Installation

Embedded in the instrument enclosure is a built-in air

compressor. A unique electronic control system automatically

regulates the air pressure/flow to the optimum levels. No user

adjustments are necessary to achieve maximum performance.

Adjustments, if required, can be carried out in Service mode.

If an exterior alternate air source is desired, there is a hose

barb on the rear panel. The air source must be regulated to 10

PSI, offering 4L/min (measured in operational series) and be

free of oil, dust and airborne contaminates.

The air supply must not be oxygen enriched.

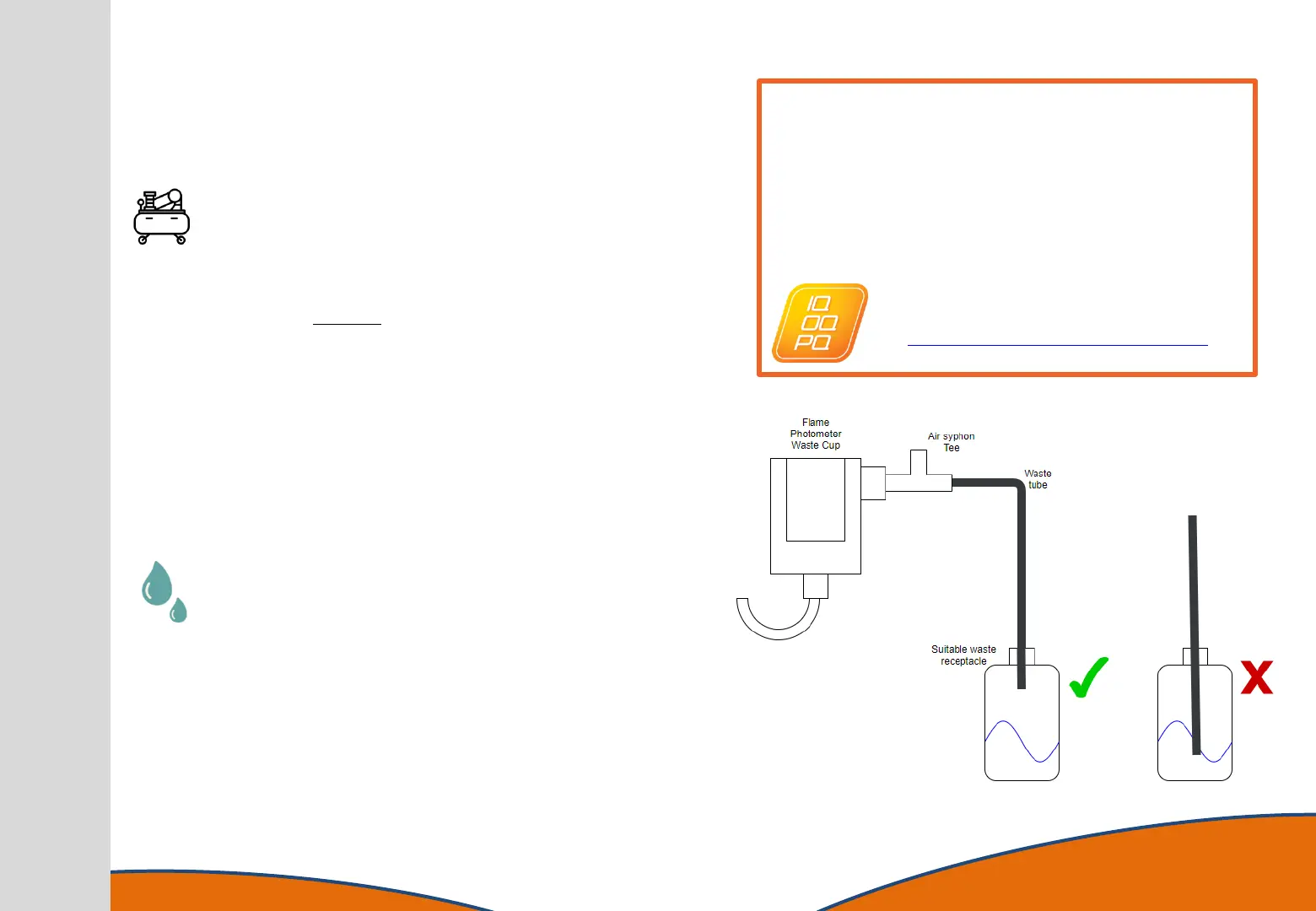

A sink or suitable container should be sited near the instrument

to dispose of the waste overflow from the Drain Cup. If a waste

container is used it should be situated so that the sides are

below the bottom of the Drain Cup. Attach the supplied silicone

tubing to the side port of the Drain Cup and route the other end

to the sink or waste container.

There should be a clear drain to waste without kinks or U-

sections and the end of the waste tube should be kept above

the water level in the waste bucket. The use of a T-piece just

after the drain cup is recommended to avoid the possibility of

forming a partial siphon.

NOTE: The end of the waste tube must never be submerged

below the waste liquid level as this may prevent the natural

draining of the beaker. This can cause erratic readings and

potentially flood the bench.

14

IQ OQ PQ

Our novel IQ OQ PQ programme enables a user to

successfully validate the installation of the new flame

photometer and operator functionality. Submission of the

report document to BWB results in certification for

performance and operation validation.

Find out more:

https://www.bwbtech.com/iq-oq-pq

Loading...

Loading...