926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

11

2. An attic or crawlspace may be considered a space that freely

communicates with the outdoors provided there are adequate

permanent ventilation openings directly to outdoors having free

area of at least 1-in.2/4,000 BTUh of total input rating for all gas

appliances in the space.

3. In spaces that use the Indoor Combustion Air Method, infiltration

should be adequate to provide air for combustion, permanent

ventilation and dilution of flue gases. However, in buildings with

unusually tight construction, additional air MUST be provided

using the methods described in the Outdoor Combustion Air

Method section.

4. Unusually tight construction is defined as Construction with:

a. Walls and ceilings exposed to the outdoors have a continuous,

sealed vapor barrier. Openings are gasketed or sealed and

b. Doors and openable windows are weatherstripped and

c. Other openings are caulked or sealed. These include joints

around window and door frames, between sole plates and floors,

between wall-ceiling joints, between wall panels, at penetrations

for plumbing, electrical and gas lines, etc.

Combination of Indoor and Outdoor Air

1. Indoor openings shall comply with the Indoor Combustion Air

Method below and,

2. Outdoor openings shall be located as required in the Outdoor

Combustion Air Method mentioned previously and,

3. Outdoor openings shall be sized as follows:

a. Calculate the Ratio of all Indoor Space volume divided by

required volume for Indoor Combustion Air Method below.

b. Outdoor opening size reduction Factor is 1 minus the Ratio in a.

above.

c. Minimum size of Outdoor openings shall be the size required in

Outdoor Combustion Air Method above multiplied by reduction

Factor in b. above. The minimum dimension of air openings shall

be not less than 3 in. (80 mm).

CONDENSATE TRAP

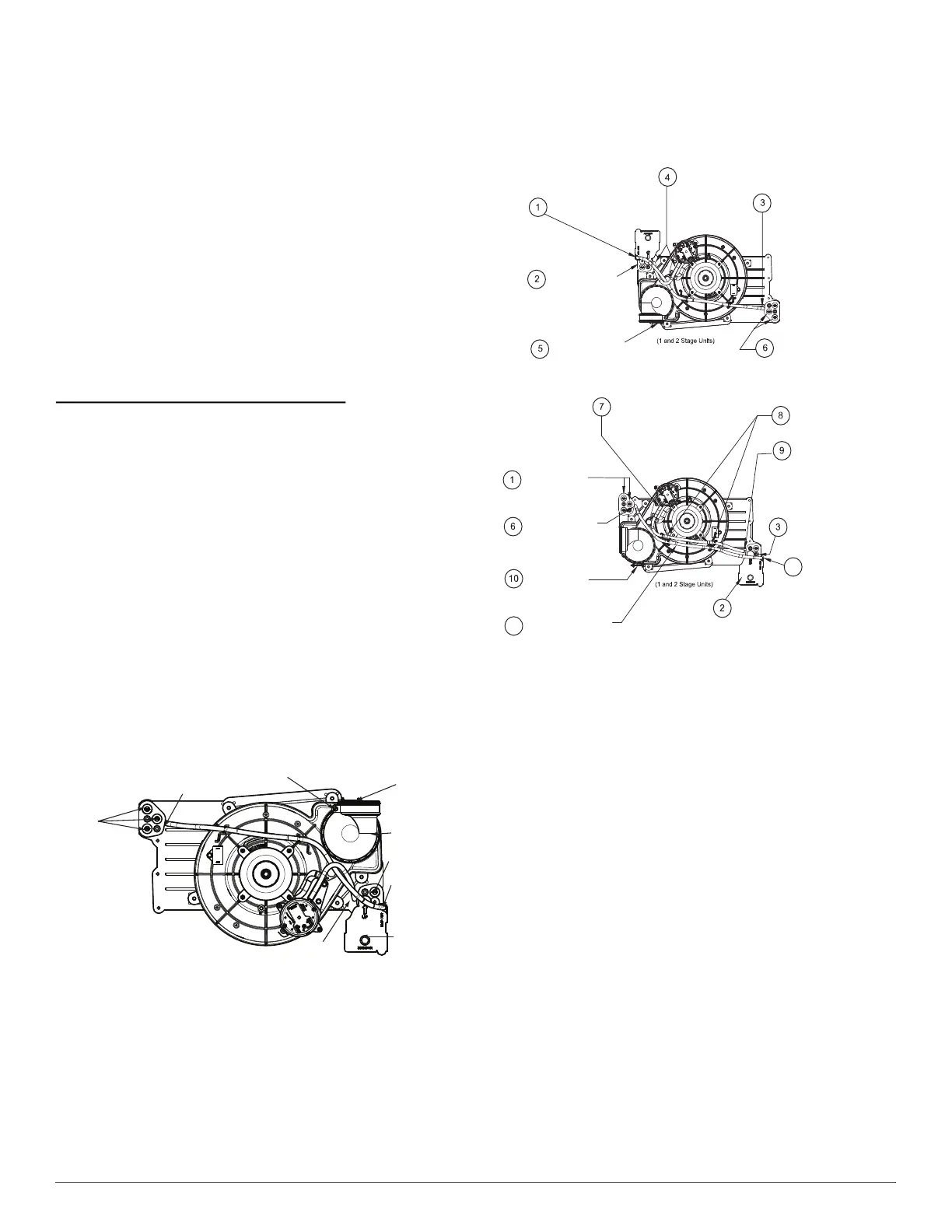

Condensate Trap - Upflow Orientation

When the furnace is installed in the upflow position, it is not necessary

to relocate the condensate trap or associated tubing. Refer to Fig. 8 for

upflow condensate trap information. Refer to Condensate Drain section

for information how to install the condensate drain.

A11307

Fig. 8 – Upflow Trap Configuration

(Appearance may vary)

Condensate Trap - Downflow Orientation.

When the furnace is installed in the downflow position, the condensate

trap will be initially located at the upper left corner of the collector box,

as received from the factory. See the top image in Fig. 9. When the

furnace is installed in the downflow orientation, the condensate trap

must be relocated for proper condensate drainage. See the bottom image

in Fig. 9.

To Relocate the Condensate Trap:

• Orient the furnace in the downflow position.

• Fig. 9 shows the condensate trap and tubing before and after

relocation. Refer to Fig. 9 to begin the trap conversion.

• Refer to Condensate Drain section for information how to install the

condensate drain.

A11587

Fig. 9 – Downflow Trap Configuration

(Appearance may vary)

Condensate Trap - Horizontal Orientation.

When the furnace is installed in the horizontal right position, the

condensate trap will be initially located at the bottom of the collector

box, as received from the factory. See the top image in Fig. 10. When the

furnace is installed in the horizontal left position, the condensate trap

will be initially located at the top of the collector box, as received from

the factory. See the top image in Fig. 11. In both cases the trap must be

repositioned on the collector box for proper condensate drainage. See the

bottom images in Fig. 10 and Fig. 11.

A field-supplied, accessory Horizontal Installation Kit (trap grommet) is

required for all direct-vent horizontal installations (only). The kit

contains a rubber casing grommet designed to seal between the furnace

casing and the condensate trap. See Fig. 18.

Condensate Trap

Relief Port

Collector Box

Plugs

Pressure Switch

Port

Condensate Trap

Outlet

Condensate Trap

Relief Port

Collector Box

Plug

Vent Elbow

Vent Elbow Clamp

Vent Pipe Clamp

UPFLOW TRAP CONFIGURATION

1 & 2 Stage Units

Remove relief tube from relief

port on condensate trap.

Remove the screw

that secures the trap

to the collector box and

remove trap.

Loosen clamp on inlet

to vent elbow.

Remove pressure switch tube from

front pressure switch and discard. A

new tube is shipped in the loose parts bag.

Remove tube from relief port.

Remove middle and bottom

plugs. DO NOT DISCARD.

Unconverted Factory Configuration as

Viewed in the Downflow Orientation

Install the two plugs

previously removed

on the open ports

of the collector box.

Connect relief tube

to port on collector

box.

Rotate elbow to

desired position and

tighten clamp to

15 lb.ïin.

Slide tube in standïoffs

to adjust length.

Connect the new pressure switch

tube from Loose Parts bag to

port on front pressure switch.

Route tube through inducer

standïoffs to adjust position

of the tube.

Trim excess tube.

Connect pressure switch

tube to port on collector

box.

Attach condensate trap

with screw to collector box.

Connect relief tube to

relief port on condensate

trap.

Align condensate trap

over middle and bottom

ports of collector box.

4

5

Downflow Trap Configuration

Loading...

Loading...