OPERATION

HYDRAULIC SYSTEM.

IMPORTANT

To maintain maximum cooling of the hydraulic oil,

sod pieces must not be piled on the front tractor

weights. If more weight is required on the front of

the machine, loaded front tires can be used, or a

weight kit can be ordered from your dealer.

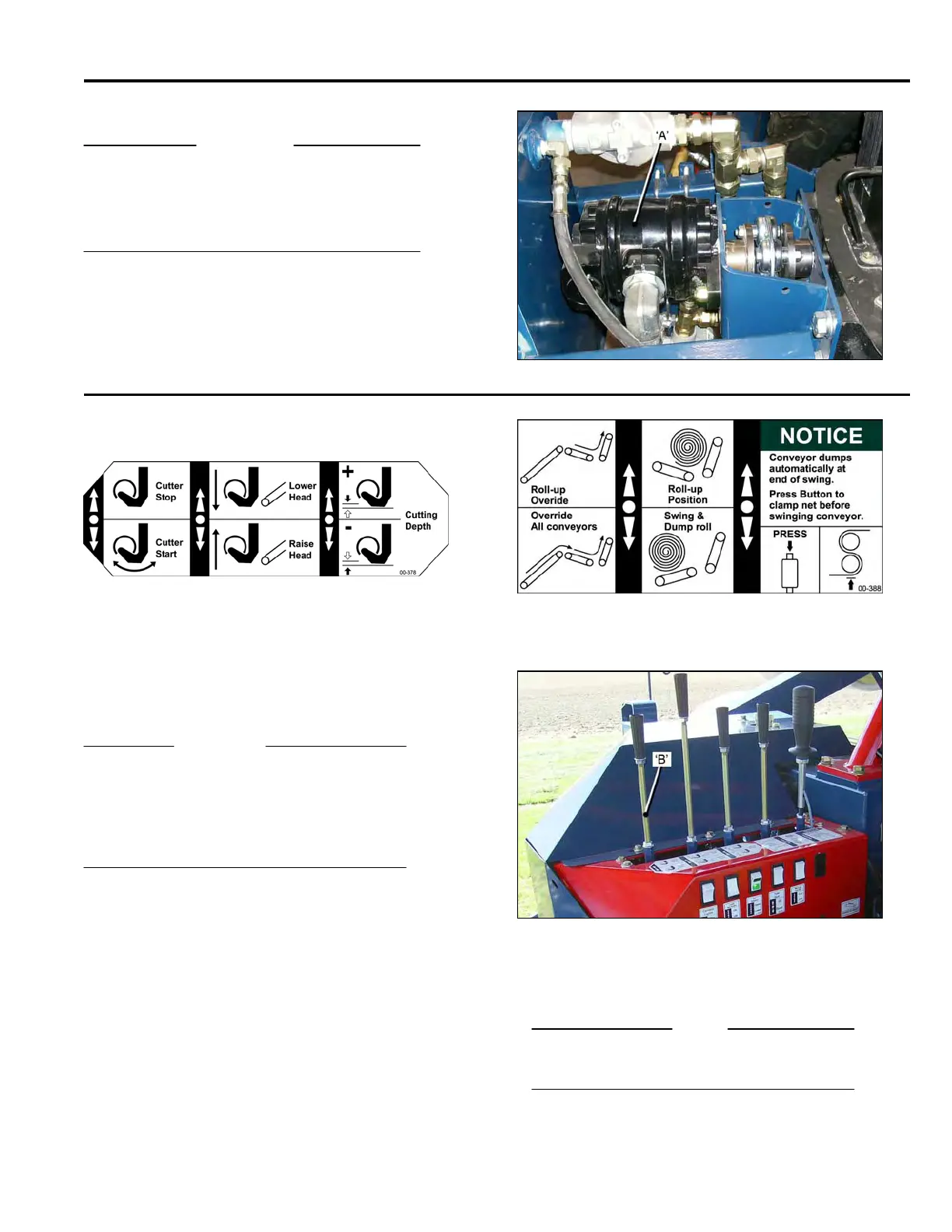

The RollMax Hydraulic System Pump ‘A’, is driven

from the front of the engine. It provides independent

oil supply to the Conveyor Drive, Cutter Drive and the

Roll Max Unit.

This allows for optimum speed from each motor.

CONTROLS.

Control Decals.

Cutter Engage, Lift Arm and Depth Control Levers.

CUTTER ‘ENGAGE’ CONTROL.

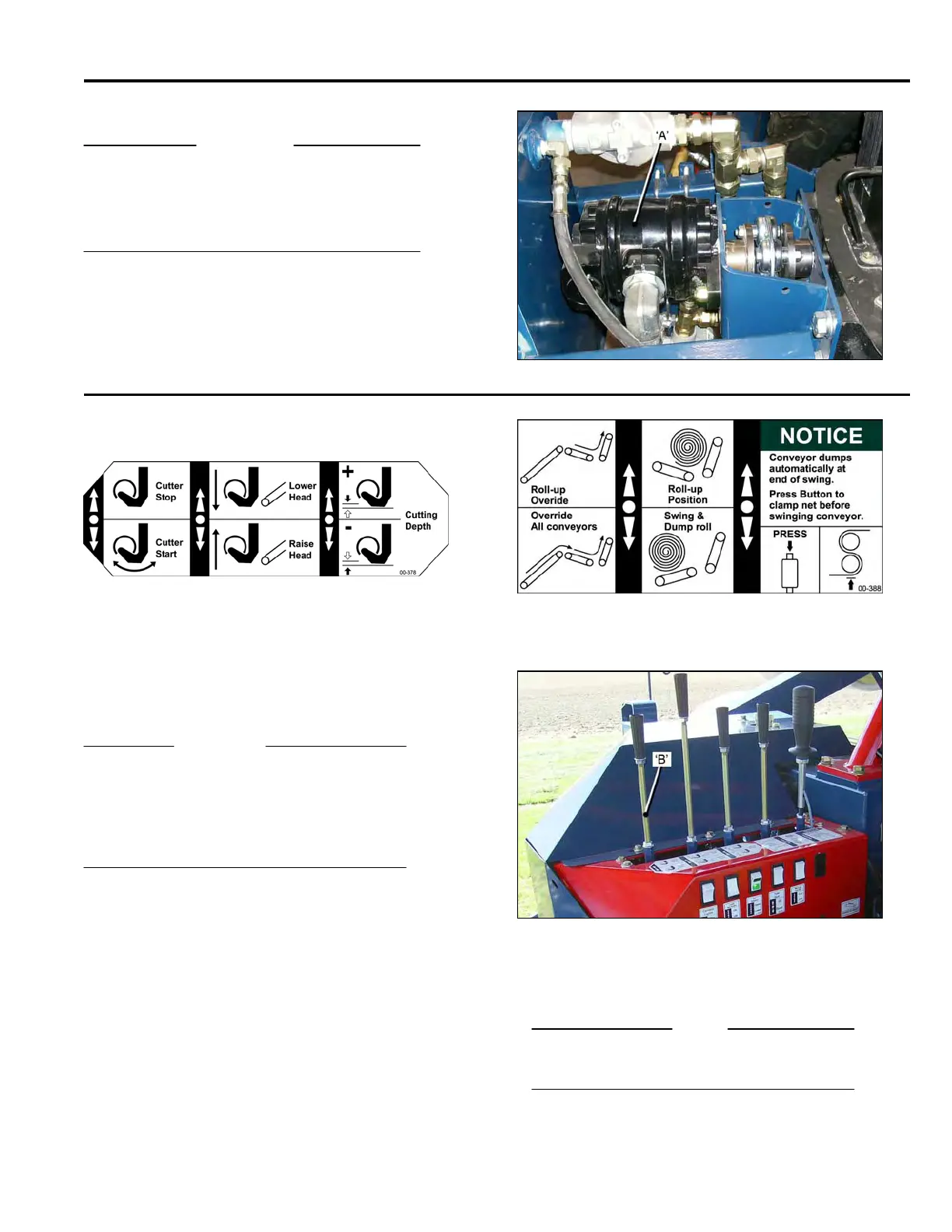

The Cutter Control Lever ‘B’.

• PULL – to start Cutter. (Detent).

• PUSH – to disengage Cutter.

CAUTION

To prevent damage to the Drive Line :

Do not engage the Cutter when traveling at over

2 mph. Damage to the Shear Pin on the Metering

Valve Input Shaft will occur. This will result in loss

of oil flow, indicating excessive ground speed or

malfunction of the front Flow Control Valve.

When the Cutter is engaged, the ground speed

control of the conveyor also engages.

The Conveyors will start automatically when the

machine moves ‘forward’, and will adjust speed to

match the ground speed.

If you have cut to the end of the field, and have a

partial roll, and wish to complete the roll on the next

pass, disengage the Cutter, this will stop the Cutter,

until cutting is re-started.

Conveyor Override, Roll-up Conveyor and Swing

Control Levers.

Also if it is necessary to ’skip over’ a section of

damaged or diseased turf, raise the Cutter Head to stop

the Cutter until resuming cutting by lowering the Cutter

Head.

NOTE

If the ‘Manual Cut-Off’ is engaged, the length of

Roll will automatically be re-set to ‘Start of Roll’.

3-03

Loading...

Loading...