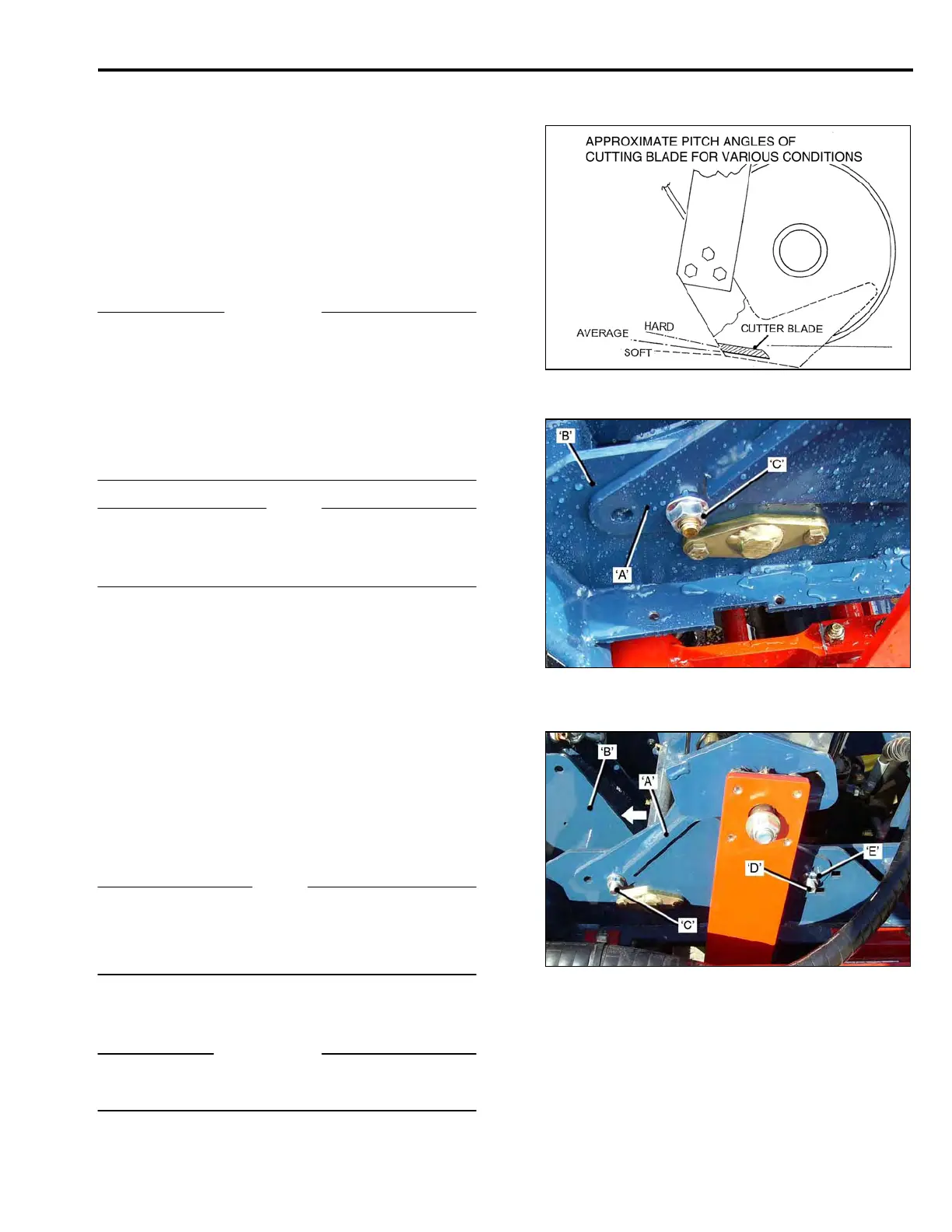

PITCH ANGLE SETTING.

Pitch Angle is the angle that the Cutter Blade makes

relative to the ground. The Pitch Angle is set at the

factory for average conditions. It can be adjusted to

improve cutting performance in hard or soft soils.

In soft conditions the Pitch Angle should be set so that

the cutting blade is almost ‘parallel’ to the Ground.

In harder conditions the angle should be increased,

this maintains the cutting angle and also prevents the

Cutting Head from coming out of the ground.

IMPORTANT

When the Pitch Angle is changed, the relationship of

the Cutting Blade to the Conveyor Mat and also the

Ground Roller, must be maintained.

The front Idler Shaft of the Conveyor can be adjusted

to ensure that there is no interference between the mat

and the blade.

Refer to the Ground Roller adjustment instructions for

correct Roller to Blade set-up.

NOTE

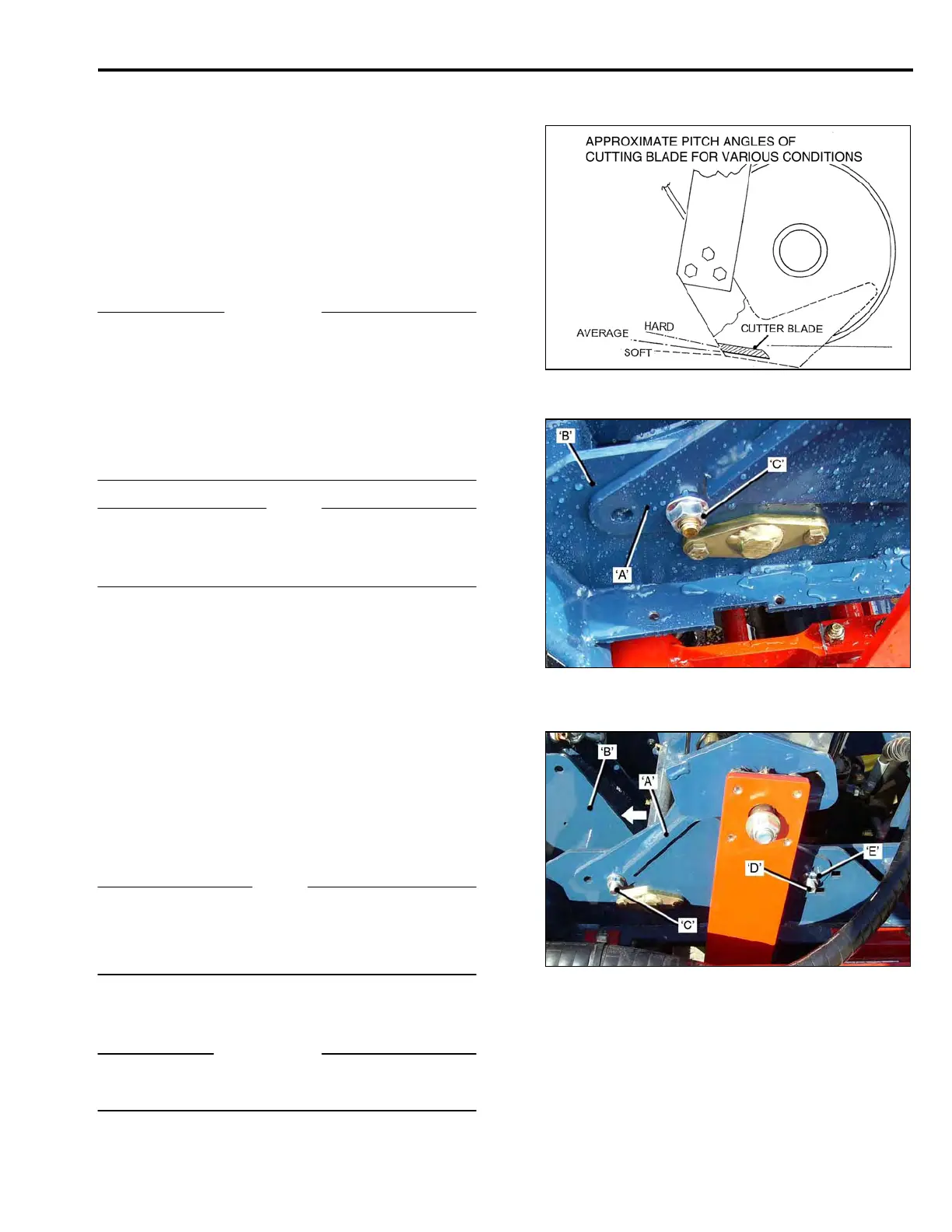

The factory setting for the pitch angle locates the Adj-

uster Bracket ‘A’, in the second hole from the rear, in

the Cutter Head Frame ‘B’.

To adjust the Pitch Angle:

• Loosen the Nuts ‘C’, sufficient to allow the

Adjuster Bracket to slide in the Cutter Head

Frame.

• Remove Locator Bolts ‘D’. (See Note below).

• For soft soil or peat, pull the Adjuster Bracket

‘BACK’, in the direction of arrow, and refit the

Locator Bolts in the first hole to the rear in

the Cutter Frame.

• For harder soils, locate the Adjuster Frame in

the third or fourth holes, to the front of the

Cutter Head Frame.

• Fully tighten all fasteners.

NOTE

The Locator Bolts are fitted in the ‘center holes’ in the

Adjuster Bracket ‘C’. The ‘upper’ and ‘lower’ holes ‘E’,

are for depth of cut adjustment. See following pages for

depth adjustment.

IMPORTANT

Check the fasteners regularly for tightness to ensure

that they do not loosen during operation.

ADJUSTMENTS

3-11

Loading...

Loading...