INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 39 of 67

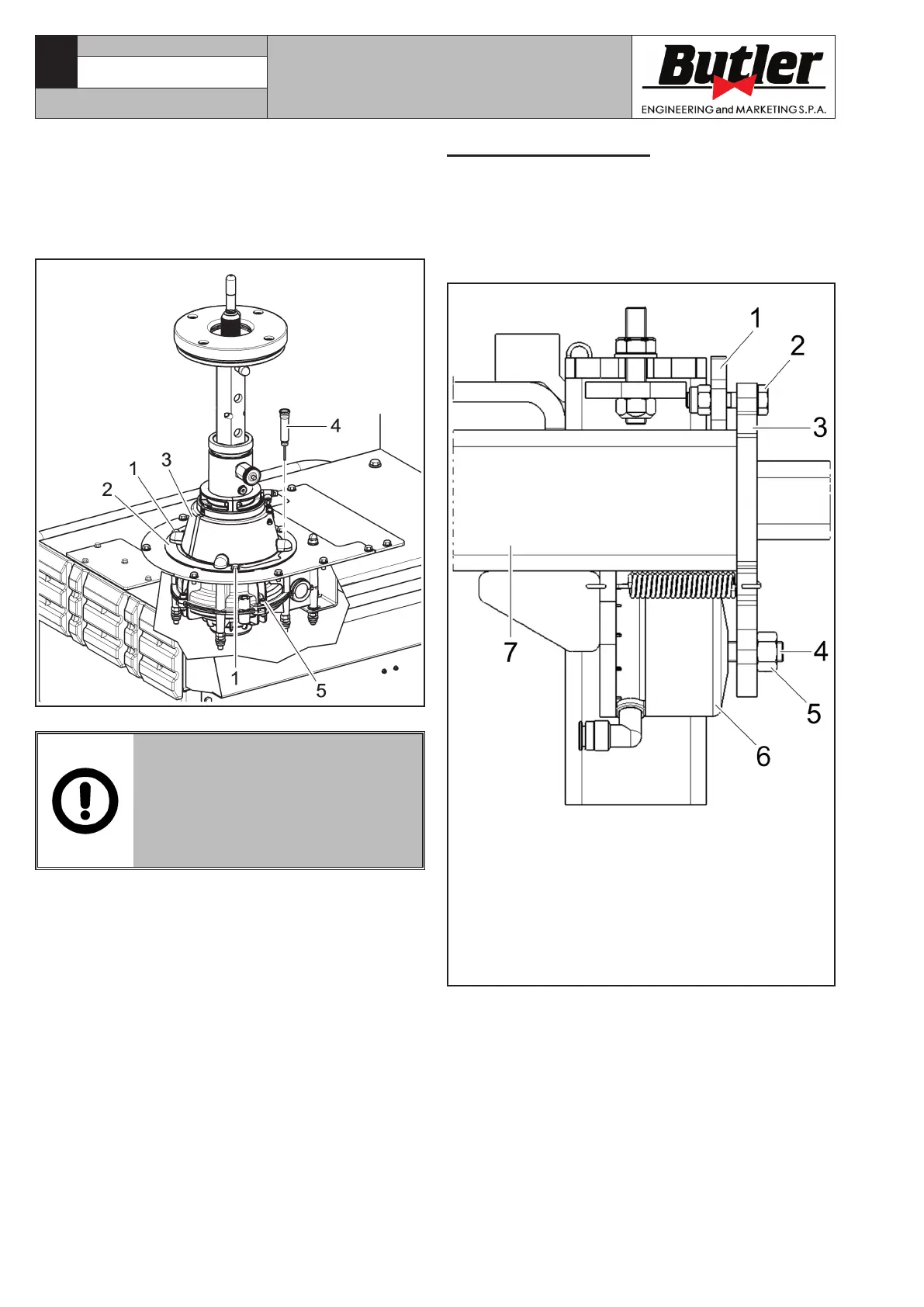

• Periodically (at least every 100 working hours) check

reduction gear lubricating oil level (Fig. 53 ref. 5).

Such operation must be effectuated unscrewing the

screws (Fig. 53 ref. 1), removing the flange (Fig. 53

ref. 2), the guard (Fig. 53 ref. 3) and the plug

(Fig. 53 ref. 4) on the reduction gear.

Fig. 53

ANY DAMAGE TO THE MACHINE

DEVICES RESULTING FROM THE

USE OF LUBRICANTS OTHER

THAN THOSE RECOMMENDED

IN THIS MANUAL WILL RELEASE

THE MANUFACTURER FROM ANY

LIABILITY!!

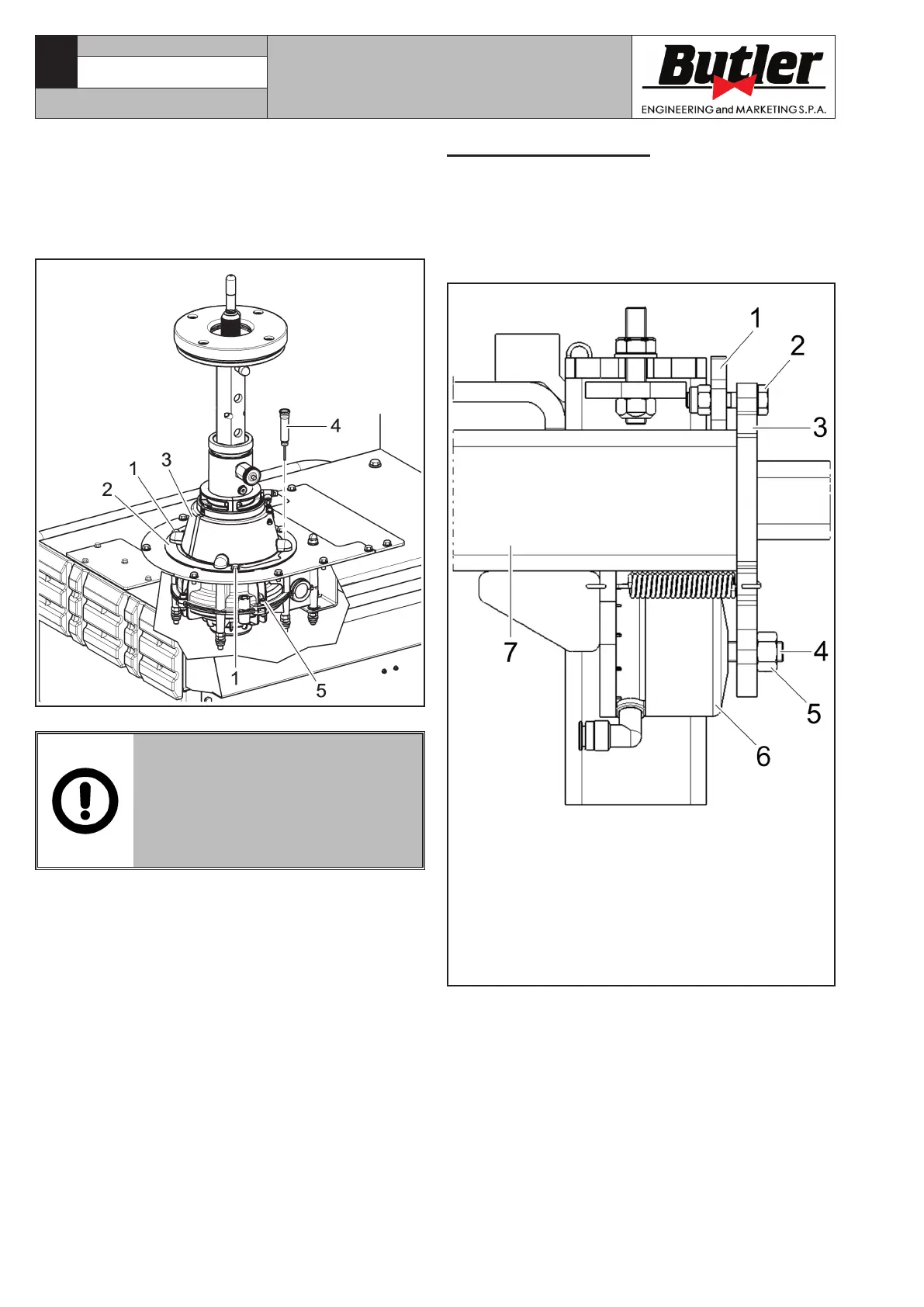

14.1 Neck adjustment

In case of fulcrum-type screws (Fig. 54 ref. 2) with

neck (Fig.

54 ref. 3) fully beating onto bead breaking

arm’s guide (Fig.

54 ref. 7) (not on the adjusting plate

(Fig. 54 ref. 1)), carry out neck adjustment procedure

as described below.

Fig. 54

KEY

1 – Adjusting plate

2 – Fulcrum screws

3 – Neck

4 – Adjusting dowel

5 – Locking nut

6 – Neck operating cylinder

7 – Bead breaking arm guide

CAPTURE 4 - CAPTURE 4 FI

7104-M007-4_B

Loading...

Loading...