926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

30

IPEX PVC qui sont certifiées à ce standard. Au Canada, l’apprêt et le

ciment doivent être du même fabricant que le système d’évacuation.

L’apprêt GVS-65 (Purple) et le ciment-solvant GVS-65 doivent être

utilisé avec les Royal Pipe. Système IPEX 636, apprêt PVC/CPVC,

Purple pour évacuation des gaz de combustion et système IPEX 636(1)t,

ciment PVC pour évacuation des gaz de combustion, coté classe IIA, 65

deg C. doivent être utilisés avec le système d’évacuation IPEX 636 – Ne

pas combiner l ’apprêt et le ciment d’un manufacturier avec un système

d’évacuation d’un manufacturier différent.

Bien suivre les indications du manufacturier lors de l’utilisation de

l’apprêt et du ciment et ne pas utiliser ceux-ci si la date d’expiration est

atteinte.

L’opération sécuritaire, tel que définit par ULC S636, du système de

ventilation est basé sur les instructions d’installation suivantes, ainsi que

l’usage approprié de lapprêt et ciment. Tout arrët feu et solin de toit

utilisés avec ce système doivent être des matériaux listés UL.

L’acceptation du standard Canadien CAN/CSA B149 est directement

relié à l’installation conforme aux instructions ci- haut mentionnées. Le

standard Canadien recommande l’inspection par un personel qualifié et

ce, une fois par année.

Les autoritées ayant juridiction (inspecteurs de gas, inspecteurs en

bâtiments, département des incendies, etc) devraient être consultées

avant l’installation afin de déterminer si un permis est requis.

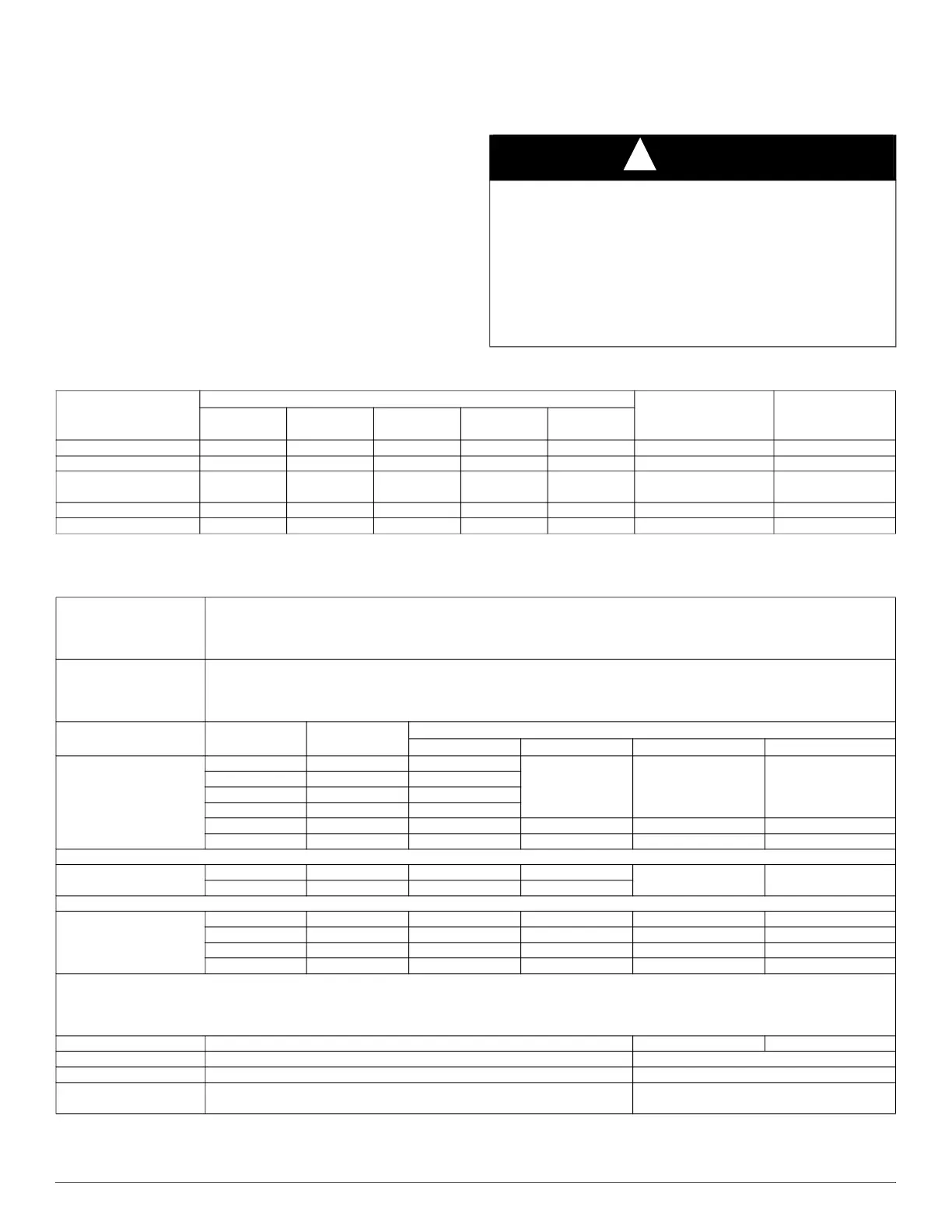

Table 13 – Vent Termination Kit for Direct Vent

(2-pipe) Systems

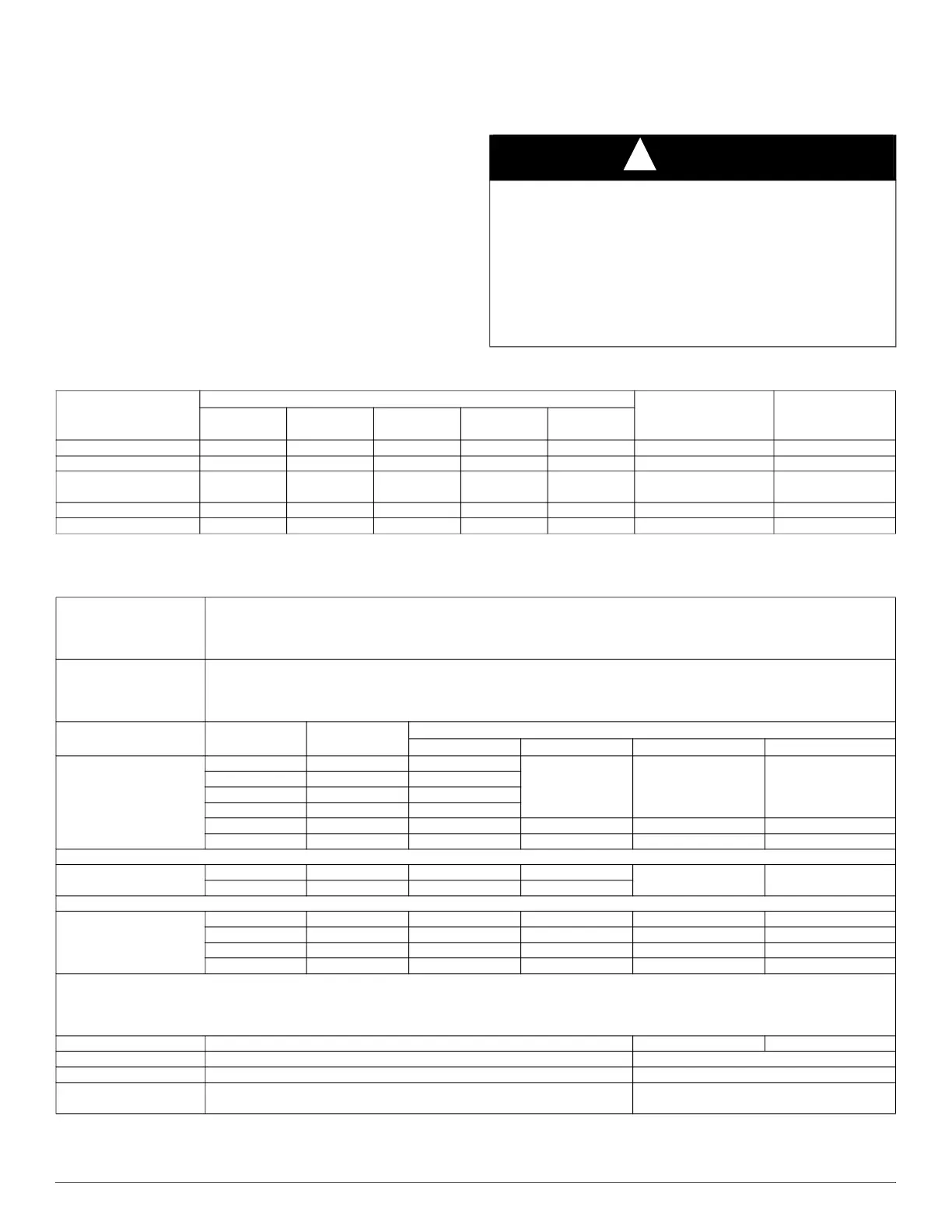

Table 14 – Approved Combustion-Air and Vent Pipe, Fitting

and Cement Materials

NOTICE

!

RECOMMENDED SUPPORT FOR VENT

TERMINATION

It is recommended that sidewall vent terminations of over 24 inches

(0.6 M) in length or rooftop vent terminations of over 36 inches (1 M)

in length be supported by EITHER the factory accessory vent

termination kit or field-supplied brackets or supports attached to the

structure. A factory accessory vent termination kit may be used for

direct vent terminations. Termination kits are available for 2-in. or 3-in.

pipe. See Table 13 for available options.

Vent and Combustion

Air Pipe Diameters

Approved Two-Pipe Termination Fittings

Allowable Concentric

Vent Kit

Concentric Vent

Kit

1 1/2-in.

(38 mm)

2-in.

(51 mm)

2 1/2-in.

(64 mm)

3-in.

(76-mm)

4-in.

(102 mm)

1 1/2-in. (38 mm) No Yes No No No 2-in. (51 mm) KGAVT0701CVT

2-in. (51 mm) No Yes No No No 2-in. (51 mm) KGAVT0701CVT

2 1/2-in. (64 mm) No No No Yes No

2-in. (51 mm)

3-in. (76 mm)

KGAVT0701CVT

KGAVT0801CVT

3-in. (76-mm) No No No Yes No 3-in. (76 mm) KGAVT0801CVT

4-in. (102 mm) No No No Yes Yes 3-in. (76 mm) KGAVT0801CVT

MATERIALS

USA

1. All pipe*, fittings*, primers**, and solvents** must conform to American National Standards Institute (ANSI) standards and

American Society for Testing and Materials (ASTM) standards

2. See Table below for approved materials for use in the U.S.A.

3. UL 1738 vent systems must be composed of pipe*, fittings**, cements, and primers** from the same supplier.

CANADA

1. Installation in Canada must conform to the requirements of CAN/CSA B149 code.

2. Vent systems must be composed of pipe*, fittings*, cements, and primers from the same supplier and listed to ULC S636.

3. Not all materials below may be approved or listed to ULC S636.

4. Factory accessory concentric vent kits are ULC S636 listed.

Material Description Type

ASTM / ULC / UL Specification

Pipe* Fittings* Solvents/Primers** Cements

PVC

Pressure Pipe Schedule 40 D1785 / UL 1738

D2466 or D2665 F656 D2564

DWV Schedule 40 D1785 / D2665

SDR 26 N/A D2241

SDR 21 N/A D2241

IPEX Schedule 40 ULC S636 ULC S636 ULC S636 ULC S636

Royal Pipe Schedule 40 ULC S636 ULC S636 ULC S636 ULC S636

ABS

ABS Schedule 40 D2661 D2468 Clear Cleaner For

ABS†

D2235

DWV-IPS Sizes Schedule 40 D2661 D2661

CPVC

Pressure Pipe Schedule 40 F441 F438 F656 F493

SDR N/A F442 N/A

IPEX Schedule 40 ULC S636 ULC S636 ULC S636 ULC S636

Royal Pipe Schedule 40 ULC S636 ULC S636 ULC S636 ULC S636

* PVC and ABS pipe may use either DWV or pressure rated fittings.

** Colored or tinted solvents or primers must be used where required by code in the USA

† ABS plastic does not require a primer before solvent cementing. A cleaner for ABS is recommended to remove any surface residue. ABS cleaners are

not subject to ASTM standards.

Polypropylene Approved Manufacturer Solvents Primers Cements

Poly Pro® M & G Dura Vent Not Permitted

Innoflue® Centrotherm Not Permitted

ECCO Polypropylene

Vent®

ECCO Manufacturing Not Permitted

NOTE: Polypropylene vent systems are UL−1738 and ULC S636 listed and assembled using mechanical fastening systems supplied by the vent

manufacturer.

Loading...

Loading...