5

Boiler installation

Logano G234X – 6 720 804 886 (2012/08)16

In Canada the regulations in accordance with CAN/CSA B 149.1 and 2

Installation Codes apply.

5.7.3 Installing the flue pipe

▶ Mount the flue pipe on the flue outlet of the draft hood.

▶ Mount the flue pipe (4) with corrosion-resistant sheet metal screws.

5.7.4 Connecting flue pipe

Use only flue pipes with a suitable diameter for the boiler.

Every horizontal section of the flue pipe must have a minimum rise of

¼ inches per foot (21 mm per m) towards the chimney. The flue pipe

must be securely fastened to prevent it from hanging. A suspension must

be installed at least every 5 feet (1.5 m). Fasten every connection with

at least three (3) corrosion-resistance sheet metal screws. The end

section of the flue pipe must connect to the inside of the chimney smoke

duct.

A minimum clearance of 6 inches (155 mm) is required between the flue

pipes and all flammable materials.

The flue pipe must not be reduced in size and venting must not be

prevented by the installation of additional components.

▶ Connect flue pipe to the chimney with the shortest possible length of

flue pipe.

5.7.5 Installation of vent damper

Only the vent damper supplied with the boiler must be used for venting

the boiler.

The position of the vent damper must be visible.

The back flow check must be at least 6 inches (155 mm) from all

flammable components.

The vent damper must be freely accessible for maintenance.

The vent damper must be open when the main burner of the boiler is

operating.

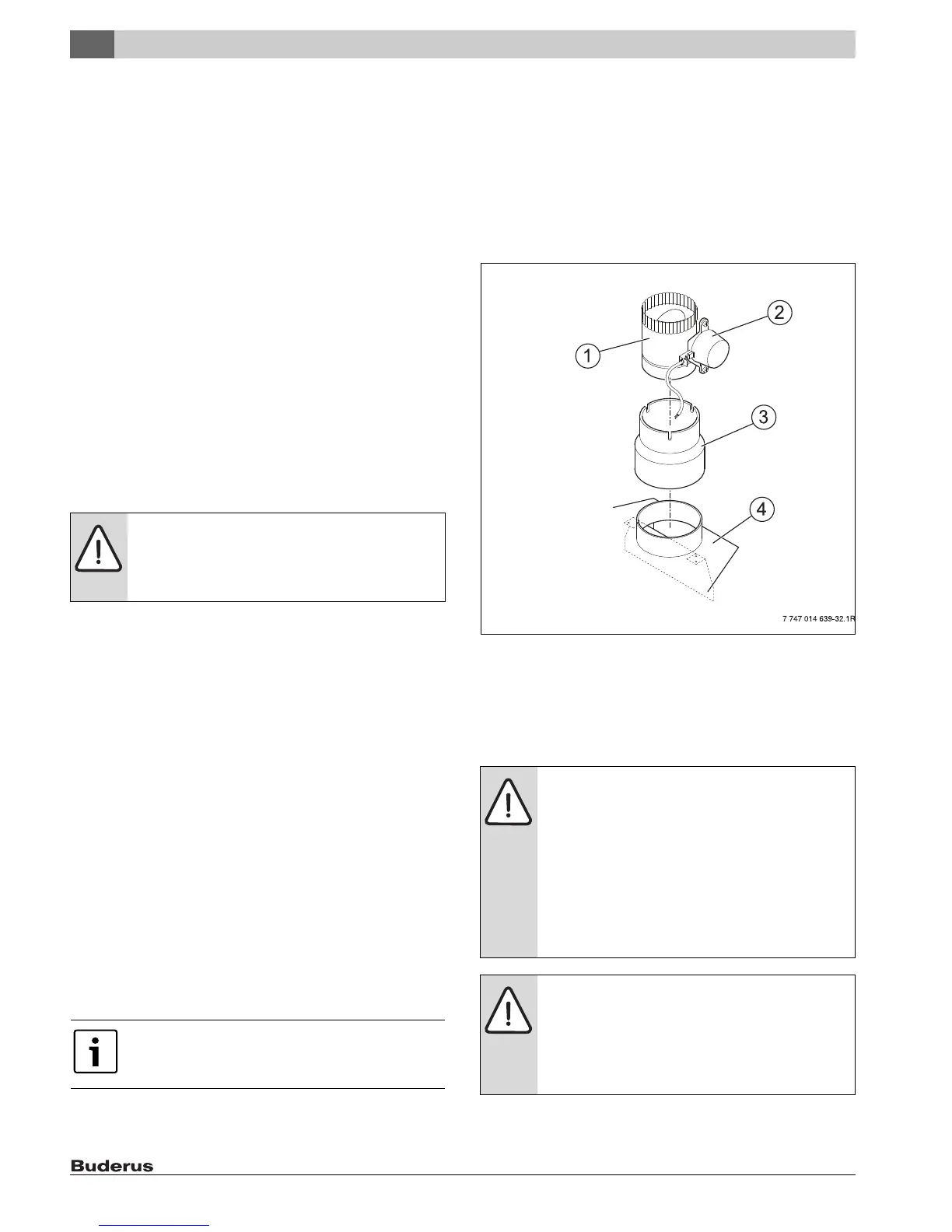

▶ Place flue gas adapter [3] on the pipe nipples of the draft diverter.

▶ Install pins in the hole of the vent baffle [1].

▶ Fasten flue baffle to the flue connector adapter with three (3)

corrosion-resistant self-tapping screws.

Fig. 15 Installation of vent damper

[1] Vent Damper

[2] Motor

[3] Adapter for the flue outlet

[4] Draft hood

5.7.6 Installing electrical connection of vent damper

▶ Disconnect all electrical power to your heating system.

D Start up the heating system to be tested. Follow the instructions

for commissioning. Set the thermostat for continuous

operation.

E After the main gas burner has been operating for five minutes,

check the opening at the back flow check for drafts with a match

flame or a candle, or with the smoke of a cigarette, cigar or pipe.

F Check this way that all heating systems that remain connected

to the venting system have been checked as above to ensure

that the venting operates properly. Then place all doors,

windows, venting fans, exhaust system flaps, and all other gas

fired appliances back into their original state.

G Any incorrect status of the common venting system must be

corrected to ensure that the heating system complies with the

regulations of the National Fuel Gas Code, ANSI Z 223.1. If the

size of any component of the common venting system is

changed, the complete venting system must be resized to

comply with the relevant tables in Part 11 of the National Fuel

Gas Code, ANSI Z 223.1.

DANGER: Risk of fatal injury from escaping flue gases!

A draft hood that does not work properly can cause

dangerous flue gases to escape.

▶ Note that the draft hood check cannot be modified.

In Canada the vent damper must not be installed on a

propane-fired heating system with a electronic ignition

system.

DANGER: Risk of fatal injury from electric shock!

▶ Only qualified electricians are permitted to carry out

electrical work.

▶ Before opening the appliance, disconnect it from the

power supply by means of the emergency shutoff

switch or the relevant circuit breaker in the main fuse

board.

▶ Take measures to ensure that the heating system

cannot be switched on again unintentionally.

▶ Please observe all installation instructions.

DANGER: Fire hazard from hot boiler components!

Hot boiler components may damage electrical cables.

▶ Ensure that the electrical cables are not touching any

hot parts.

▶ Make sure that all cables are routed through the

conduits provided.

Loading...

Loading...