MAINTENANCE

OPERATOR MANUAL

64

EPS14P

65

OM-EPS14P2019001-EN

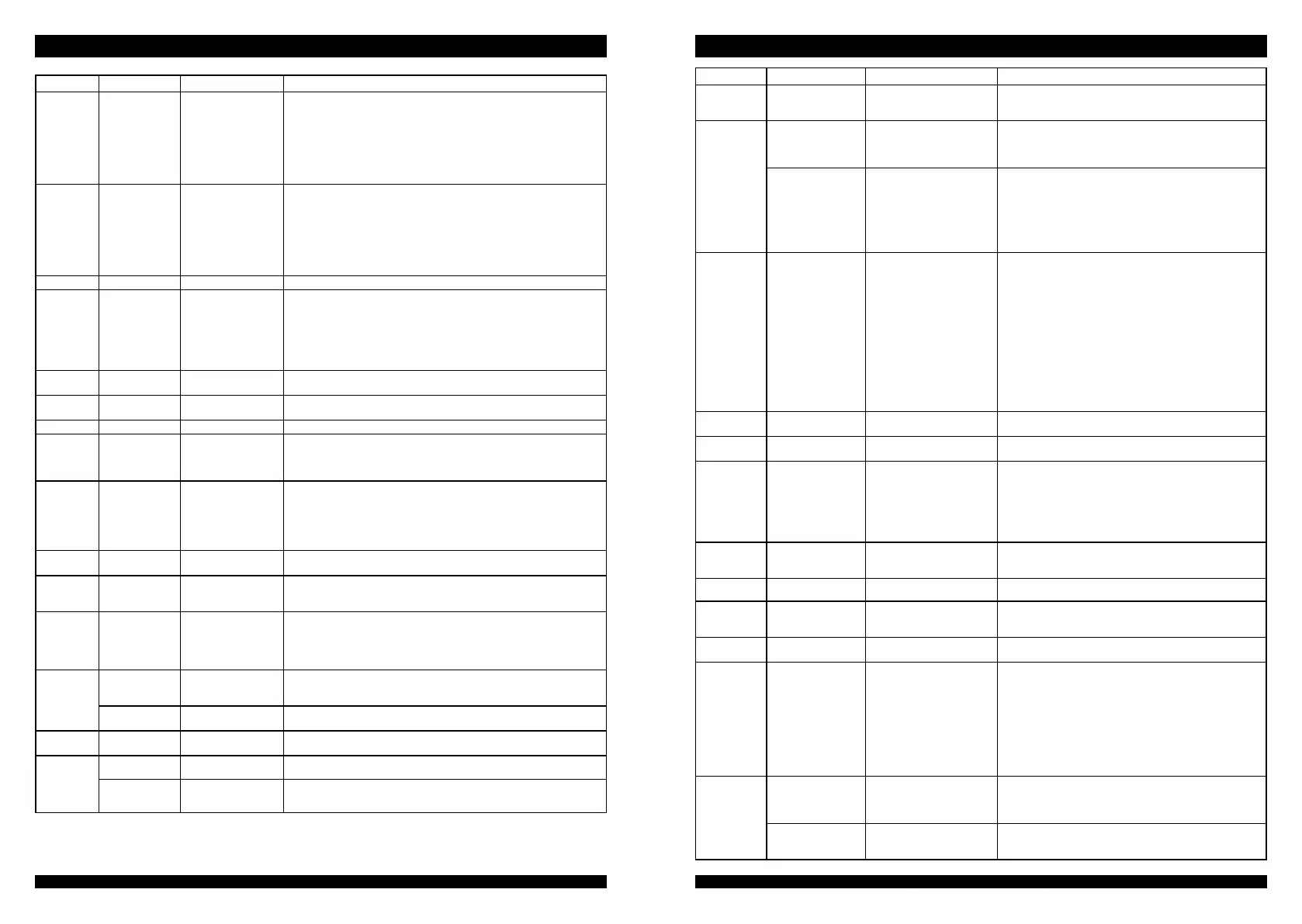

Display ALARM Fault name Recommended inspection

02A28 PUMP VMN LOW Oil pump VMN low

Possible cause: When the motor is turned on, the low-end voltage of

MOS tube is higher than 10% the normal battery voltage, or the phase

voltage is higher than 50% the battery voltage.

Possible causes:

1.Incorrect phase connection or faulty circuit of the motor. Check the

motor for incorrect phase connection. Check the motor for current

leakage to the ground. Check the motor for broken coil.

2.Replace the controller.

02A29 PUMP VMN

HIGH

Oil pump VMN high

Possible cause: When the motor is turned on, the low-end voltage of

MOS tube is higher than 10% the normal battery voltage, or the phase

voltage is higher than 50% the battery voltage.

Possible causes:

1.Incorrect phase connection or faulty circuit of the motor. Check the

motor for incorrect phase connection. Check the motor for current

leakage to the ground. Check the motor for broken coil.

2.Replace the controller

02A30 vmn low 3 phase wire fault Check the 3 phase wire of motor

02A31 vmn high VMN high

Possible cause: When the motor is turned on, the low-end voltage

of MOS tube is higher than 10% the normal battery voltage, or the

phase voltage is higher than 50% the battery voltage. Possible causes:

1. Incorrect phase connection or faulty circuit of the motor. Check the

motor for incorrect phase connection. Check the motor for current

leakage to the ground. Check the motor for broken coil. 2. Replace the

controller.

02A32 PUMP VMN NOT

OK

02A37 contactor closed Main contactor get

stuck

Check whether the main contactor get stuck

02A38 contactor open Main contactor open 1. Broken circuit of main contactor coil. 2. Main contactor damaged

02A40 AUX DRIV.SHRT. Short circuit of

auxiliary drive

Short circuit of drive circuit of electromagnetic brake or auxiliary

electric brake.Check for short circuit or low-impedance push-pull

output between A16 and –BATT. Fault with drive circuit of logic card.

Replace the controller.

02A41 WRONG

BATTERY

Fault with battery

setting

While the forklift is being started, the controller checks whether battery

voltage is within the nominal voltage range.

1. Check whether the “BATTERY VOLTAGE” setting in the “TESTER”

agrees with the indication of the voltmeter. In the case of disagreement,

change battery voltage setting to be the same as the measured value,

by using the “ADJUST BATTERY) function. 2. Replace the battery.

02A42 AUX DRIV.OPEN NFault with drive of

auxiliary output)

Drive circuit of auxiliary coil is unable to drive the load. Device itself or

drive coil is damaged. Replace the controller.

02A47 EVP2 NOT OK NAUX2 input voltage

is outside the range

Check whether NAUX2 input voltage is within the range. If not, re-

calibrate the maximum and minimum of NAUX2, and turn the key

switch to “ON” again. This fault will disappear.;

02A48 EVP1 NOT OK NAUX1 input voltage

is outside the range/

(CAD fault table: Open

circuit of proportional

valve drive circuit)

Check whether NAUX1 input voltage is within the range. If not, re-

calibrate the maximum and minimum of NAUX1, and turn the key

switch to “ON” again. This fault will disappear.

02A49 LIFT + LOWER Faults with lifting and

lowering exist at the

same time

1. Improper operation; 2. Self fault of lift and lowering switch; 3.

Replace the controller;

i=0 ever Drive current cannot

be stopped

If the connection of motor 3 phase wire has no problem, please replace

the controller

02A50 EVP1 COIL OPEN Open circuit of

NAUX1 coil

Check NAUX1 coil for open circuit, and whether EVP1 type setting is

correct.

02A51 EVP2 COIL OPEN

Open circuit of NAUX2

coil

Check NAUX2 coil for open circuit, and whether EVP2 type setting is correct.

TILLER OPEN

Tiller input switch is

disconnected

With the triller input switch disconnected, after a period approximately 30s

has elapsed, the main contactor will disengage and the warning will occur.

The warning will not occur next time the forklift is operated.

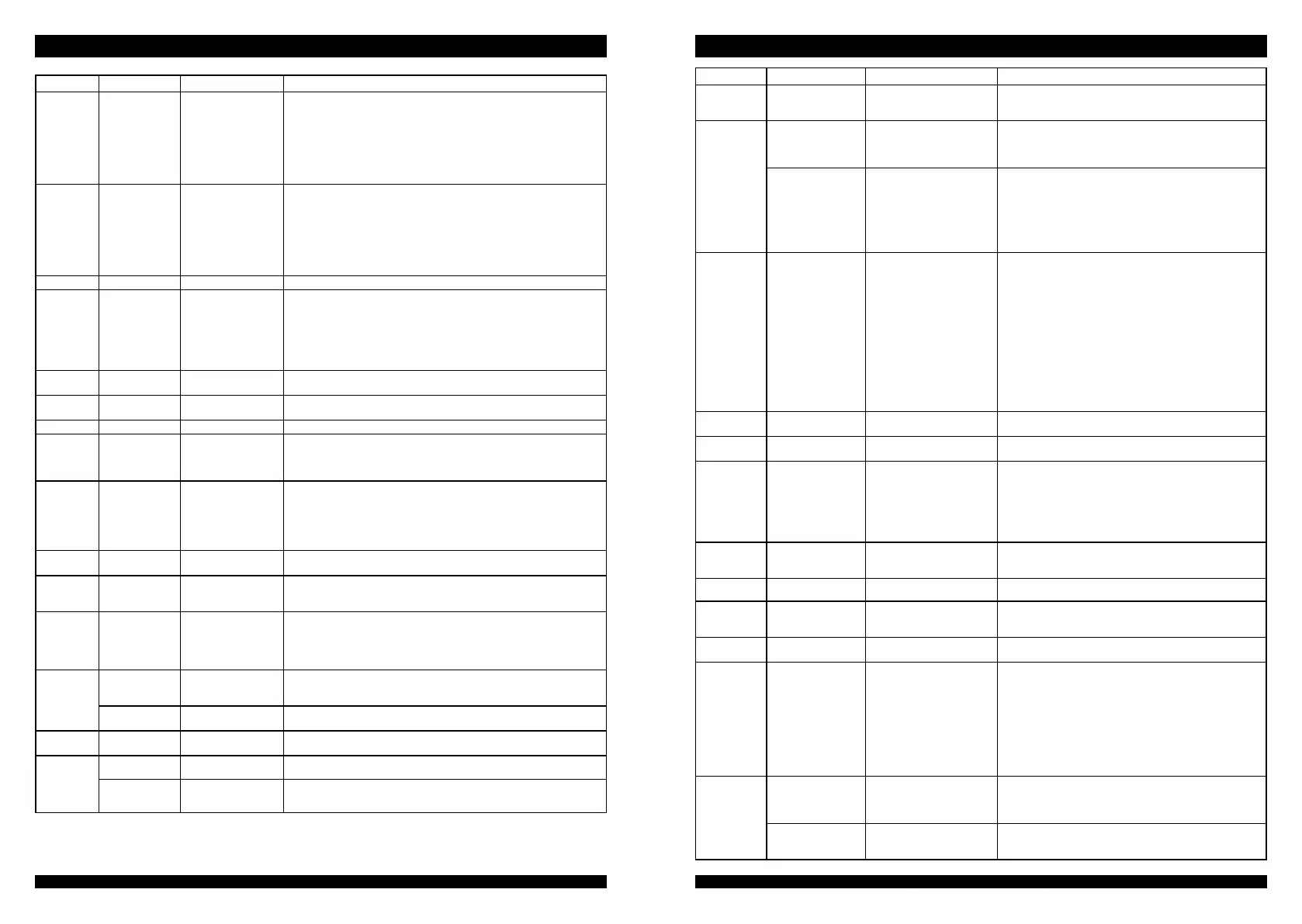

Display ALARM Fault name Recommended inspection

02A52 PUMP I=0 EVER Oil pump I=0 fault

Check whether the power supply line of the oil pump

motor is in good condition. If the line is in good condition,

replace the controller;

02A53

STBY I HIGH Standby current is high

The micro controller system has detected that the signal

of the current sensor is outside the permissible range of

current with the forklift in the idling state. This fault is

irrelevant to external components. Replace the controller.

WRONG ZERO Error of zero voltage

While the forklift is being started, feedback value of high

end voltage of VMN is not in the order of 2.5V. Circuit of the

controller is damagedFault analysis: The following checks are

recommended.Check internal connection of the motorCheck

power cable connection of the motor.Check for drain current

between the motor and the forklift housing.If the motor

connection is in good condition, the fault is in the controller

interior. Replace the controller.

02A54 LOGIC FAILURE #1 Logic card fault #1

Faults caused by under-voltage or over-voltage protection.

In 24V system, the controller detects a voltage above 45V

or below 9V; In 48V system, the controller detects a voltage

above 65V or below 11V.

Possible causes: 1. Whether there is short circuit in the

circuit system, such as DC-DC, brake coil, etc., or whether

the controller input power supply is in good contact.

2.Whether the battery voltage is over low or over high.

3.Check if the power cable above the terminals such as B+,

B, main contactor is tight.

4.Whether the calibration parameter of controller voltage is

consistent with the actual voltage.

5.Fault with the hardware circuit protected by over-voltage

on the logic card. Replace the controller.

02A55 LOGIC FAILURE #2 Logic card fault #2 Fault with the phase voltage feedback hardware circuit in

the logic card. Replace the controller.

02A56 PUMP I NO ZERO Current exceeds limit while

pump motor does not run

Replace the controller;

02A60 CAPACITOR CHARGE Capacitor charging error

With the key switch turned to “ON”, the controller will

charge the capacitor via the power resistor. The controller

will detect whether the capacitor is fully charged within the

specified time. If the capacitor is not fully charged within

the specified time, and the capacitor voltage is still less

than 20% the battery voltage, the controller will display the

warning and the main contactor will not engage.

02A61 THERMIC SENS. KO Temperature sensor fault

Controller temperature sensor output signal is outside the

range. This fault is not related to external components.

Replace the controller.

high temperature Controller overheating Measure the temperature of controller base plate.

02A62

TH.PROTECTION Controller over-temperature

protection

Lower the controller temperature to below 85oC. If the fault

still exists, possibly the temperature sensor or controller

becomes faulty. Replace the controller.

02A64 TILLER ERROR Interlock mismatches H&S

input

Replace the controller;

02A65 MOTOR TEMPERAT. Motor temperature high

1. If the motor temperature digital switch is turned on, or

analogue signal exceeds the cutout value, then the fault

results. 2. When motor temperature rises to 120 ° C, the

controller will display the warning. The forklift still can

travel but the maximum current is reduced with the forklift

performance degraded. When the motor temperature

reaches 125 ° C, the motor stops working. In this case,

action shall be taken to cool the motor. 3. The fault still

exists when the motor cools, check the line. If all have no

faults, replace the controller.

02A67

SENS MOT TEMP KO Temperature sensor fault

Symptom: Output signal of motor temperature sensor is

outside the permissible range. Solution: Check the signal

value and connection of the sensor. If they are normal, the

fault occurred in the controller.

NO CAN MSG. No CAN signal Fault with CAN communication between steering and

towing. Check CAN connection, as well as version and

configuration of software.

Loading...

Loading...