ADJUSTMENTS

CONVEYOR MAT SLIDERS.

The Mat Sliders are made from UHMW Polyethylene,

and do not require lubrication or maintenance.

They have excellent service life, but should be checked

periodically for wear, particularly at the top and bottom

ends of the conveyor. Badly worn Sliders will result in

damage to the mat.

The over-all thickness of the Sliders is not the wear thick-

ness. The ‘T’ Bolt slot reduces the thickness to 3/8 inch.

To replace the Sliders:

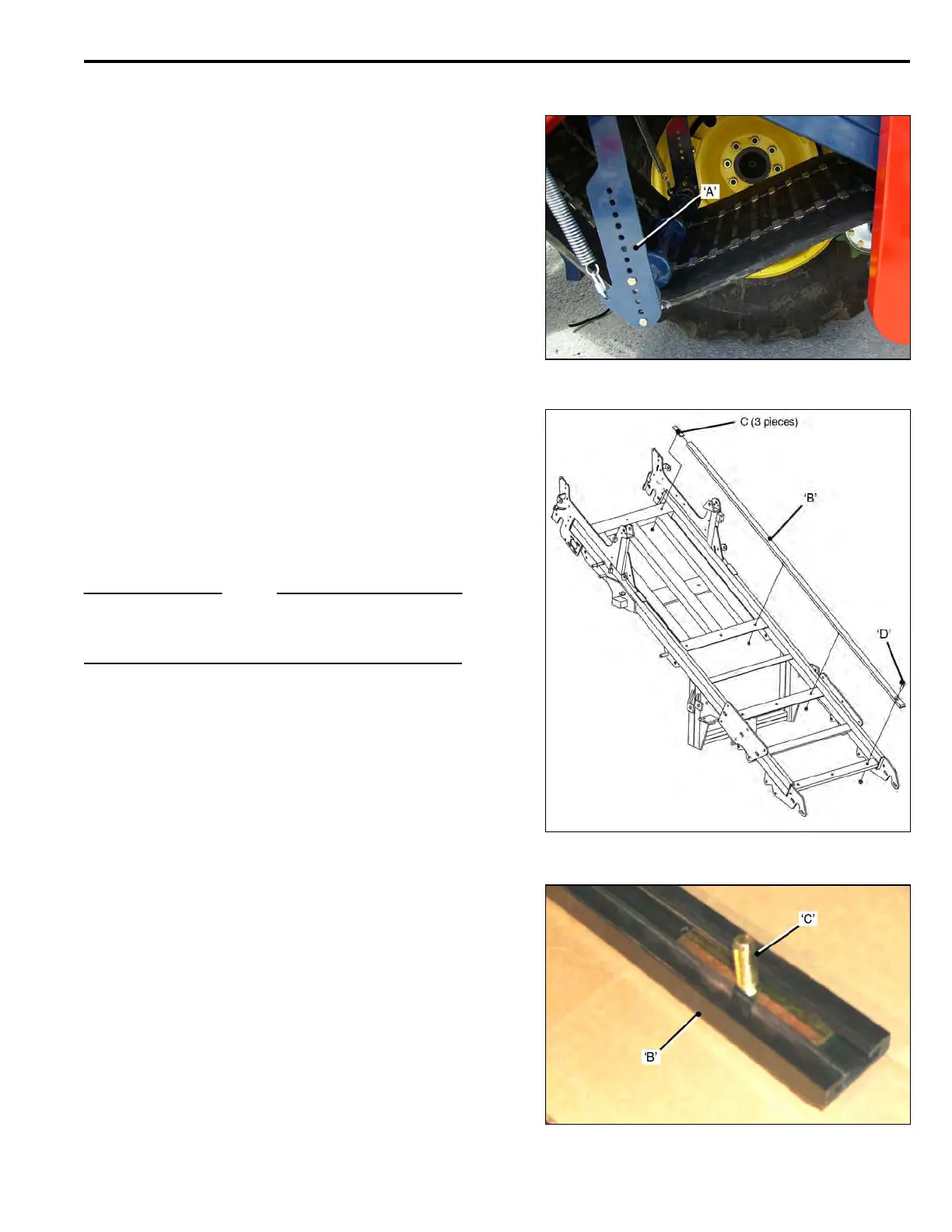

• Release the Mat Tension Idler ‘A’.

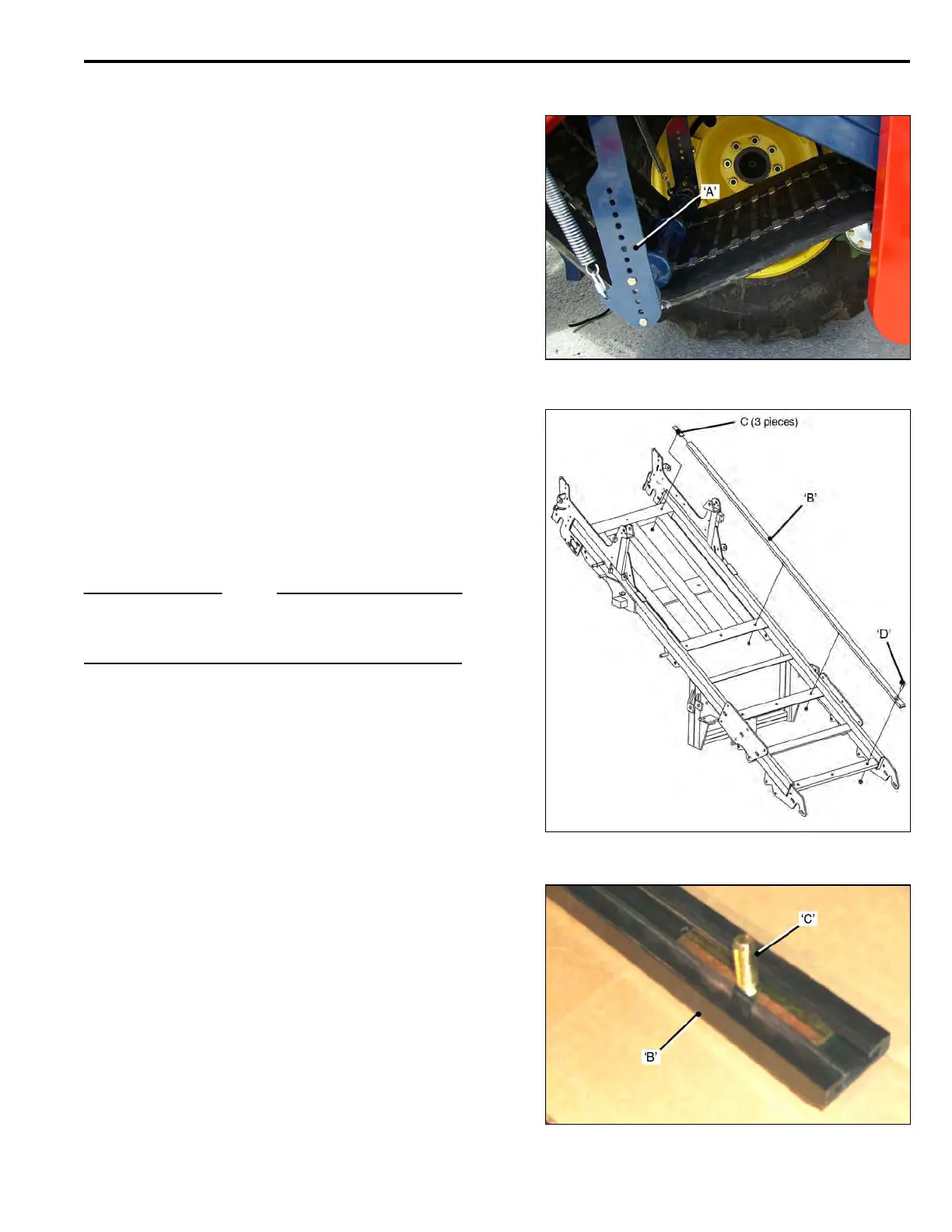

• Raise and support the Mat, as high as possible,

clear of the Sliders ‘B’.

• Remove the Locknuts from the ‘T’ Bolts ‘C’,

and Socket Cap Screws ‘D’, that fasten the

Sliders to the Conveyor Frame, and lift the Sliders

out of the Frame.

• Fit three ‘T’ Bolts into each new Slider, and install

them onto the Conveyor Frame. Fit the Socket

Cap Screws.

• Fit the Locknuts. Tighten them until they are

just ‘snug’. This will allow the Sliders to shrink or

expand with changes in temperature or humidity.

If they are too tight the Sliders may ‘buckle’.

NOTE

The 24 inch Conveyor has three Sliders. To prevent the

possibility of ‘tapered’ rolls it is recommended that they

are replaced as a set.

3-17

Loading...

Loading...