20

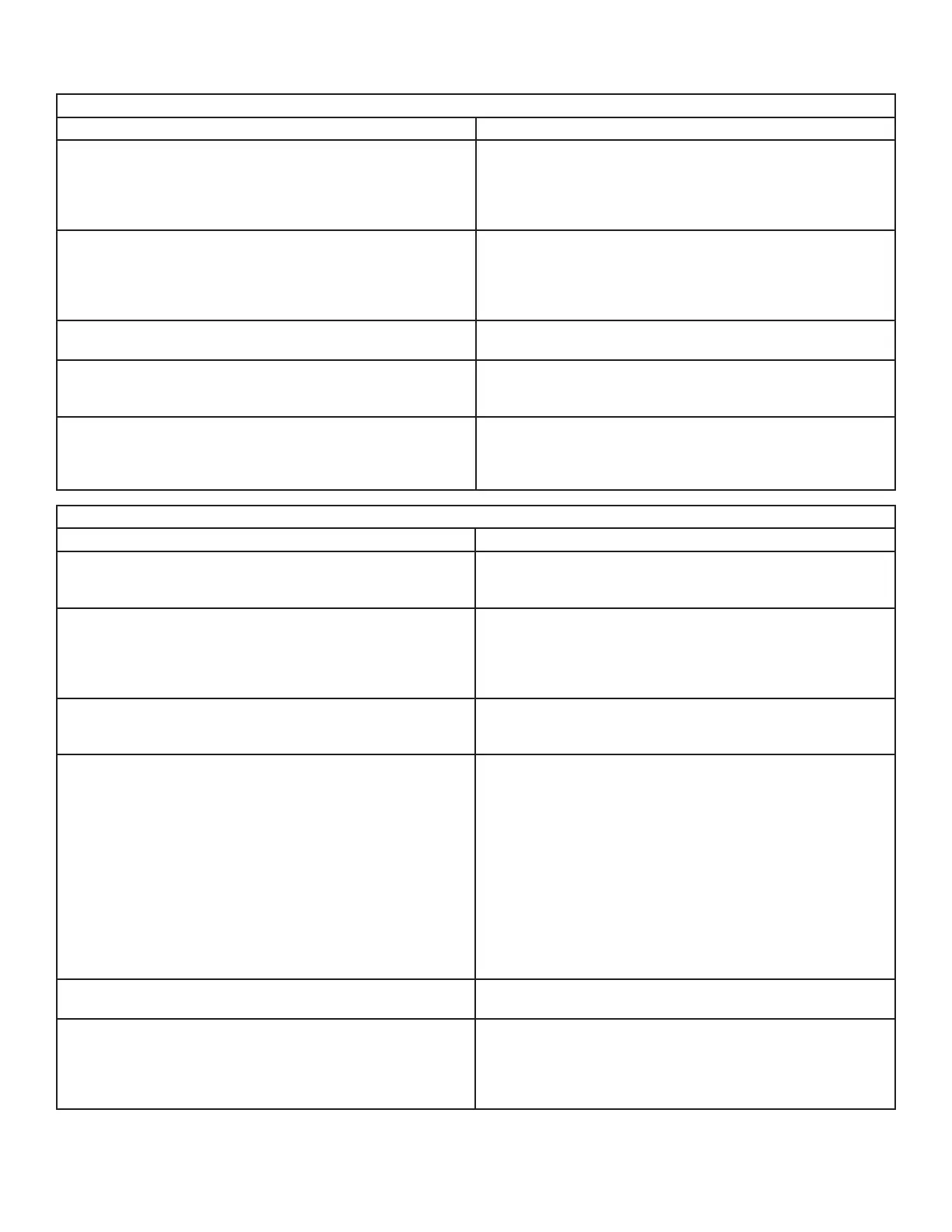

STOVE FEEDS PELLETS, BUT WILL NOT IGNITE

Possible Causes: Possible Remedies:

1. Air damper open too far for ignition.

Push the air damper in closer to the side of the stove for

startup. In some situations, it may be necessary to have the

damper completely closed for ignition to take place. After

there is a ame, the damper can then be adjusted for the

desired feed setting.

2. Blockage in igniter tube or inlet for igniter tube.

Find the igniter housing on the backside of the rewall. The

air intake hole is a small hole located on the bottom side of

the housing. Make sure it is clear. Also, look from the front of

the stove to make sure there is not any debris around the

igniter element inside of the igniter housing.

3. The burnpot is not pushed completely to the rear of the

rebox.

Make sure that the air intake collar on the burnpot is

touching the rear wall of the rebox.

4. Bad igniter element.

Put power directly to the igniter element. Watch the tip of

the igniter from the front of the stove. After about 2 minutes,

the tip should glow. If it does not, the element is bad.

5. The control board is not sending power to the igniter.

Check the voltage going to the igniter during startup. It

should be a full current. If the voltage is lower than full

current, check the wiring. If the wiring checks out good, the

board is bad.

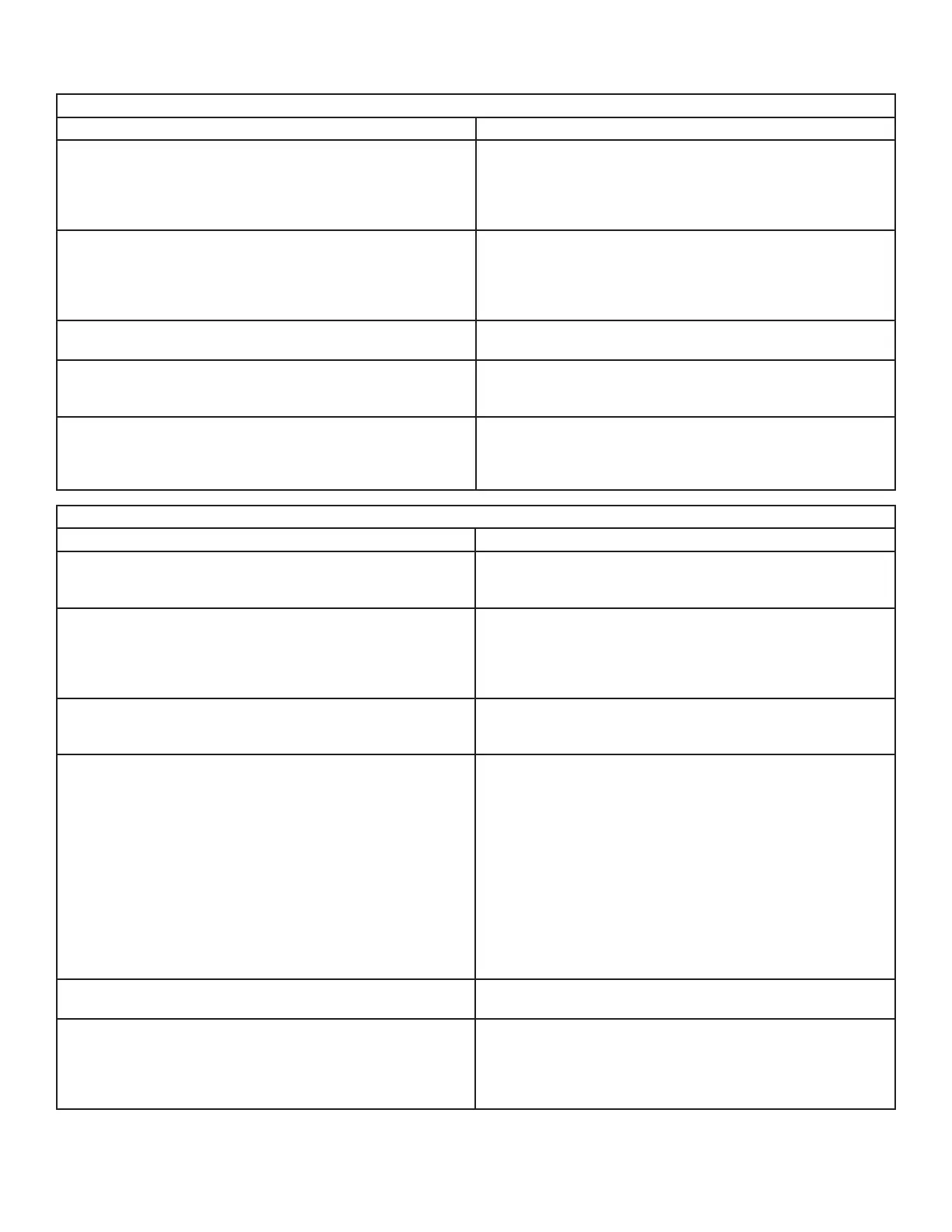

STOVE WILL NOT FEED PELLETS, BUT FUEL FEED LIGHT COMES ON AS DESIGNED

Possible Causes: Possible Remedies:

1. Fuse on control board blew.

Remove the control board. On the back, there is one fuse. If

it appears to be bad, replace it with a 5 Amp 125 Volt fuse.

Plug the stove back in and try to run the unit.

2. High limit switch has tripped or is defective.

Wait for the stove to cool for about 30-45 minutes. It should

now function normally. If not, use the owner’s manual to

locate the high limit thermodisc. To test if the thermodisc is

bad, you can bypass it as described previously for the POF

thermodisc.

3. Bad auger motor.

Remove the auger motor from the auger shaft and try to

run the unit. If the motor will turn, the shaft is jammed on

something. If the motor will not turn, the motor is bad.

4. Auger jam

Start by emptying the hopper. Then remove the auger

motor by removing the auger pin. Remove the auger shaft

inspection plate in the hopper so that you see the auger

shaft. Gently lift the auger shaft straight up so that the

end of the auger shaft comes up out of the bottom auger

bushing. Next, remove the two nuts that hold the top auger

biscuit in. Then rotate the bottom end of the auger shaft up

towards you until you can lift the shaft out of the stove. After

you have removed the shaft, inspect it for bent ights, burrs,

or broken welds. Remove any foreign material that might

have caused the jam. Also, check the auger tube for signs

of damage such as burrs, rough spots, or grooves cut into

the metal that could have caused a jam.

5. Loose wire or connector

Check all wires and connectors that connect to the auger

motor, high limit switch, and the Molex connector.

6. Bad control board

If the fuse is good, the wires and connectors check out

good, and the high limit switch did not trip, test r power

going to the auger motor. If there is not a full current going

to the auger motor when the fuel feed light is on, you have

a bad control board.

Troubleshooting Guide

Loading...

Loading...