926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

52

FURNACE CONTROL PROGRAMMING

AND NAVIGATION

On-Board Control Method

This furnace model is equipped with an on-board 3-digit LCD display

with pushbutton navigation for the adjustment of operating parameters,

diagnostics, and service. The control board must be powered to use the

display and pushbuttons. Upon startup, the control will alternate

displaying the Model Program Number (PRG) and Software Version

(uEr). The control board has been programmed at the factory with a

Model Program Number specific to the furnace product number. The

correct Model Program Number is shown on the furnace rating plate.

The system’s status is displayed after startup or after no control buttons

have been pressed for 60 seconds. Status Code LED will also be

illuminated or blinking when displaying the system status. The codes

which indicate the current operating mode of the system as shown in

Table 21.

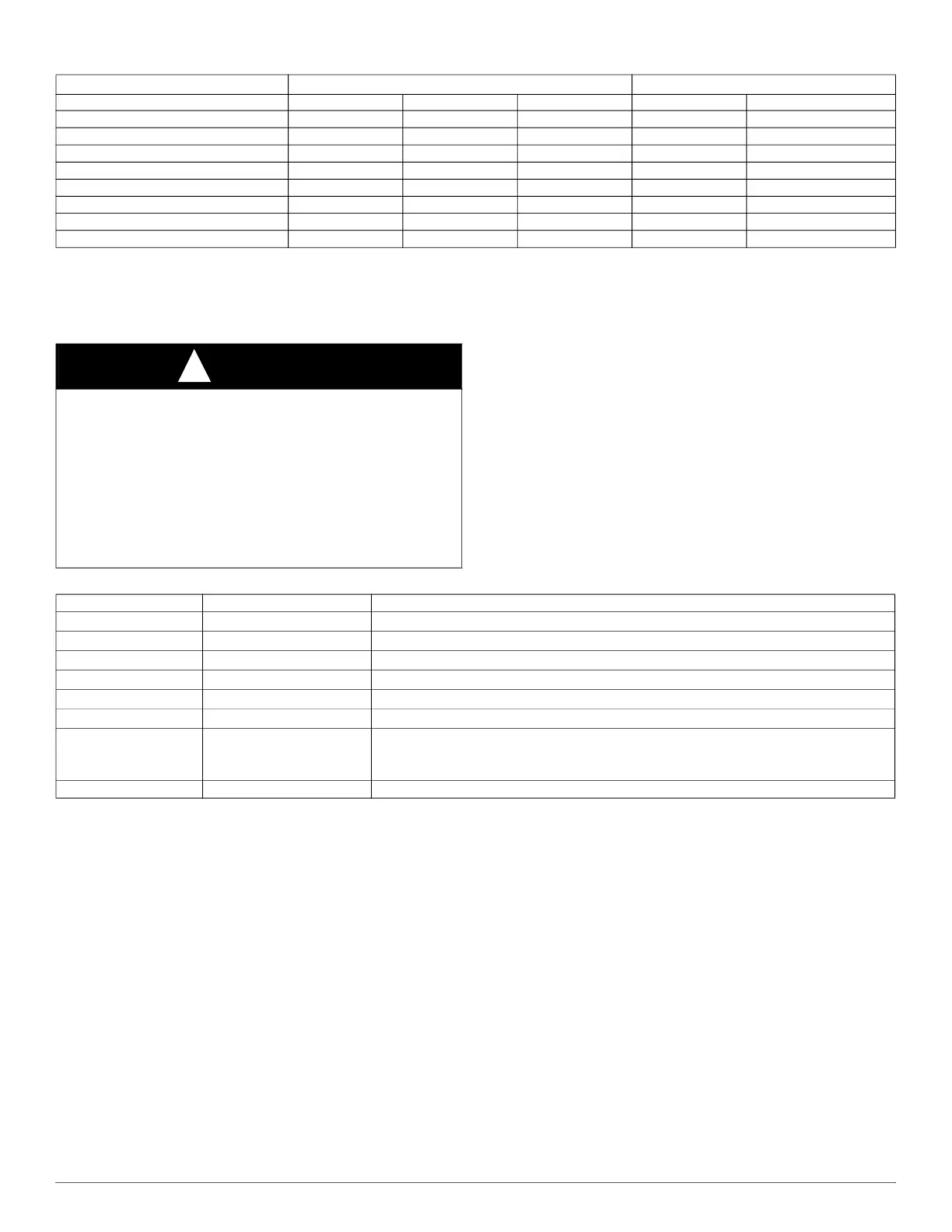

Table 20 – Default Airflow Settings

Default Airflow Settings

*

*. Setting #1 is the default setting for Constant Fan

Designated Airflow Settings

Unit Size Heating High Cooling Low Cooling Heating Const. Fan

30040V14 13 25 17 (9 - 15) (1 - 3)

36040V17 9 24 13 (5 - 10) (1 - 3)

36060V14 15 25 15 (10 - 15) (1 - 3)

48060V17 10 25 13 (6 - 11) (1 - 8)

48080V17 15 24 14 (9 - 16) (1 - 3)

60080V21 9 25 14 (6 - 12) (1 - 8)

60100V21 13 24 12 (10 - 14) (1 - 6)

66120V24 17 22 12 (12 - 17) (1 - 3)

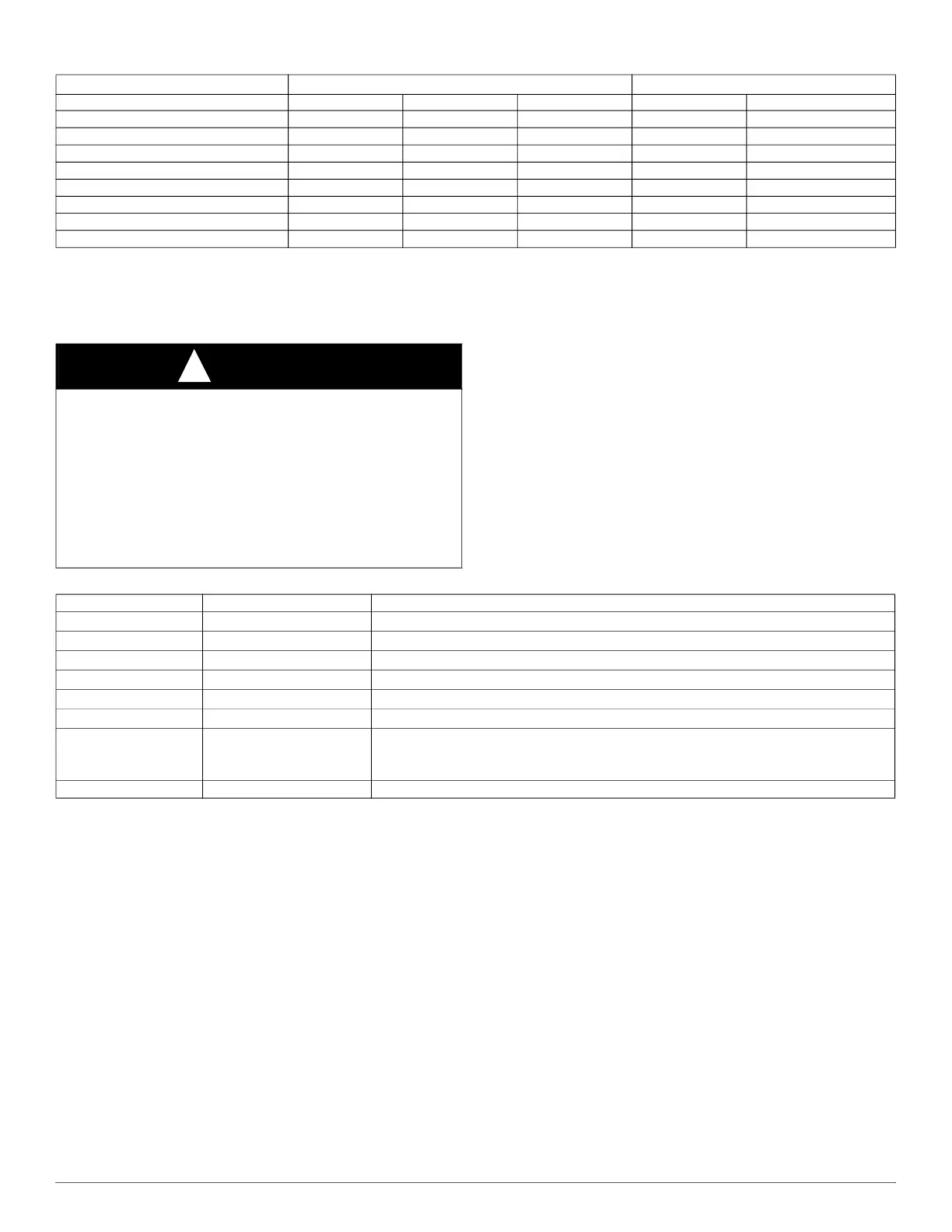

CAUTION

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury, or death.

Blower access door switch removes 115-V power to control. No

component operation can occur unless switch is closed. Caution must

be taken when manually closing this switch for service purposes.

Do not tape or permanently allow the door switch to be bypassed.

Temporarily depress the door switch with one hand while accessing the

service buttons with your other hand. Do not touch uninsulated

electrical components.

Table 21 – System Status Display Codes

Display Operating Mode Notes:

iDl

Idle/Standby Mode No active demands

Ht

Heating Mode Gas Heating active

CL2

High Cooling Mode Cooling or Heat Pump active

CL1

Low Cooling Mode Cooling or Heat Pump active

Hpd

Heat Pump Defrost Mode Gas Heating cycle active during Heat Pump Defrost cycle

Cfn, CF2, CF3

Continuous Fan Mode Continuous Fan active

bLr

Secondary Unit Operating

Blower during

Cfn, CL, or

Ht

Only used when control is the secondary furnace of a twinned furnace system and primary

furnace is active

##.# Active Status Code See Fig. 60 or Furnace Service Label for codes

Loading...

Loading...