20

Replacing the valve seat

Type 2000, 2002, 2012

8 REPLACING THE VALVE SEAT

Remove the actuator from the valve body

→ Clampthevalvebodyinaholdingdevice.

NOTE!

Damage to the seat seal or the seat contour!

▶ Whenremovingtheactuator,ensurethatthevalveisinopenposition.

→ ControlfunctionAandI:pressurizethelowercontrolairconnectionwithcompressedair(5bar):valve

opens.

→ Usingasuitableopen-endwrench,placethewrenchatonthetube.

→ Unscrew the actuator from the valve body.

→ Carefullyremoveoldgraphitesealfromthevalvebody.

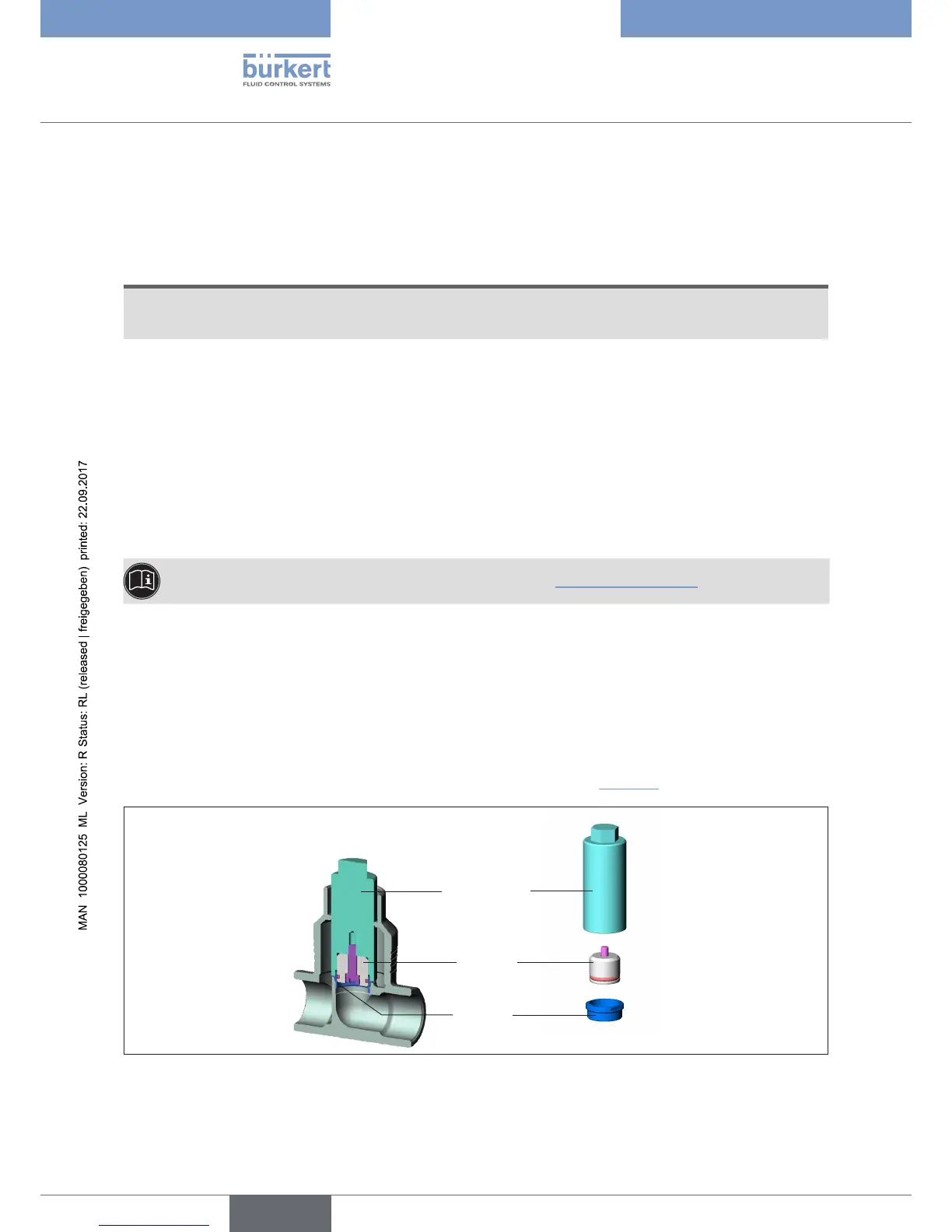

Replacing valve seat

→ Unscrewoldvalveseatusingtheinstallationtoolandopen-endwrench.

Information on the assembly tool can be found in chapter “10Installationtools”.

→ Cleanthreadandsealingsurfaceinthebodyusingcompressedair.

→ Select tool insert and screw into the installation tool.

→ Attach new valve seat to the installation tool.

→ Greasethreadwithalubricant(e.g.KlüberpasteUH196-402).

→ Place attached valve seat on the body thread and screw on by hand.

→ Usingatorquewrench,tightentothespeciedtighteningtorque(see“Table5”).

Installation tool

Toolinsert

(accordingtonominal

width of seat)

Valve seat

Figure 6: Replacing the valve seat

Loading...

Loading...