926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

6

The furnace should be sized to provide 100 percent of the design heating

load requirement plus any margin that occurs because of furnace model

size capacity increments. None of the furnace model sizes can be used if

the heating load is 20,000 BTU or lower. Use Air Conditioning

Contractors of America (Manual J and S); American Society of Heating,

Refrigerating, and Air-Conditioning Engineers; or other approved

engineering method to calculate heating load estimates and select the

furnace. Excessive oversizing of the furnace may cause the furnace

and/or vent to fail prematurely, customer discomfort and/or vent

freezing.

Failure to follow these guidelines is considered faulty installation and/or

misapplication of the furnace; and resulting failure, damage, or repairs

may impact warranty coverage.

For accessory installation details, refer to the applicable instruction

literature.

NOTE: Remove all shipping materials, loose parts bag, and literature

before operating the furnace. See Table 3.

Table 3 – Loose Parts Bag

NOTE: The 40K models are the only furnaces that receive the outlet

restrictor in loose parts bag. See Maximum Equivalent Vent Length

Table for usage.

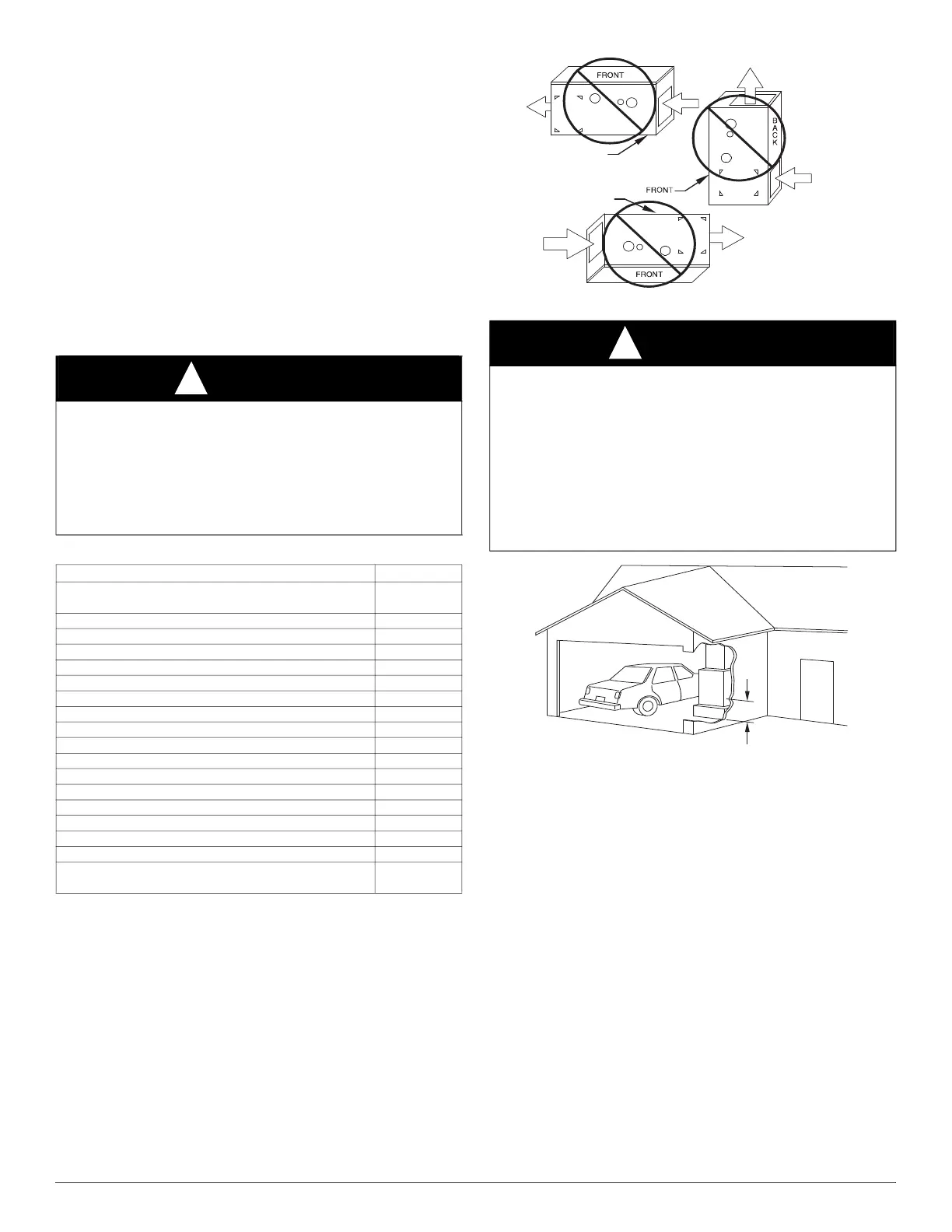

A12182

Fig. 4 – Prohibited Installations

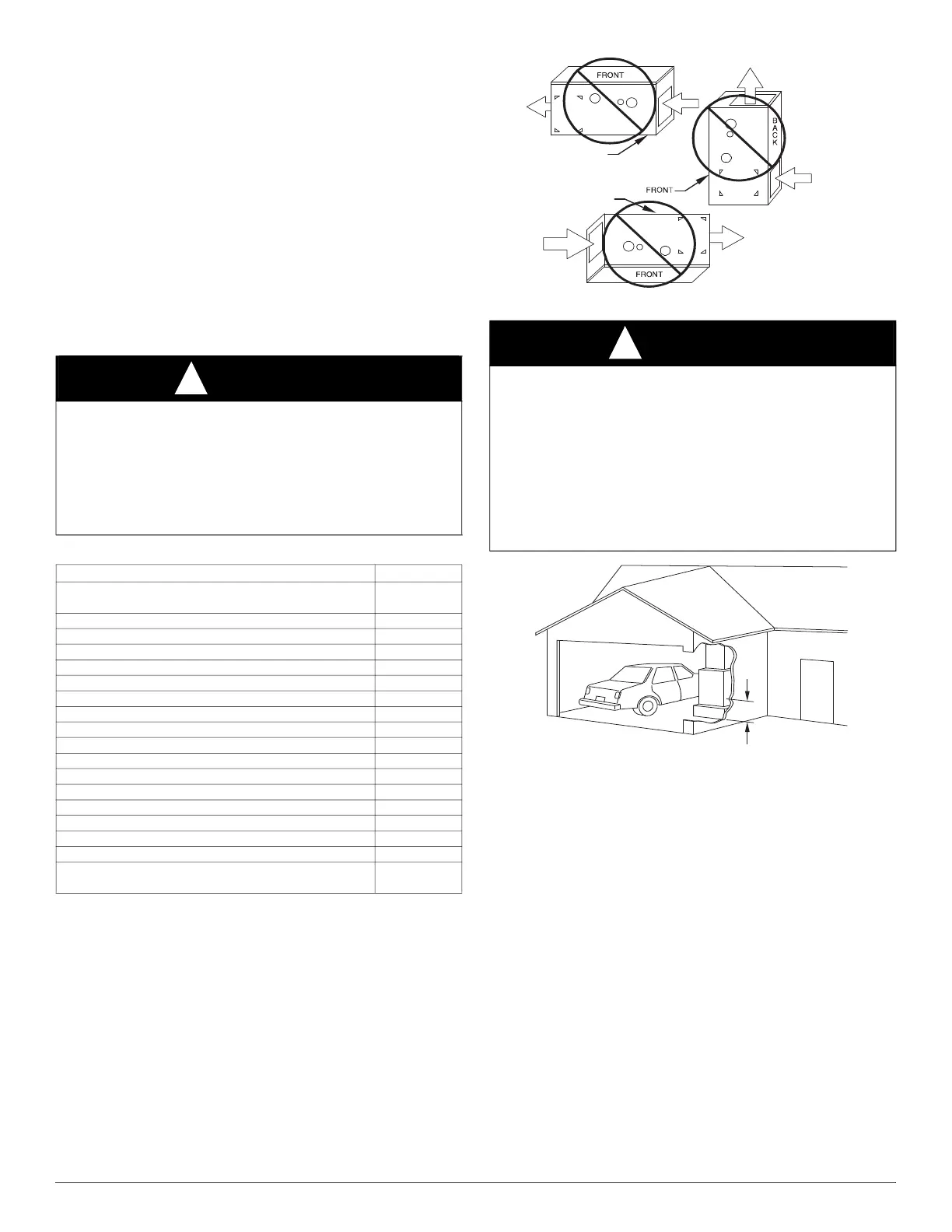

A93044

Fig. 5 – Installation in a Garage

CODES AND STANDARDS

Follow all national and local codes and standards in addition to these

instructions. The installation must comply with regulations of the

serving gas supplier, local building, heating, plumbing, and other codes.

In absence of local codes, the installation must comply with the national

codes listed below and all authorities having jurisdiction.

In the United States and Canada, follow all codes and standards for the

following:

Safety

• US: Current edition of National Fuel Gas Code NFPA 54/ANSI

Z223.1 and the Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B

• CANADA: Current edition of National Standard of Canada, Natural

Gas and Propane Installation Code (NSCNGPIC) CAN/CSA B149.1

General Installation

• US: NFPA 54/ANSI Z223.1 and the NFPA 90B. For copies, contact

the National Fire Protection Association Inc., Batterymarch Park,

Quincy, MA 02269; or for only the NFPA 54/ANSI Z223.1 contact the

WARNING

!

FIRE HAZARD

Failure to follow this warning could result in personal injury, death

and/or property damage.

Do not install the furnace on its back or hang furnace with control

compartment facing downward. Safety control operation will be

adversely affected. Never connect return-air ducts to the back of the

furnace. See Fig. 4.

DESCRIPTION QUANTITY

Outlet Restrictor Plate (provided with 40K BTUh

furnaces only; see Note)

1

Air Intake Pipe Flange 1

Vent Pipe Flange 1

Pipe Flange Gaskets 2

Sharp Tip Screws (Vent and Inlet Flanges) 10

Vent Pipe Coupling 1

Vent Pipe Coupling Clamps 2

Pressure Switch Tube 1

Rubber Drain Elbow 1

Drain Tube Clamps 4

1/2-in. CPVC to 3/4-in. PVC Pipe Adapter 1

Gas Line Grommet 1

Junction Box Cover 1

Junction Box Base 1

Green Ground Screw 1

Blunt Tip Screws (Junction Box) 3

Thermostat Wire Grommet 1

Drain Extension Tube (Z-pipe) (Provided separately in

furnace)

1

WARNING

!

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal injury, death

and/or property damage.

When the furnace is installed in a residential garage, the burners and

burner ignition devices must be located at least 18 in. (457 mm) above

the floor. The furnace must be located or protected to avoid damage by

vehicles. When the furnace is installed in a public garage, airplane

hangar, or other building having a hazardous atmosphere, the furnace

must be installed in accordance with the current edition of NFPA

54/ANSI Z223.1 or CAN/CSA B149.2. See Fig. 5.

BACK POSITIONED

DOWNWARD

AIR RETURN

CUT IN BACK

BACK POSITIONED

UPWARD

18-IN. (457.2 mm)

MINIMUM TO BURNERS

Loading...

Loading...