926SB: Installation, Start-up, Operating, Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

23

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90 degree elbow and 10

ft. (3 M) of main duct to the first branch take-off may require internal

acoustical lining. As an alternative, fibrous ductwork may be used if

constructed and installed in accordance with the latest edition of

SMACNA construction standard on fibrous glass ducts. Both acoustical

lining and fibrous ductwork shall comply with NFPA 90B as tested by

UL Standard 181 for Class 1 Rigid air ducts.

NOTE: For horizontal applications, the top most flange may be bent

past 90_ to allow the evaporator coil to hang on the flange temporarily

while the remaining attachment and sealing of the coil are performed.

GAS PIPING

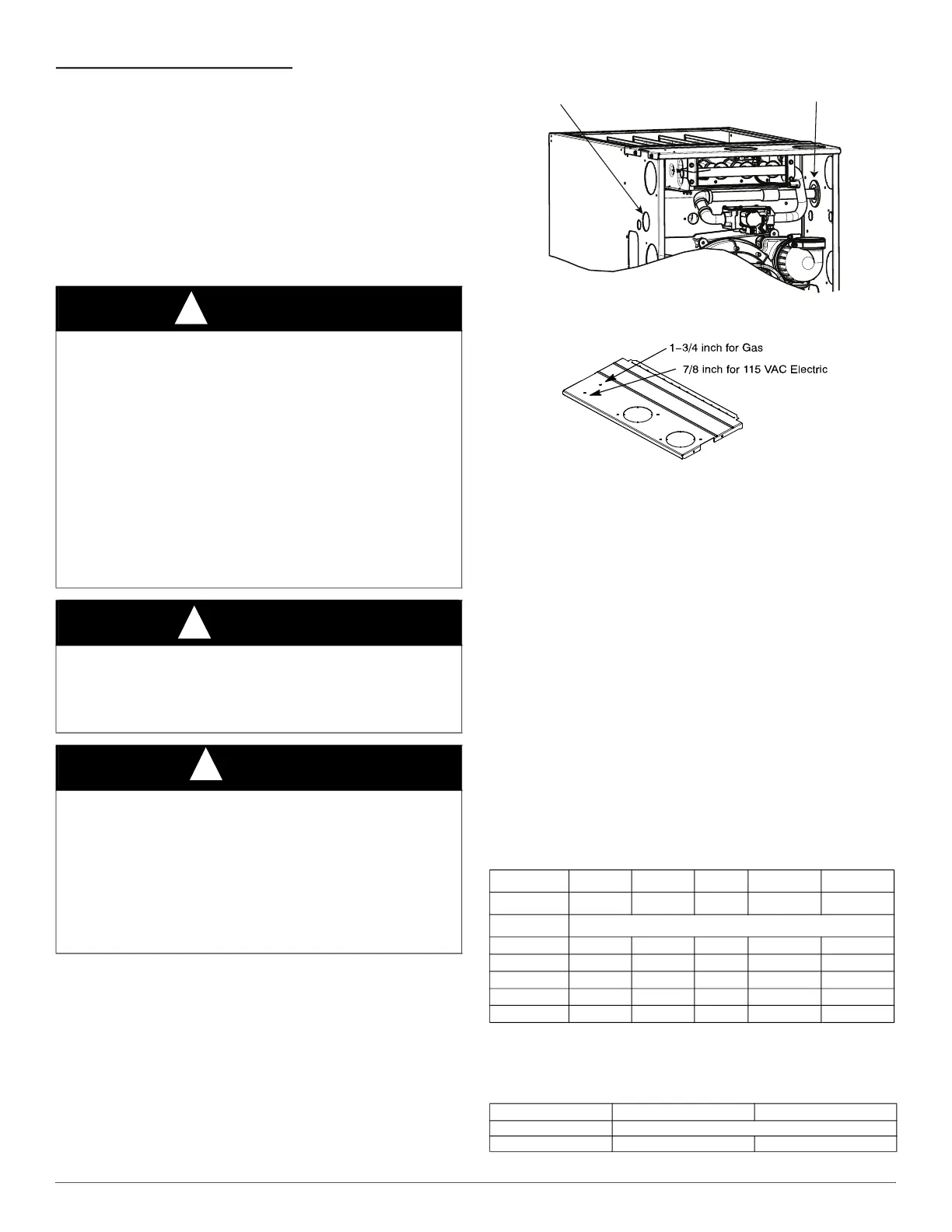

A11338

Fig. 30 – Gas Entry

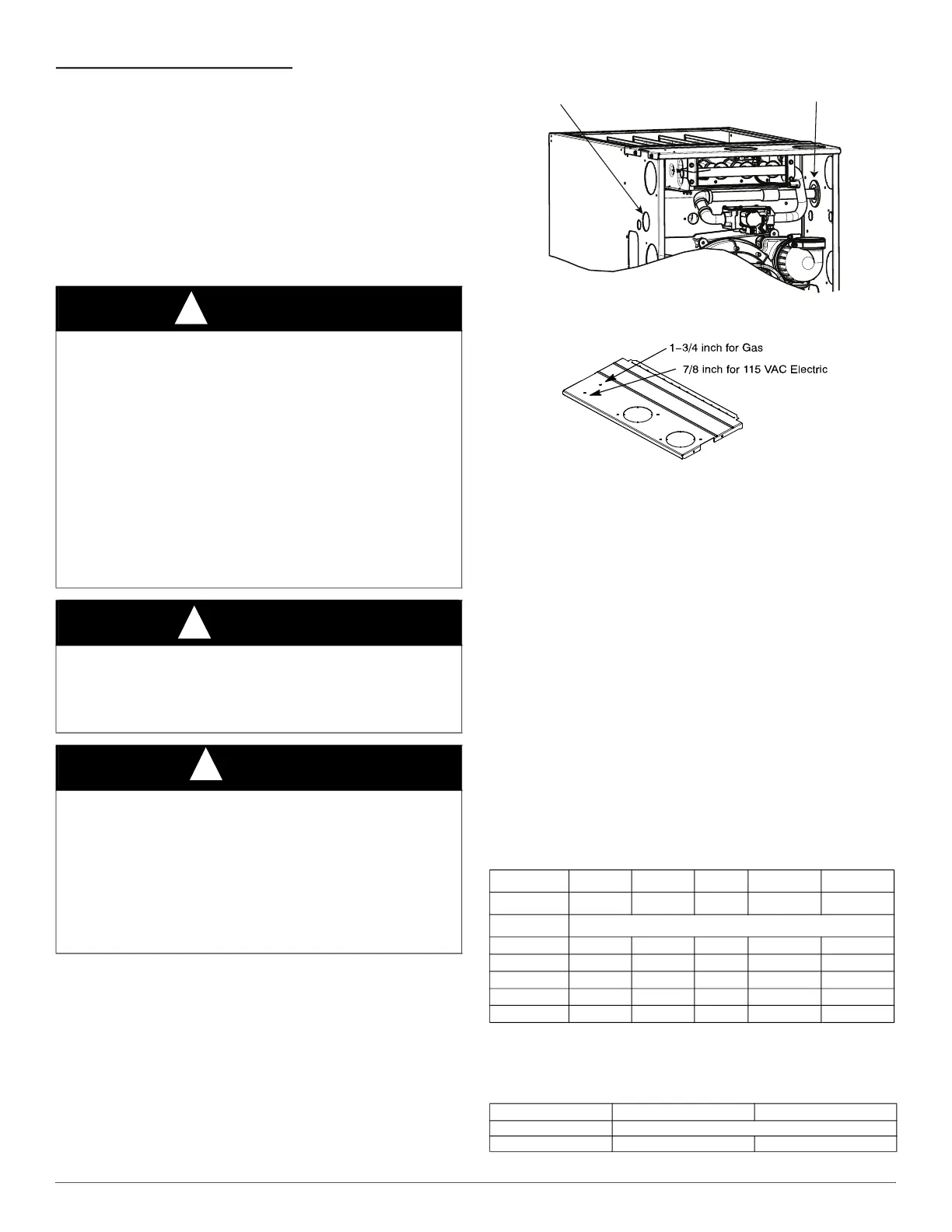

A230050

Fig. 31 – Alternate Gas and Electric Entry

NOTE: Top plate may be field drilled for alternate gas and 115 VAC

electric entry.

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFPA 54/ANSI Z223.1 in the USA.

Refer to current edition of NSCNGPIC in Canada.

Installations must be made in accordance with all authorities having

jurisdiction. If possible, the gas supply line should be a separate line

running directly from meter to furnace.

NOTE: Use a back-up wrench on the inlet of the gas valve when

connecting the gas line to the gas valve.

The gas supply pressure shall be within the maximum and minimum

inlet supply pressures marked on the rating plate with the furnace

burners ON and OFF.

Refer to Table 11 for recommended gas pipe sizing. Risers must be used

to connect to furnace and to meter. Support all gas piping with

appropriate straps, hangers, etc. Use a minimum of one hanger every 6

ft. (2 M). Joint compound (pipe dope) should be applied sparingly and

only to male threads of joints. Pipe dope must be resistant to the action

of propane gas.

Table 11 – Maximum Capacity of Pipe

NOTE: Cubic ft. of natural gas per hr for gas pressures of 0.5 psig

(14-in. w.c.) or less and a pressure drop of 0.5-in. w.c. (based on a 0.60

specific gravity gas). Ref: Chapter 6 current edition of NFPA 54/ANSI

Z223.1.

WARNING

!

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury, death,

and/or property damage.

Never purge a gas line into a combustion chamber. Never test for gas

leaks with an open flame. Use a commercially available soap solution

made specifically for the detection of leaks to check all connections. A

fire or explosion may result causing property damage, personal injury

or loss of life.

Use proper length of pipe to avoid stress on gas control manifold and

gas valve.

Gas valve inlet and/or inlet pipe must remain capped until gas supply

line is permanently installed to protect the valve from moisture and

debris. Also, install a sediment trap in the gas supply piping at the inlet

to the gas valve.

CAUTION

!

FURNACE DAMAGE HAZARD

Failure to follow this caution may result in furnace damage.

Connect gas pipe to furnace using a backup wrench to avoid damaging

gas controls and burner misalignment.

NOTICE

!

In the state of Massachusetts:

1. Gas supply connections MUST be performed by a licensed plumber

or gas fitter.

2. When flexible connectors are used, the maximum length shall not

exceed 36 in. (915 mm).

3. When lever handle type manual equipment shutoff valves are used,

they shall be T-handle valves.

4. The use of copper tubing for gas piping is NOT approved by the state

of Massachusetts.

Nominal: 1/2 (12.7) 3/4 (19.0) 1 (25.4) 1-1/4 (31.8) 1-1/2 (38.1)

Actual ID: 0.622 0.824 1.049 1.380 1.610

Length (ft) Capacity in Cubic Feet of Gravity

10 (3.0)

172 360 678 1390 2090

20 (6.0)

118 247 466 957 1430

30 (9.1)

95 199 374 768 1150

40 (12.1)

81 170 320 657 985

50 (15.2)

72 151 284 583 873

Gas Pressure Natural (in. w.c.) Propane (in. w.c.)

Maximum 13.8

Minimum 4.5” 12”

Gas Pipe Grommet Required

For Direct Vent Applications

Left Side Gas Entry. Gas Pipe

Grommet Required For Direct

Vent Applications.

Loading...

Loading...