06/23

9

Therefore, as the thickness of the test material is increased, the required voltage also increases, and this

in turn leads to an increase in the Corona Discharge current. As the width of the material is increased,

or the speed of the material is increased, the Material Draw current is also increased. These physical

factors must be considered when specifying an HV system. The sum of the Corona Current and

Material Draw Current is the Total Quiescent Demand Current, Iq for convenience.

Buckleys have material testing capability and are pleased to offer advice on the expected Corona

and Material Draw currents for planned installations, however, due to the nature of discharges and their

very specific dependence on the surroundings and environment, this advice can only ever be general

in nature.

Instrument Output Limits

Buckleys DCCT instruments are designed to provide a limited output current, primarily to ensure that the

output remains within the limits specified by the IEEE to prevent a lethal shock to anyone accidentally

touching the HV electrodes or wiring. This has the effect of limiting the output power at any given

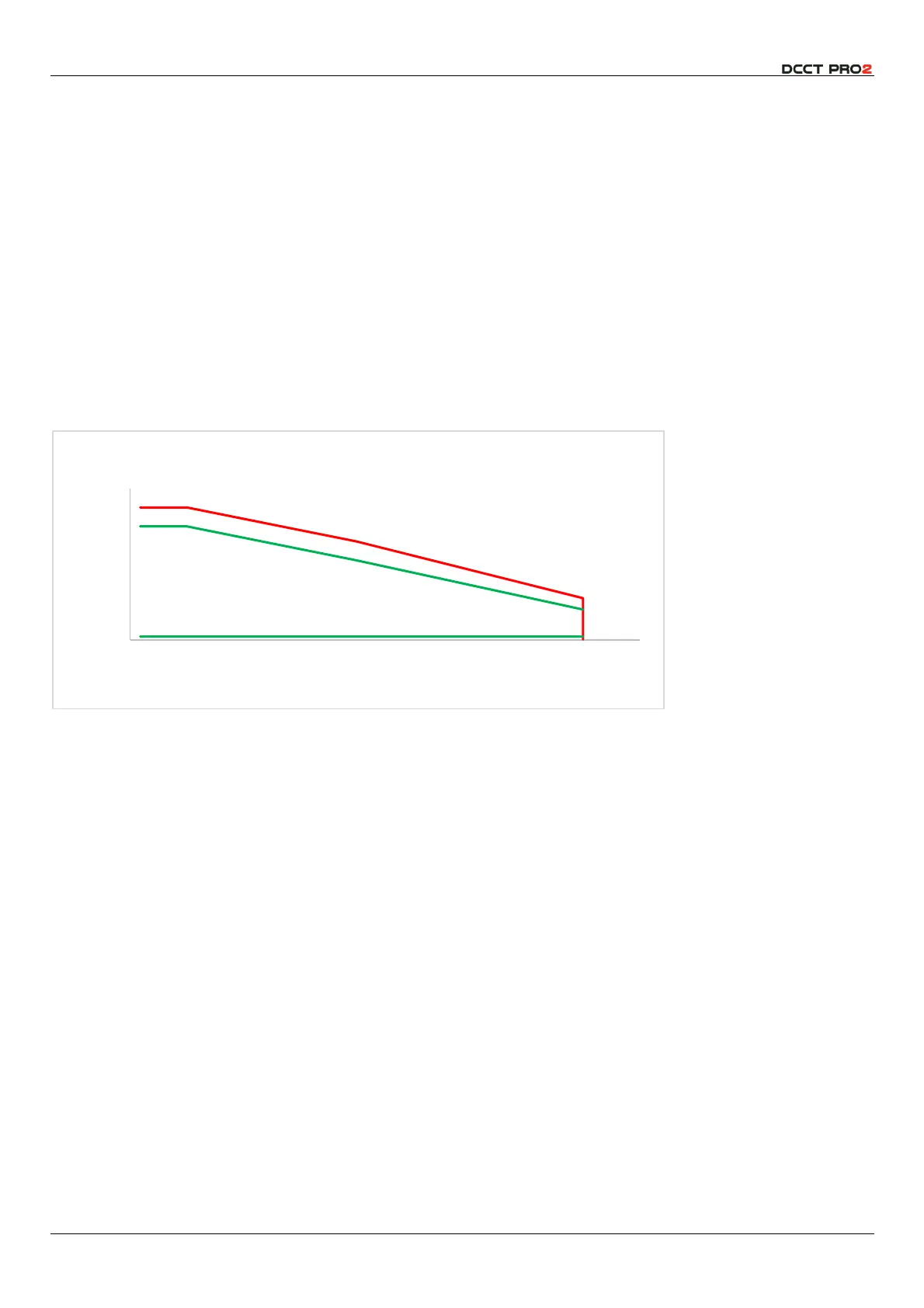

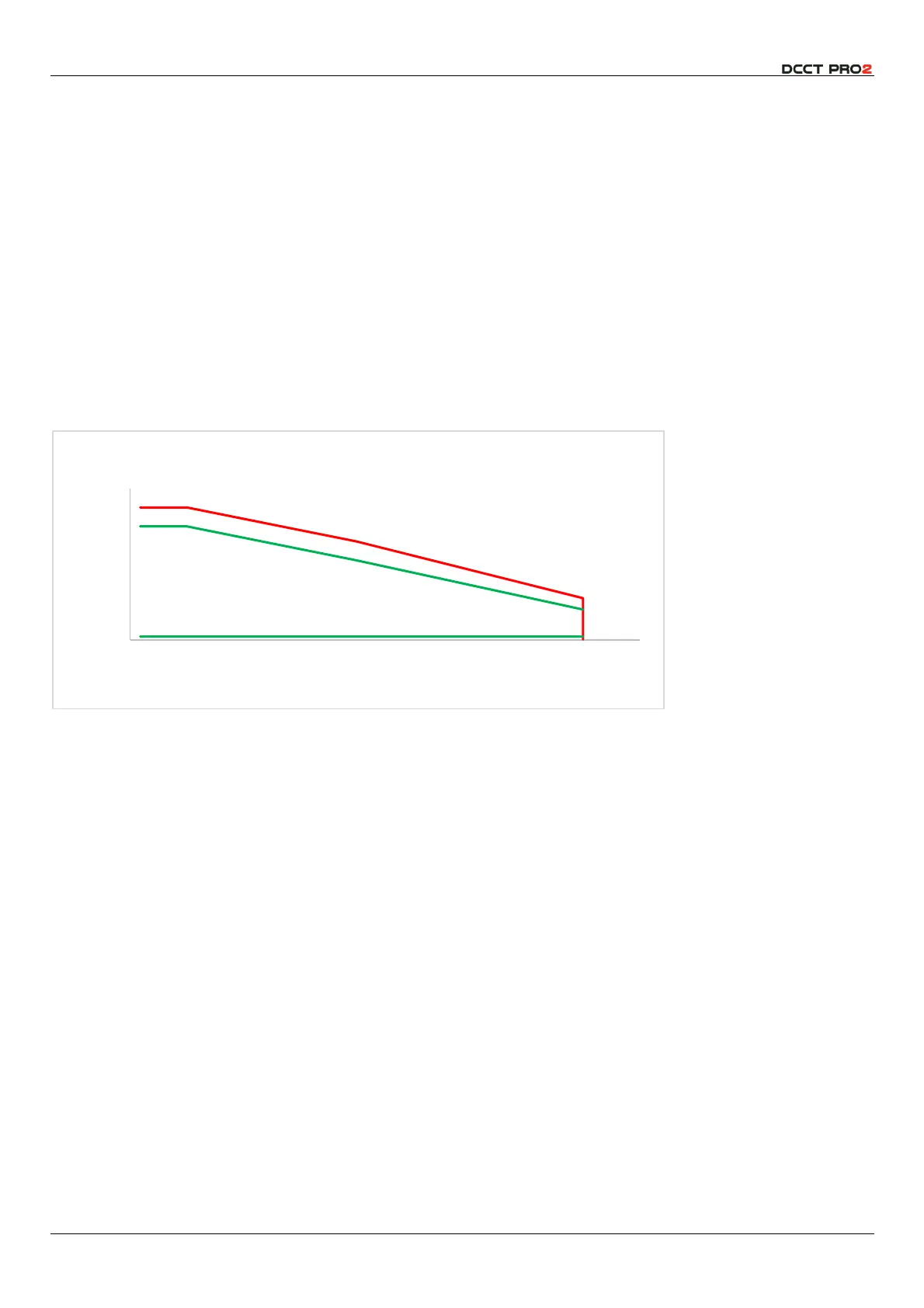

voltage, as can be seen in the graph in Fig 2.

Fig 2 - Typical Output Performance at 40kV

The red line on the graph in Fig 2 shows the performance limit as a limit for continuous current across the

range of output voltage of the DCCT instrument. Ideally, the current demand Iq at the required

voltage will fall in the zone outlined in green. However, if the demand current Iq is sufficiently high, it will

cause the output voltage to drop. Provided that the resultant voltage remains sufficiently high to carry

out the test reliably, this is acceptable. However, if it leads to a voltage below the necessary minimum,

the test may not detect flaws. This inevitably leads to a situation where some combinations of material

thickness, extrusion width, and extrusion speed, will exceed the output of a single instrument.

In order to counteract this constraint, Buckleys have introduced a range of multi-channel instruments in

which a user interface is able to control more than one generator. Each generator can supply sufficient

current to energise an electrode of a given size, and multiple generators can then be used to ensure

the total electrode width is sufficient to carry out the test on the full width of material, at the desired

extrusion speed.

This approach provides economic and ergonomic advantages:

•

It is cheaper than providing several complete instruments.

•

It is considerably simpler to install, particularly if interlocking and remote control are require.

•

It is easier to control, with a single setting process controlling all outputs simultaneously.

•

The instruments each provide individual alarm counters and outputs, and these can be grouped

into a single overall alarm if required.

0

50

100

150

200

250

300

350

400

0 5 10 15 20 25 30 35 40 45

Maximum Output Current

Output Voltage

Continuous Output Current Capability

Loading...

Loading...