7

Taking the heating system out of operation

Logano G234X – 6 720 804 886 (2012/08) 23

7 Taking the heating system out of operation

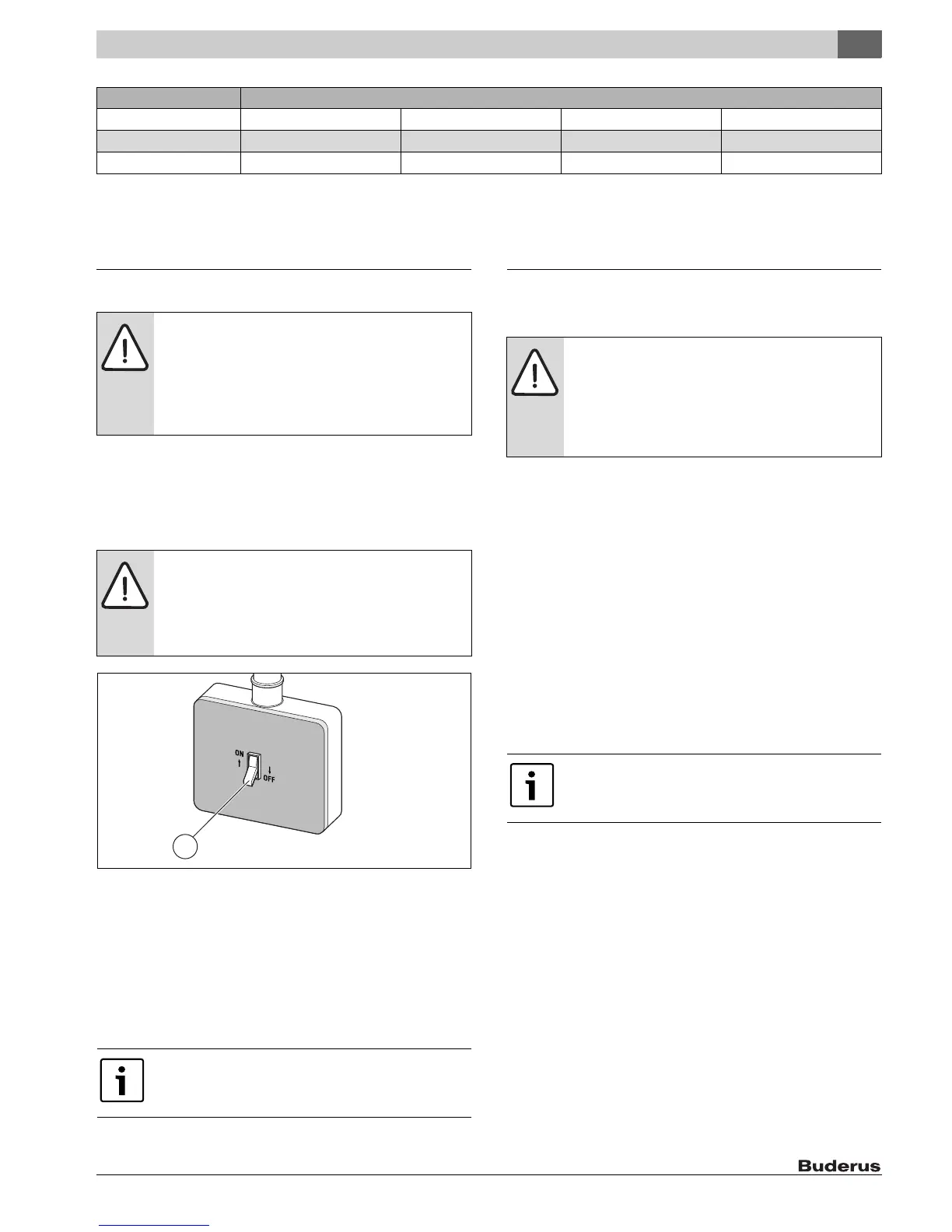

7.1 Normal system shut-down

▶ Turn ON/OFF switch (emergency shutoff switch) to OFF position. This

shuts off power to the boiler and all of its components (e.g. burner,

temperature controller).

▶ Turn ON/OFF knob on gas valve clockwise to OFF position.

Fig. 30 Emergency shut-down

[1] ON/OFF switch (Emergency shutoff switch)

7.2 Emergency shut-down procedures

Inform the owner and operator of the procedure in case of emergency:

▶ Never put yourself at risk. Your own safety must always take priority.

▶ Shut off main gas supply.

▶ Shut down the heating system using the boiler emergency shutoff

switch or the corresponding circuit-breaker.

8 Boiler inspection and maintenance

When carrying out maintenance work, observe:

▶ Always check that the heating system is working properly after

carrying out any maintenance work.

8.1 Why is regular maintenance important?

Heating systems must be serviced annually for the following

reasons:

• to maintain a high level of efficiency and to operate the system

economically (low fuel consumption)

• to achieve a high level of operational safety

• to maintain the cleanest possible combustion

• to ensure reliable operation and a long service life.

Maintenance work may only be carried out by a trained and certified

installer. If parts are replaced, only Buderus approved components may

be used. Maintenance must be carried out once a year. The results of the

inspection must be recorded in the maintenance log ( page 29).

8.2 Testing the flue system, including combustion air

supply, air inlet and Ventilation openings

Check the venting system, including the combustion air, inlet and outlet

openings. All faults must be repaired immediately. Make sure that the

combustion air supply and the inlets and outlets are not blocked at any

point.

8.3 Inspection of the boiler and burner

▶ Perform a visual inspection of the boiler and burner for external

contamination.

▶ If contamination is found, clean the boiler and burner.

Main gas orifice identification of the main gas nozzles (0 - 8500 ft / 0 - 2591 m)

Boiler capacity 38 45 55 64

Natural gas

1)

1) factory setting

3.70 3.70 3.50 3.80

LP (=Liquid Propane)

2)

2) Only convert natural gas to propane gas according to chapter 5.4.2, page 13.

2.20 2.40 2.30 2.45

Table 12 Main gas orifice identification

NOTICE: Risk of system damage due to freezing!

The heating system can freeze up in cold weather if it is

switched off.

▶ Protect your system from freezing by draining the

boiler, the heating system and hot water pipes at the

lowest point.

NOTICE: System damage due to freezing.

The heating system can freeze up in cold weather if it is

shut down.

▶ Protect the heating system from freezing by draining

the boiler and water pipes at the lowest point.

Use the heating system emergency shut-off switch

located outside the boiler room or the heating system

circuit breaker for emergency shutdown.

Loading...

Loading...