2-21

SHEAVE BLOCK AND DOWNHAUL WEIGHT

The capacity chart shows the approved hoist rope arrangements. The downhaul weight

and sheave blocks supplied by Broderson are specially designed to operate the Anti-

Two-Block system. Other blocks or downhauls may bypass this system and create a

dangerous condition. Notice the load limit for each hoist rope arrangement.

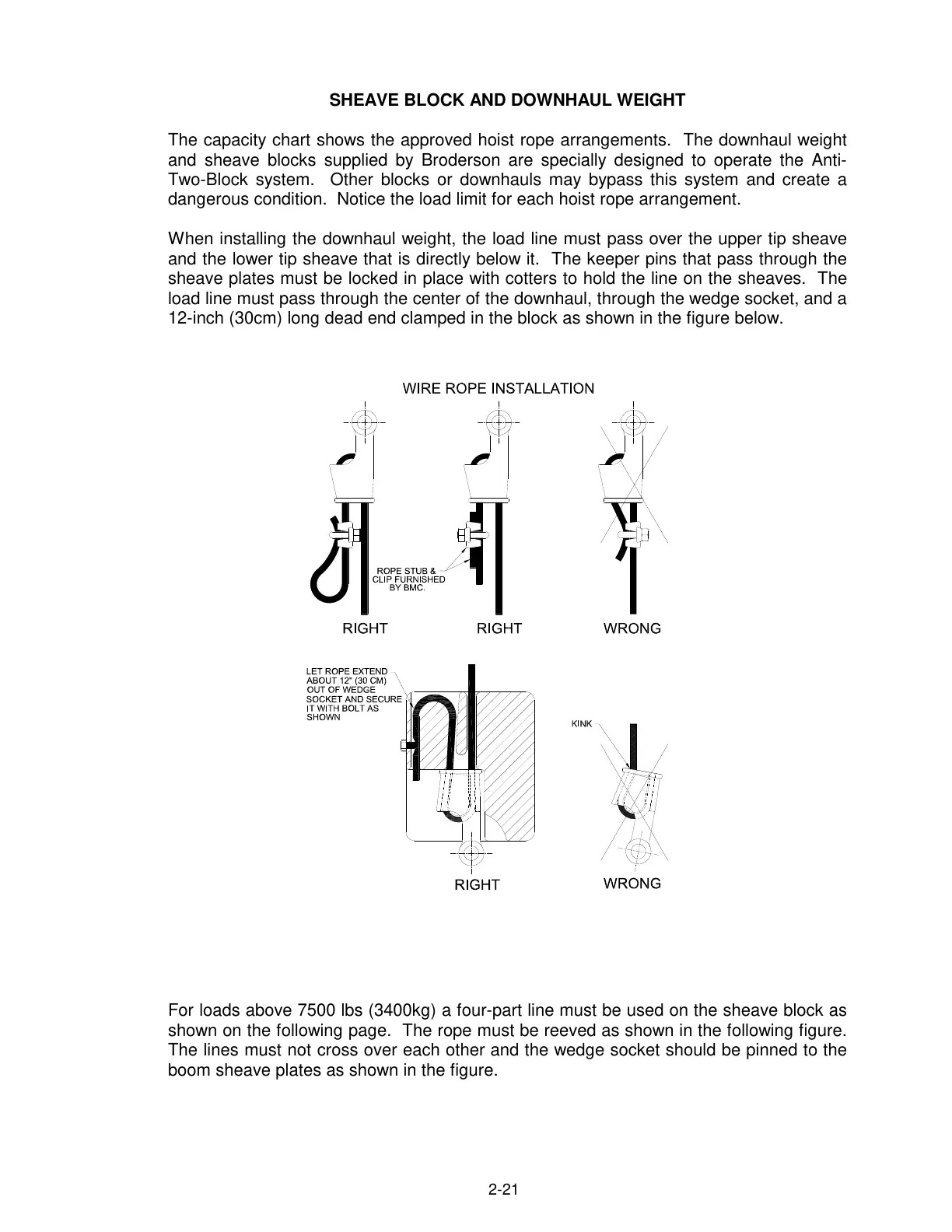

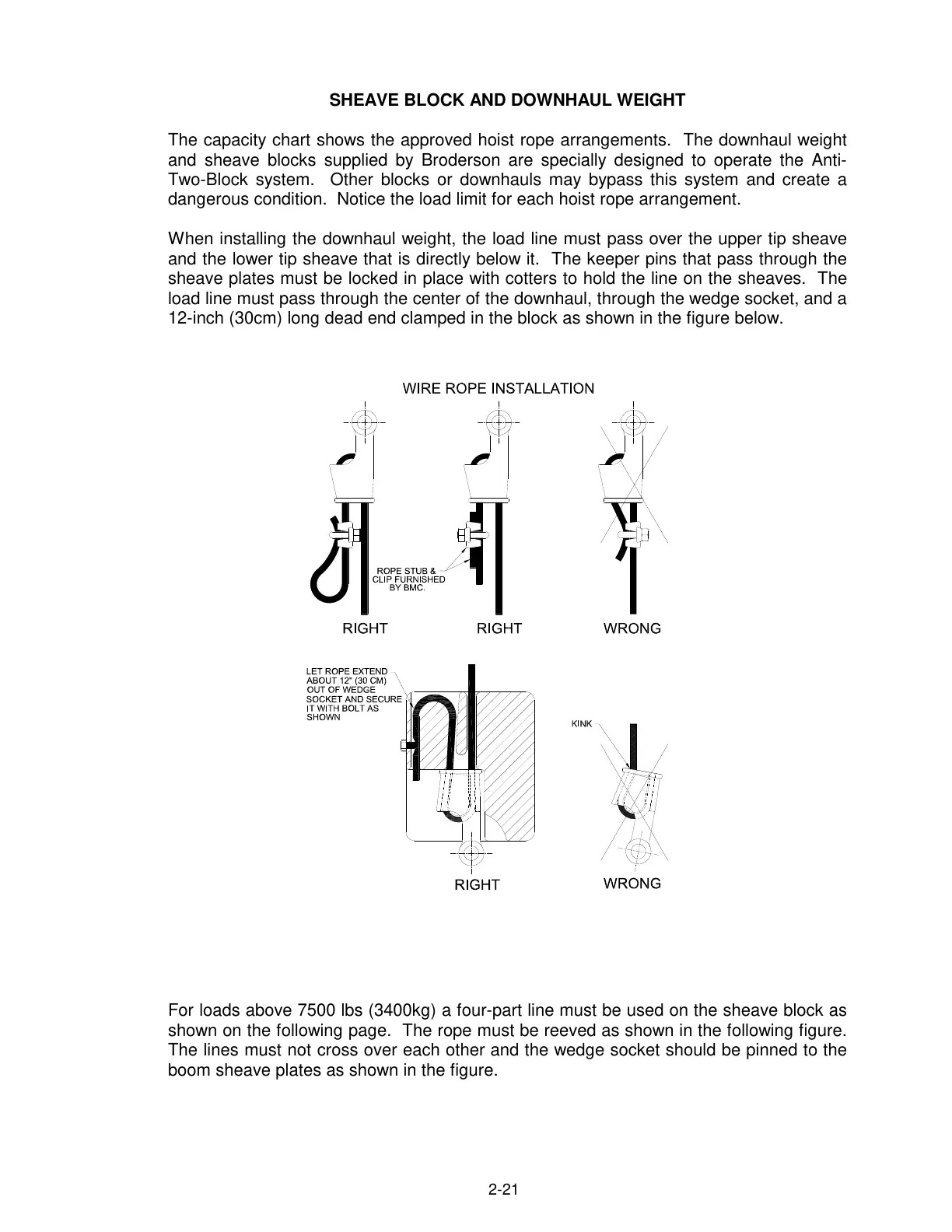

When installing the downhaul weight, the load line must pass over the upper tip sheave

and the lower tip sheave that is directly below it. The keeper pins that pass through the

sheave plates must be locked in place with cotters to hold the line on the sheaves. The

load line must pass through the center of the downhaul, through the wedge socket, and a

12-inch (30cm) long dead end clamped in the block as shown in the figure below.

For loads above 7500 lbs (3400kg) a four-part line must be used on the sheave block as

shown on the following page. The rope must be reeved as shown in the following figure.

The lines must not cross over each other and the wedge socket should be pinned to the

boom sheave plates as shown in the figure.

Courtesy of Crane.Market

Loading...

Loading...