4

Series 70 Electric Actuator

Installation, Operation and Maintenance Manual

Actuation

Manual Operation

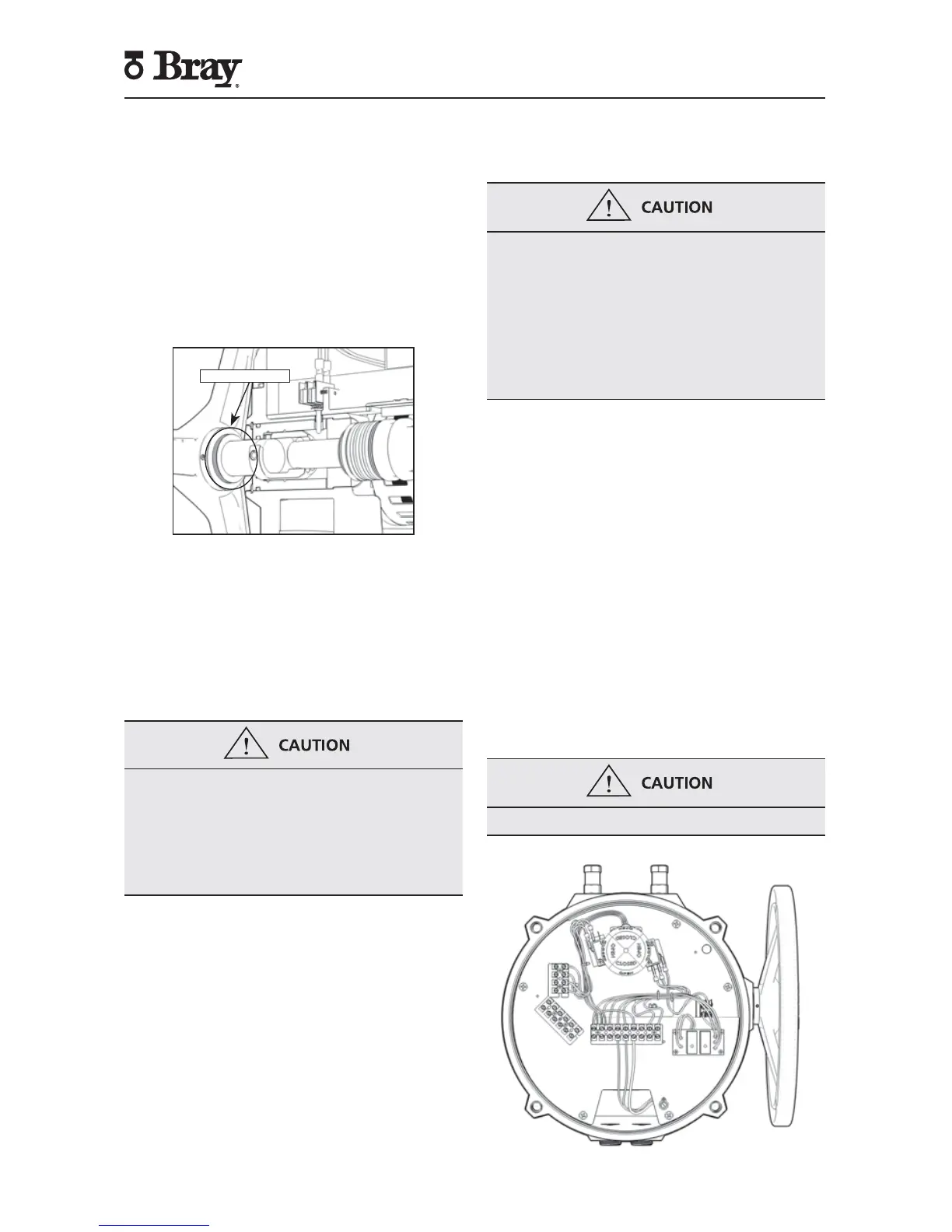

The manual override operates similar to a watch

adjusting knob. To engage the manual override, simply

pull the handwheel to its outermost position. A yellow

stripe is revealed to visually indicate manual override

engagement as shown in Figure 1. The two handwheel

positions, engaged and disengaged, are held in place

with the use of spring plungers. The handwheel remains

in position until physically moved.

Yellow Stripe

Figure 1 - Handwheel is engaged, revealing the yellow stripe.

Once the manual override is engaged, rotating the

handwheel in the clockwise direction will rotate the

output shaft in the clockwise (close) direction and

vice-versa.

To disengage the manual override, the handwheel needs

to be pushed towards the actuator until the ‘yellow

stripe’ is hidden.

A label on the handwheel hub warns users not to

exceed a specific ‘rim pull’ force, for each size of

actuator.

If the ‘rim pull’ force is exceeded, the roll pin securing

the handwheel onto the manual override shaft is

designed to shear, thus preventing serious internal

gearing damage.

Remote Operation

1. Verify that the main electric power supplied to the

actuator is in compliance with the specifications on

the actuator label.

2. Engaging the handwheel before or during the

application of a supply voltage will prevent the

actuator motor from operating.

3. If torque switches are installed in the actuator, an

over-torque condition will prevent the actuator

motor from operating in the direction of fault.

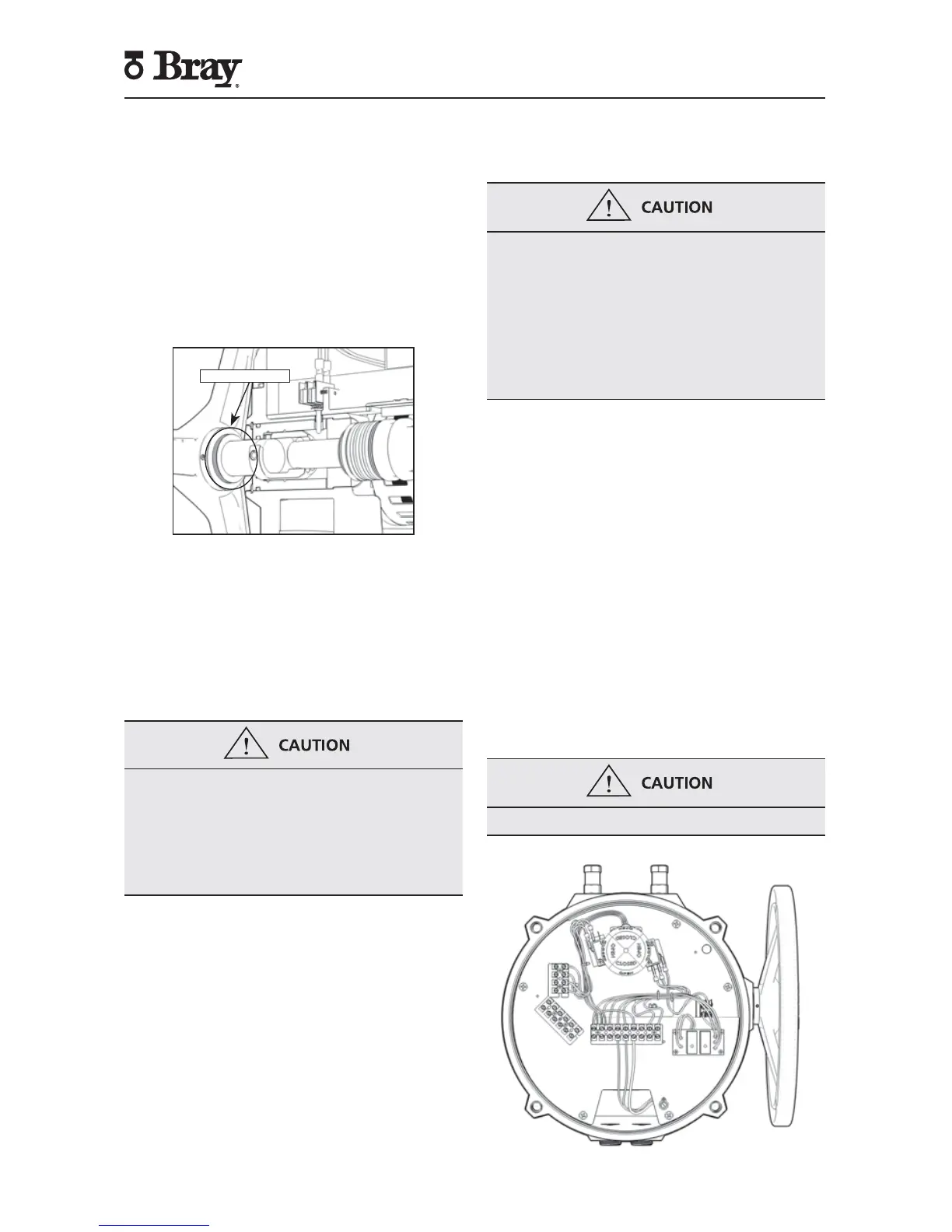

S70 On/Off Actuator with Interposing Relay

Board (I.R.B.)

The back feeding of one actuator by another one

wired in parallel is eliminated by using the I.R.B. If

actuator is running Open and customer switches

“instantaneously” to run Closed, the Open relay will

take time to ‘drop-out’ and the Close relay will take

time to ‘pull-in’ this time lapse is ~ 40ms. The time

delay provided by the I.R.B. will protect the switches

and gears from the controller’s instantaneous command

signal reversal. Current draws and field wirings are not

affected by adding I.R.B.

S70 120VAC I.R.B., auxiliary switch, heater, and torque

switch option are UL certified units

NOTE: The host controller should use a one second

time delay for command signal reversal.

Apply voltage to only one direction terminal at a time.

Figure 2 - S70 with I.R.B.

Loading...

Loading...