17

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

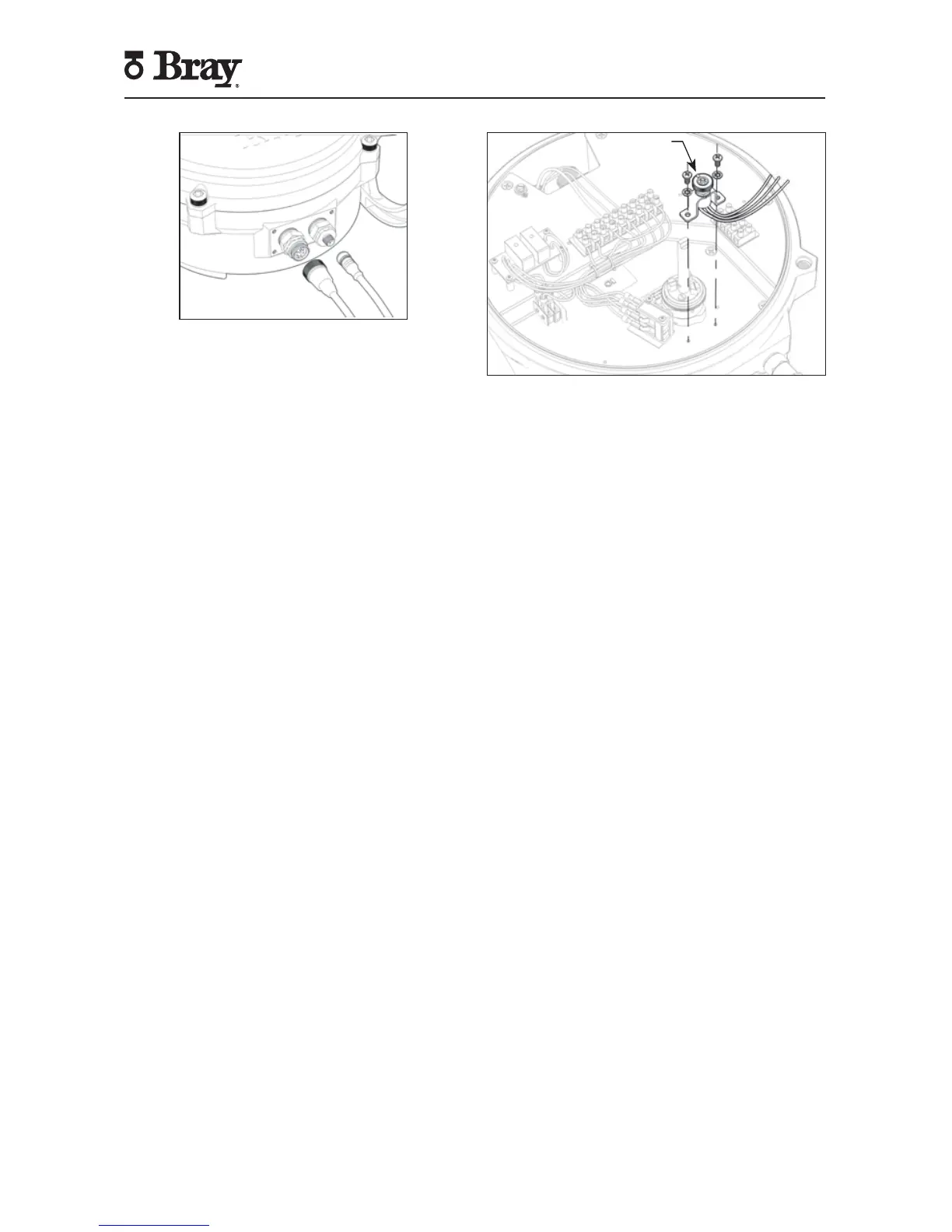

Figure 20. S70 with 5-pin receptacle and corresponding cord set.

Installation Procedure:

1. Screw the receptacle into the actuator conduit entry

using Teflon tape or similar.

2. Wire to the terminal strip according to the wiring

diagram or the field wiring requirements.

NOTES:

• Euro receptacles use 22 AWG wire rated at 250V,

4 Amp. Pin configuration interfaces with European

standards.

• Mini Receptacles use 18 AWG wire rated at 300V, 9

Amp. Pin configuration conforms to ANSI B93.55M.

• Factory will need wiring diagram drawing number

and model of the existing unit if it is to be retrofit with

receptacles. New wiring diagram will be provided

based upon this information.

• Some configurations may limit use of receptacles due

to number of wires entering through the conduit.

External Signal Feedback Potentiometer

Potentiometers are a field or factory installable option

for continuous duty actuators. Actuators which are

not continuous duty do not have a pot gear fitted

on their indicator shafts and must be fitted with a

new indicator shaft in the factory. S70 actuators fitted

with electronics for modulating applications already

fit a potentiometer and cannot fit a second. In this

case, retransmission of position is provided through

the modulating electronics package.

Feedback Potentiometer Kit:

• Potentiometer Assembly

• #6 Cross Drive Pan Head Screws (Qty:2)

• #6 Internal Lockwashers (Qty:2)

• 4-pole Terminal Strip

• Terminal Strip Marker

• Wiring Diagram

Tools Required:

• Screwdriver, 3/16” [5 mm] tip flat blade

• Screwdriver, No.2 Phillips

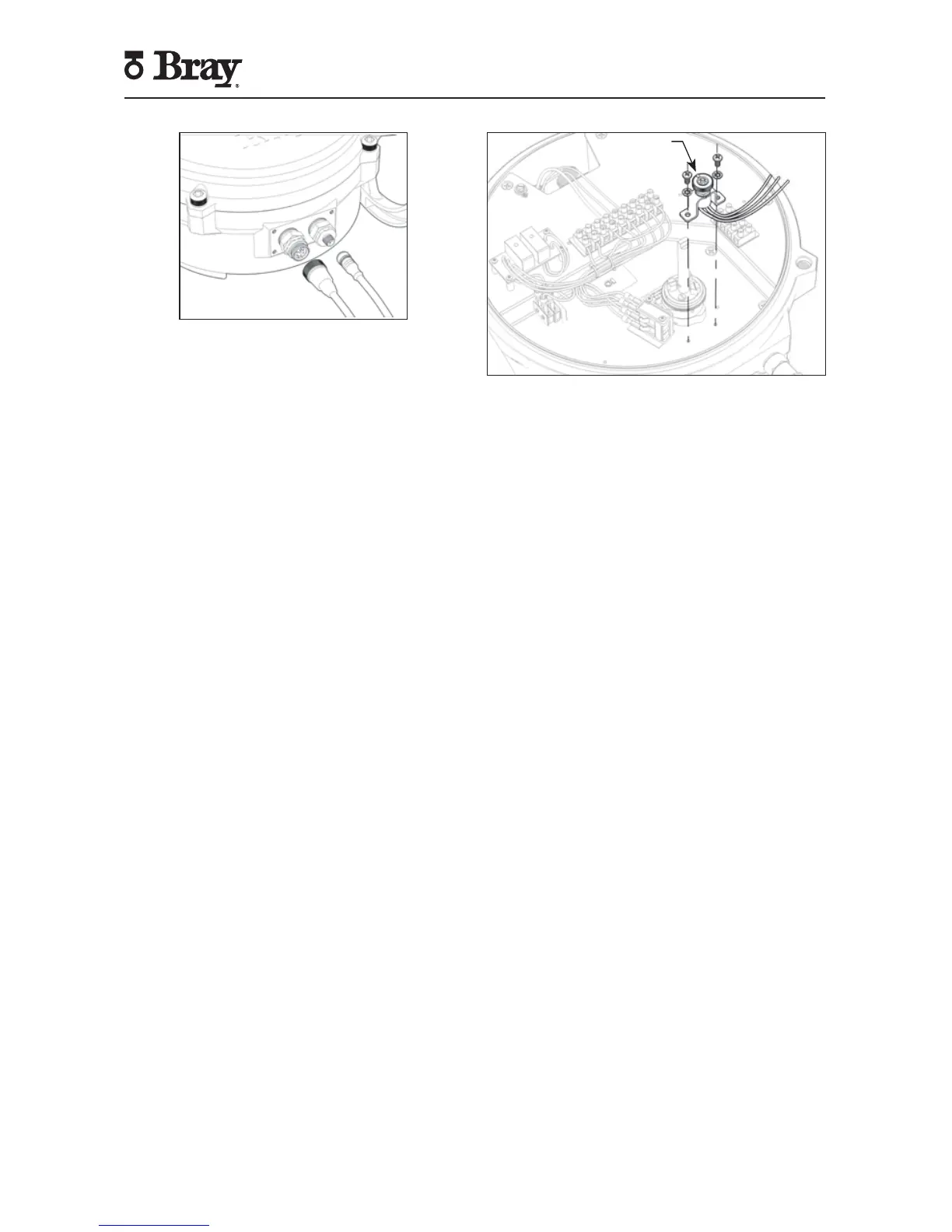

Figure 21. S70 Potentiometer installation.

1. Orient the actuator in the full open (counter

clockwise) position.

2. Install the potentiometer next to the indicator

shaft where two threaded holes are provided for

installation.

3. Align the raised green rib on pot gear with the

center line of the indicator shaft.

4. Push the assembly towards the cam to mesh the

gears, then tighten the mounting screws.

5. Rotate the actuator handwheel so that the red cam

lobe is facing the body of the potentiometer. Make

sure that the cam is not touching the potentiometer

assembly. Readjust the assembly position if necessary.

6. Cut the terminal marker to fit the 4-pole terminal

strip.

7. Mount the 4-pole terminal strip and marker on the

switch plate.

8. Wire the potentiometer to the terminal strip using

the new wiring diagram.

9. Adhere the new wiring diagram sticker to the inside

of the cover.

NOTE:

• Factory will need wiring diagram drawing number

and model of the existing unit if it is to be retrofit

with a potentiometer. New wiring diagram will be

provided based upon this information.

Raised

green rib

Loading...

Loading...