10

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

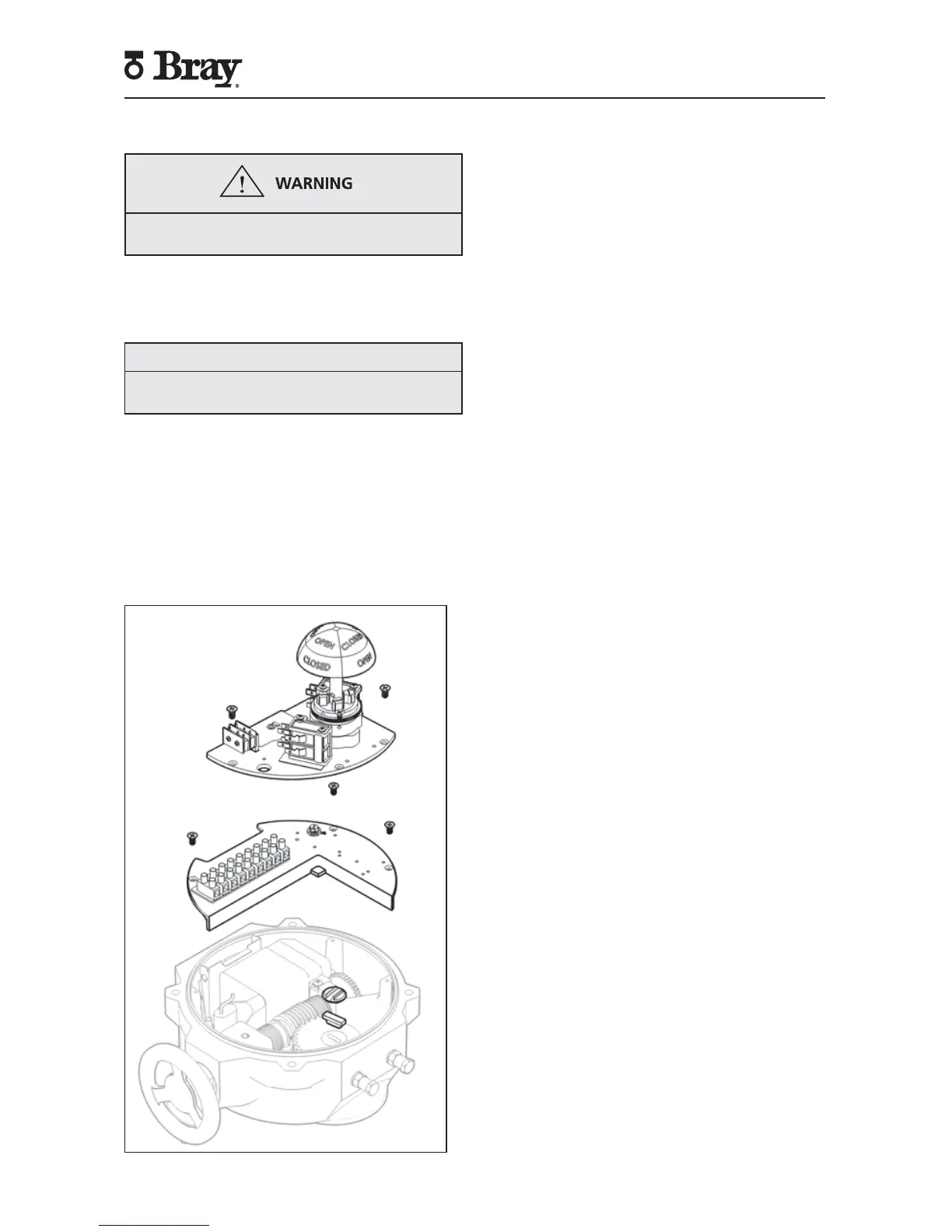

Disassembly and Assembly

Turn off all power and lockout/tag out service panel

before installing or modifying any electrical wiring.

1. Disconnect external wiring from terminals.

2. Disconnect motor wires from the main terminal

strip (motor neutral, open, and close)

NOTICE

Removal of switch plate with torque switches will

void warranty.

3. To remove the switch plate:

a. Follow after disconnecting external wires and

motor wires.

b. Unscrew the seven Phillips head mounting

screws.

c. Lift the switch plate(s) out as an assembly with

the indicator shaft attached.

d. NOTE: Do not misplace shaft coupler, insert,

or mounting screws.

Figure 10. S70, Actuator Size 003, 006 – switch plate removed.

4. To replace the switch plate:

a. Engage handwheel.

b. Place insert into the worm segment.

c. Place and center shaft coupler onto insert.

d. Align indicator shaft with groove in coupler

and gently place switch plate into position.

e. Check alignment of override switch activation

pin.

f. Slowly turn handwheel to ensure that the

indicator shaft is fully engaged in coupler.

g. Secure the switch plate with seven Phillips

head mounting screws in a “star” pattern.

h. Disengage the handwheel.

5. To remove the indicator shaft from the switch plate:

a. Follow after removing the switch plate.

b. Remove the retaining ring from the shaft,

located underneath switch plate.

c. Press the shaft out, from the bottom of the

switch plate.

d. NOTE: Provide support to top of switch plate

so that components on top of the switch plate

are not damaged during this procedure.

6. To remove the bearing from the switch plate:

a. Follow after the removing the indicator shaft.

b. Press the bearing from the top of the switch

plate to remove the bearing.

c. To replace, press bearing (700000-72701534)

into switch plate from the bottom of switch

plate.

7. To replace the indicator shaft in the switch plate:

a. Gently press the indicator shaft from the top of

the switch plate until the cams are flush with

the top surface of the switch plate. NOTE:

Provide support for the press fit bearing during

this step.

b. Replace retaining ring (070375-74503534) on

the shaft, located underneath switch plate.

c. Gently press the indicator shaft from the

bottom until the retaining ring is flush with

bottom of the bearing.

d. Test indicator shaft for tight fitment and ease

of rotation.

8. Other switch plate components:

a. Most components can be removed from the

switch plate without removal of the switch

plate.

Loading...

Loading...