differential case bore I.D. with a

cylinder gauge, calculate the clearance.

3. If the clearance exceeds the allowable limit,

replace faulty parts.

Factory spec.

0.032 to 0.068 mm

0.00126 to 0.00268 in.

Clearance between

differential case and

differential pinion

Allowable

limit

0.2 mm

0.0079 in.

Differential case

bore I.D.

Factory spec.

15.000 to 15.018 mm

0.59055 to 0.59126 in.

Differential

pinion O.D.

Factory spec.

14.950 to 14.968 mm

0.58858 to 0.58929 in.

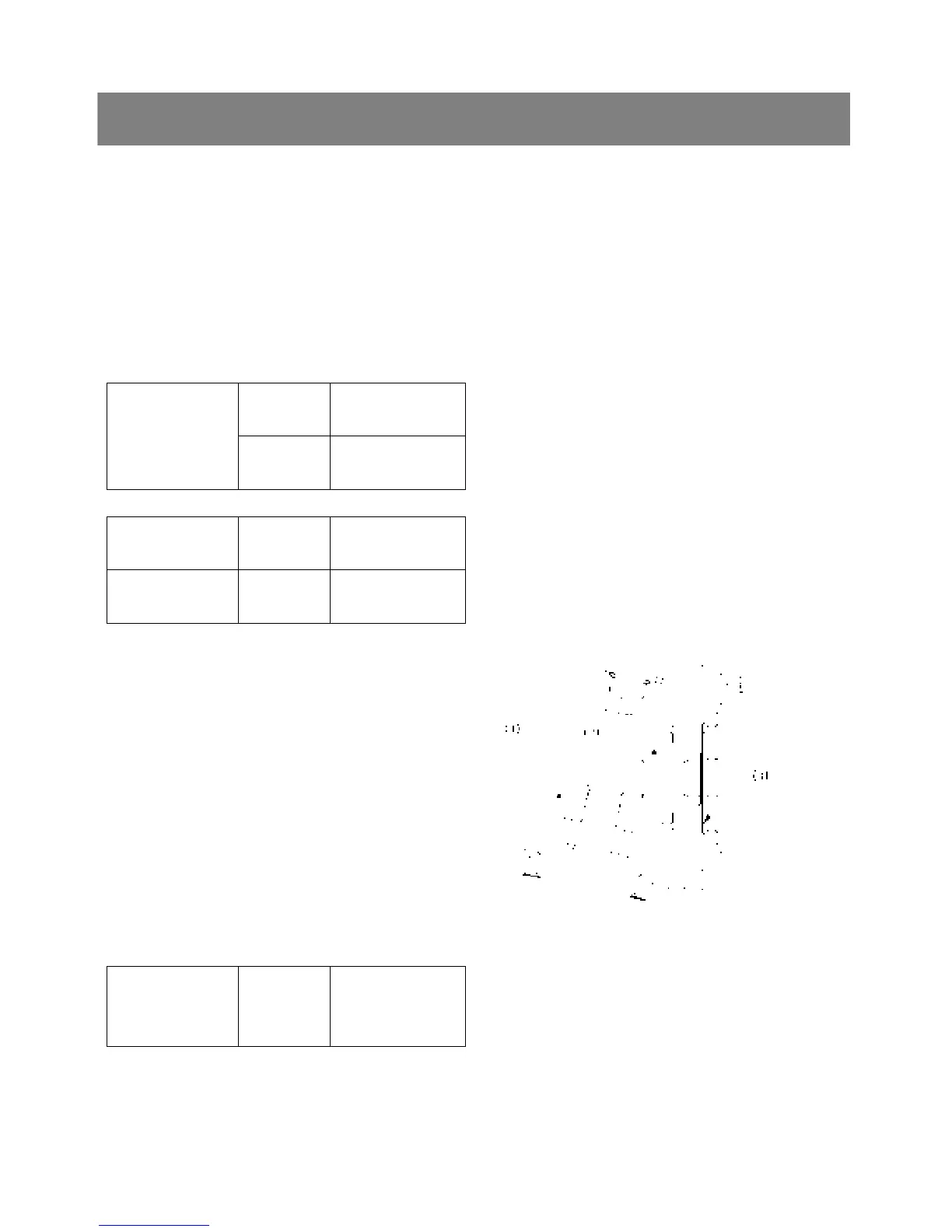

< Backlash between 10T bevel gear and 16T bevel

gear >

1. Stick a strip of fuse to three sports on the 16T

bevel gear(1) with grease.

2. Fix the front axle case, bevel gear case and front

gear case.

3. Turn the axle.

4. Remove the bevel gear case from front axle case

and measure the thickness of the fuses with an

outside micrometer.

5. If the backlash is not with in the factory

specifications, adjust with shim(3).

Backlash between

10T bevel gear and

16T bevel gear

Factory spec.

0.1 to 0.3 mm

0.2 0.004 to 0.012 in.

9 Tooth contact : More than 35%

9 Thickness of adjusting shims (3) :

0.8mm(0.031in.), 1.0mm(0.039in.),

1.2mm(0.047in.), 1.4mm(0.055in.)

*. PART NAME

1) 16T Bevel gear 2) 10T Bevel gear

3) Shim

Loading...

Loading...