MAINTENANCE

OPERATOR MANUAL

70

EPS14P

71

OM-EPS14P2019001-EN

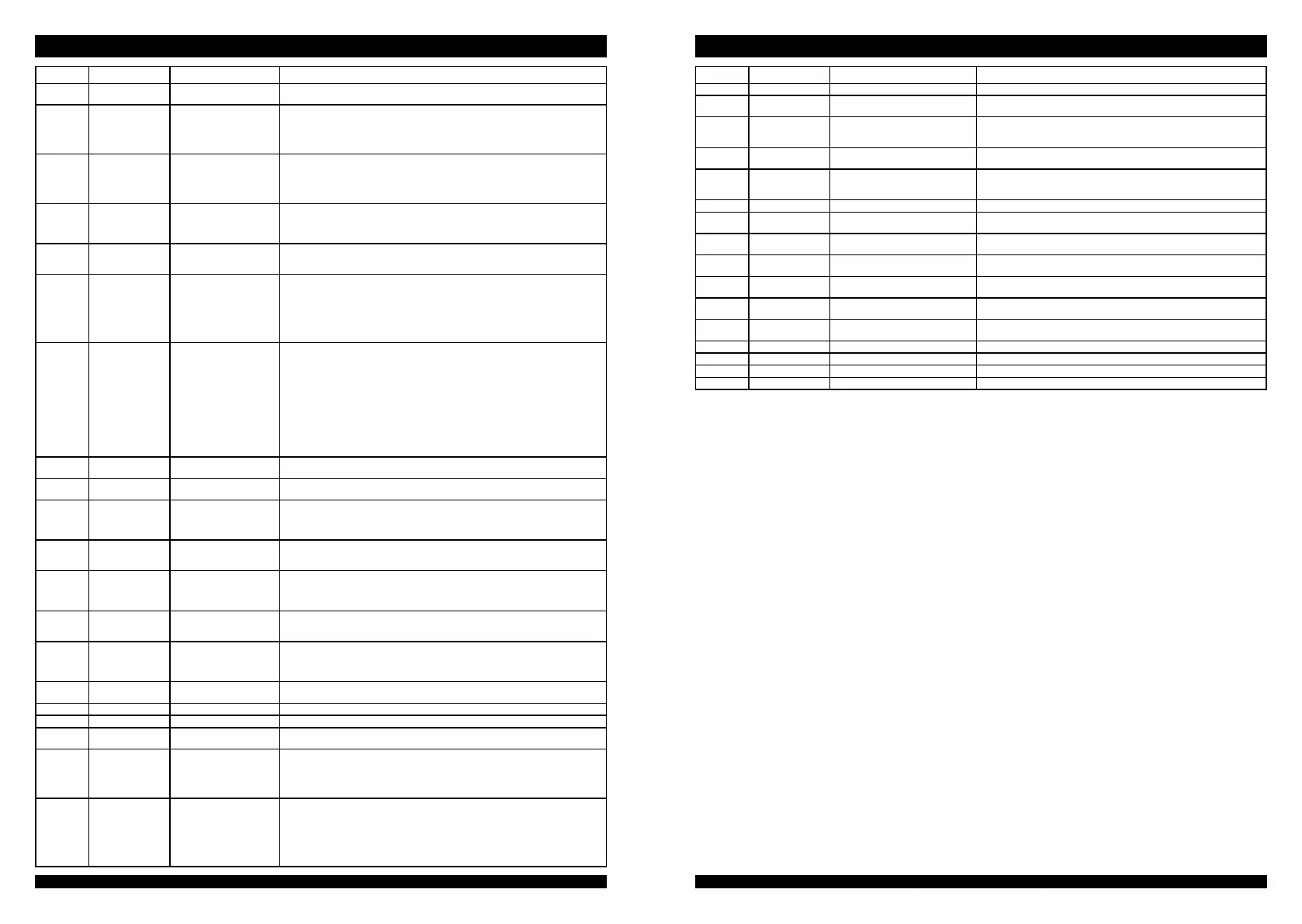

Display ALARM Fault name Recommended inspection

06A19 KM OPEN Main contactor of slave

contactor open

Slave contactor monitors the open of safety contactor of main contactor, and the

controller needs to be replaced;

06A20 MAIN CONT.OPEN Main contactor open

The coil of main contactor has been energized by the logic card, but the contactor

does not engage. Possible cause:

1.The contactor has mechanically become faulty, or its contacts get stuck

2.The contacts of contactor cannot make securely

3.If the contactor operates normally, replace the controller.

06A21 MICRO SLAVE

The information on the

status bus between the

main microprocessor and

slave microprocessor is

frozen to the OXFF value.

The controller should be replaced;

06A22 S.P OUT OF RANGE Output steering poten-

tiometer out of range

If a single potentiometer, such as CPOC1 end, is out of range 0.8V-4.2V, it will

alarm. When the dual potentiometer is selected, the sum of the two sliding ends

(CPOC1+CPOC2) is out of the range of 4.4V-5.5V and it will alarm. Check the

connection of potentiometer.

06A23 F.B OUT OF RANGE Feedback of steering motor

encoder out of range

Feedback potentiometer (CPOT connecting to CNB#6) has fault, it will alarm. The

range of CPOT is out of 0.3V-4.7V, it will alarm. Check if the steering motor encoder is

connected correctly and whether there is a open circuit;

06A24 MICRO SLAVE KO

Main and slave micro-

processor detection does

not match

1.When using a stepper motor, the direction of the stepper motor detected by the

main microprocessor and slave microprocessor is inconsistent;

2.In the closed-loop control system, the direction of the stepper motor detected by the

main contactor is incorrect and is inconsistent with the direction of the stepper motor

detected by the slave contactor;

3.The main contactor did not detect the steering limit position, but it was detected by

the slave contactor;

06A25 ENCODER ERROR Encoder fault

The controller detects that two successive speed readings of the encoder differs

greatly from each other. A normal encoder in the system cannot change speed

readings greatly within a very short time. Hence, a possible cause for the symptom is

that the wires of one or more encoders are worn or broken. Check the mechanical and

electrical parts of the encoder. Another possible for the symptom is electromagnetic

interference from the sensor bearing. If the symptom is not due to the two causes,

replace the controller.

Note: Sometimes manual operations may also cause this fault indicating on the

controller. In these cases, it is required to turn off power supply and start the forklift

again. For example:

1.The forklift suddenly collides with an obstacle so that it is incapable of travelling;

2.The driver applies the brake sharply while the forklift is travelling at a high speed

06A26 BAD ENCODER SIGN Encoder phase sequence

error

Change encoder A, B phase;

06A27 GAIN EEPROM KO EEPROM memory current

value is different

Replace the controller;

06A28 CAN BUS KO CAN BUS communica-tion

fault

1.Check if the CAN BUS communication line is connected properly;

2.Check if the bit rate of the communication is consistent;

3.Check if the CAN communication is open;

4.Check if the CAN communication loop resistance is 60Ω.

06A38 POSITION ERROR Position error 1.Check if the steering motor encoder A and B phases are loosely connected;

2.Check if the steering motor A and B phases receive interference;

06A39 SERIAL ERROR #1

Slave contactor does not

receive the information of

main contactor from serial

port

Replace the controller;

06A40 MICRO SLAVE #4 Steering motor current is

opposite to the command

direction

Replace the controller;

06A41 SLAVE COM. ERROR

Main contactor does not

receive the information of

slave contactor from serial

port

Replace the controller;

06A43 CURRENT GAIN Controller maximum current

is not controlled

Replace the controller;

06A44 CLOCK PAL NOT OK Clock error Replace the controller;

06A45 STEER SENSOR KO Dual potentiometer fault Check the wiring and output of the two-way steering potentiometer.

06A46 JERKING FB Steering potentiometer

voltage changes too much

Replace the feedback potentiometer;

06A47 FB POT LOCKED

Feedback value of steering

poten-tiometer locked

1.Check if the feedback steering potentiometer has mechanical looseness;

2.Check if there is a mechanical limit;

3.Check if the feedback steering potentiometer reaches its own limit point;

4.If the fault occurs in the opposite direction of the steering wheel during installation,

adjust the direction of the steering wheel;

06A48 MOTOR TEMPERAT. Motor temperature high

1.If the motor temperature digital switch is turned on, or analogue signal exceeds

the cutout value, then the fault results.2.When motor temperature rises to 120° C, the

controller will display the warning. The forklift still can travel but the maximum current

is reduced with the forklift performance degraded. When the motor temperature

reaches 125° C, the motor stops working. In this case, action shall be taken to cool the

motor.3.The fault still exists when the motor cools, check the line. If all have no faults,

replace the controller.

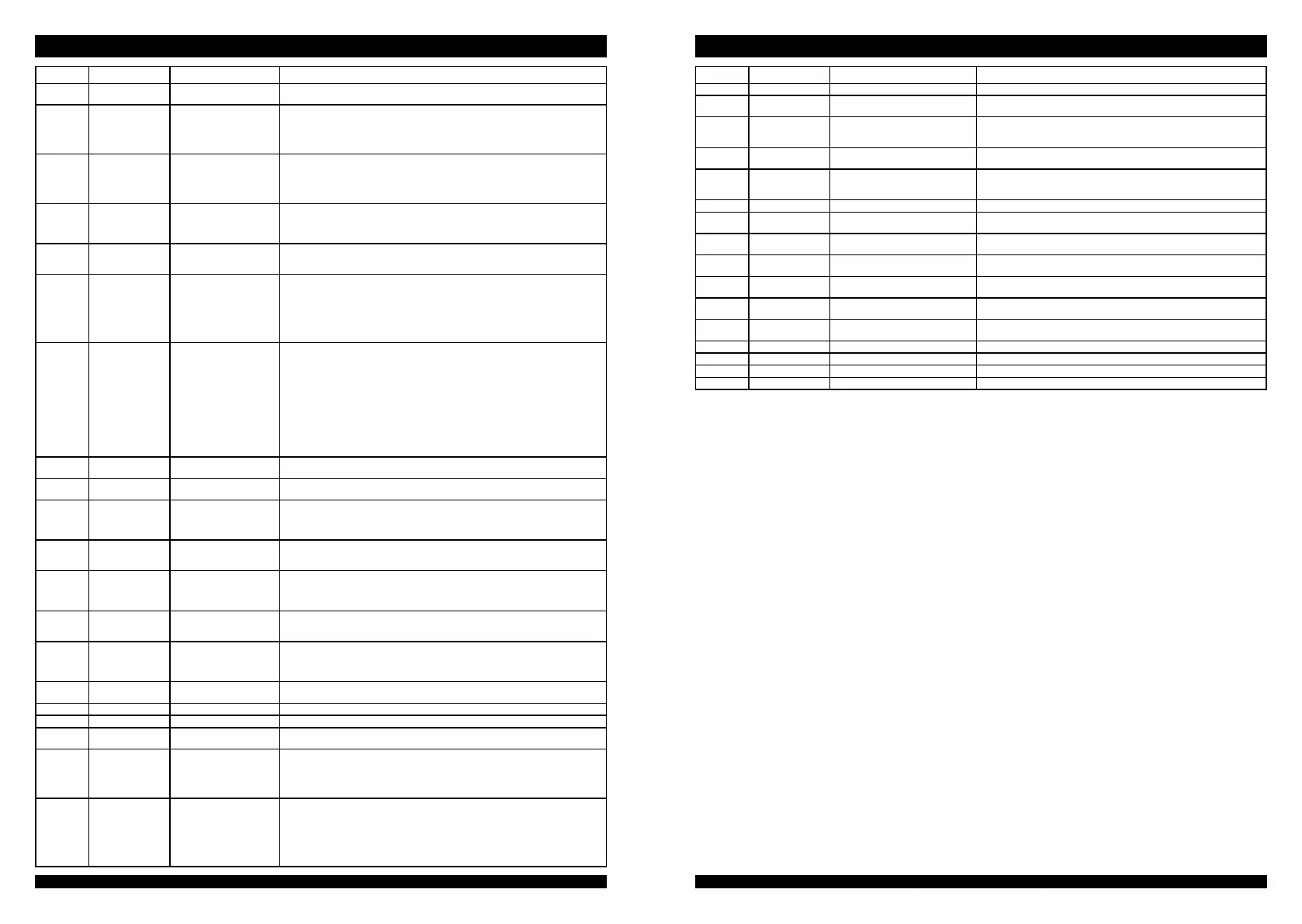

Display ALARM Fault name Recommended inspection

06A49 MOTOR LOCKED Steering motor stalling Steering motor continuous maximum current time exceeds 1s;

06A50 STEPPER MOT MISM Frequency of stepper motor Q and D

line and voltage values do not match

Replace the controller;

06A52 MICRO SLAVE #8 The encoder of the main micropro-

cessor is inconsistent with the encoder

of the slave microprocessor

Replace the controller;

06A53 INPUT ERROR #1 Advanced steering controller CAN#4

has a voltage input higher than 12V

Check if the CAN#4 cable is correct;

06A54 CAN BUS KO SL. Slave contactor does not receive any

CAN information from main con-

tactor

Replace the controller;

06A55 SL EPS NOT ALL. Self centering is not completed Replace the controller;

06A56 SL CENTERING Swing angle of self centering is out of

range

Replace the controller;

16A06 Communication fault Check the CAN cables of control handle, instrument panel, and steering

controller

17A01 battery high temp.

waring

Battery high temperature warning

17A02 battery high temp.

alarm

Battery high temperature alarm

17A03 battery leakage

waring

Battery leakage warning

17A04 battery leakage

serious

Battery leakage alarm

17A05 battery Status Alarm Battery status alarm

17A06 BDI low Battery level low (SOC ≤ 10%)

17A07 BDI low Cell voltage too low, general warn-ing

17A08 BDI low Cell voltage too low, severe warning

Loading...

Loading...