5.1 ELECTRICAL (MACHINE WIRING AND SUPPLY)

SEE FIG. 4,5, AND 6 FOR PREFERRED METHOD

The cable supplying electricity to a machine wi a given load must

increase in cross sectional area (C.S.A.) as e leng increases in order

at e voltage drop wiin e cable does not exceed recommended

limits. Cable sizing should be calculated by an appoved electrician. All

electrical work to be carried out in accordance wi I.E.E. standards,

latest issue, or local codes of practice as applicable.

The machine should be installed in accordance wi EMC2004/108/EC.

Protected supply to incorporate fuses or motor type circuit breakers

(Type C) to specified rating, (see Data Sheet). H.R.C. fuses are

recommended. An isolator which disconnects all poles must be fitted

wiin 2m and in sight of machine.†

All units must be correctly eared/grounded. An ear leakage trip of

e current operating type (30mA) is recommended to be fitted to is

heat pump and any associated equipment. When fitting recommended

ear leakage trip, to avoid nuisance tripping, e machine should be

connected to its own 30mA trip separate from any oer associated

equipment.

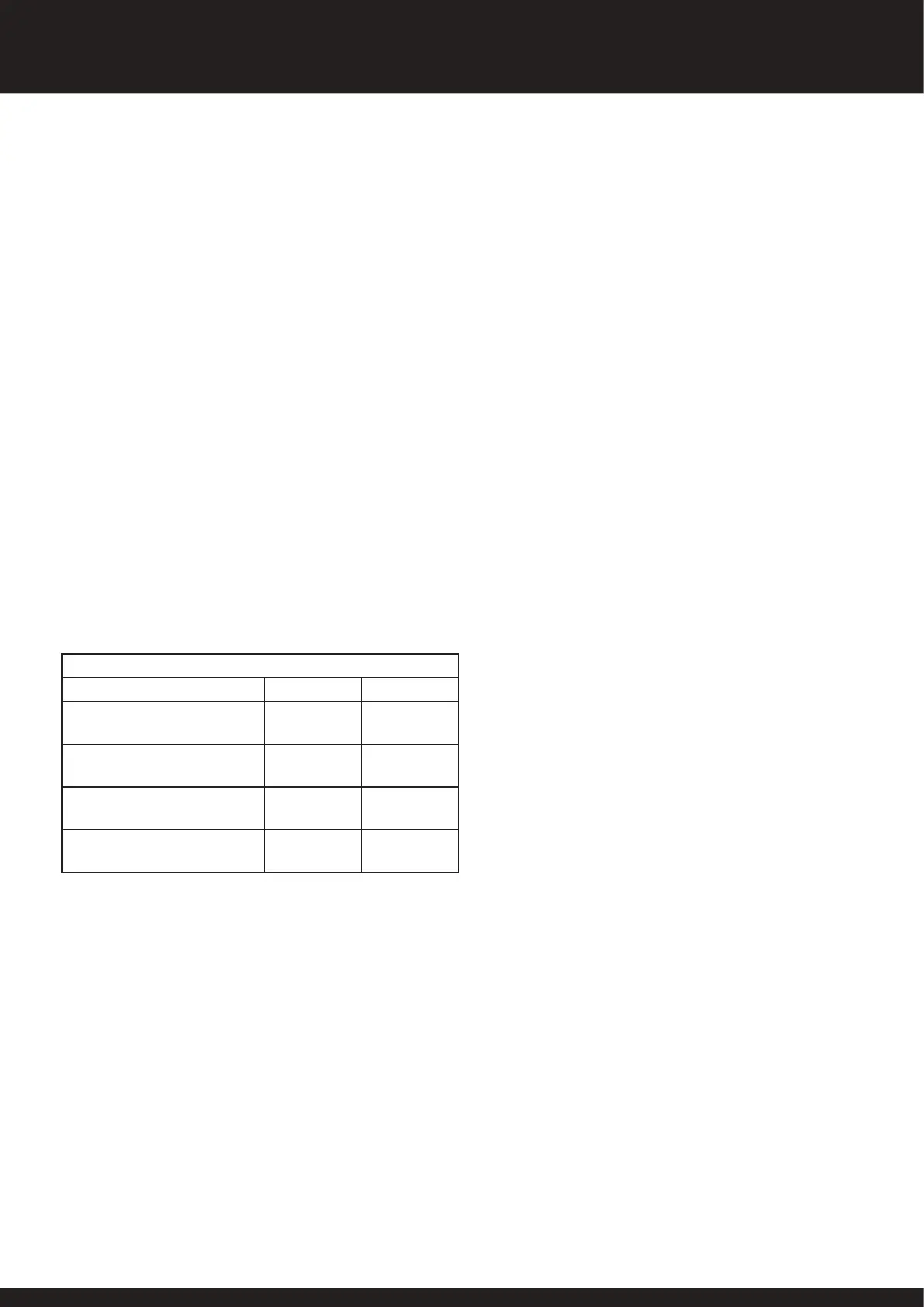

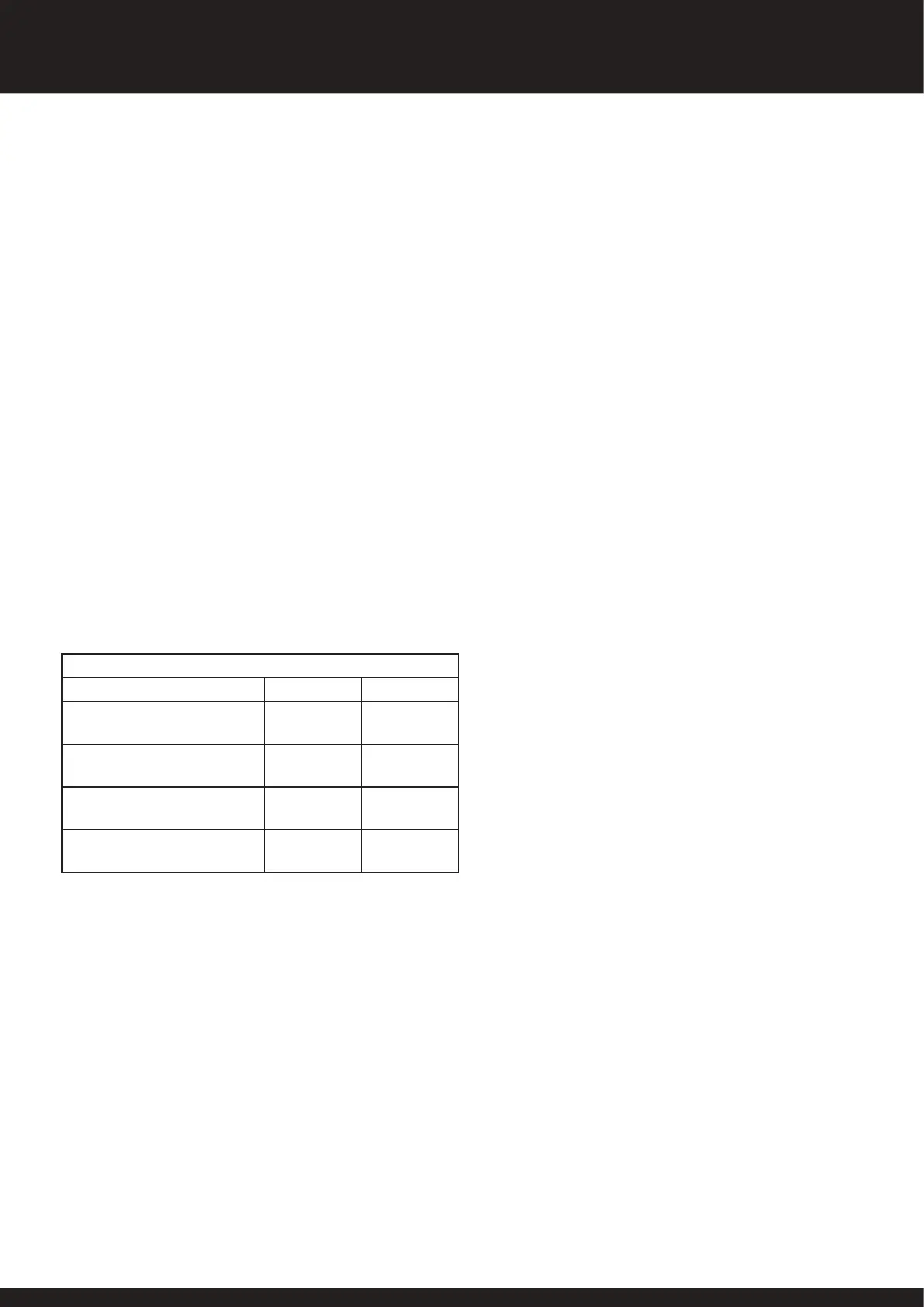

Inconsistent electrical supply

The following limits of operation must not be exceeded if Calorex

machines are to be guaranteed eier in performance or warranty

terms:

Voltage

MaximumMinimum

440V360VThree-phase machines (EU)

52.5Hz47.5HzCycle frequency (50Hz)

253V187VThree phase machines

(60Hz)

63Hz57.0HzCycle frequency (60Hz)

This voltage must be made available at e heat pump whilst running.

† Note e isolator must have a minimum of 3mm air gap when turned

off.

NOTE: All machines are fitted wi a phase protection relay and will not

run if e phases are not connected in correct order (phase sequence)

or if e supply voltage is 15% less an e nominal voltage. (415V for

3N~ 50Hz). The lamp on e phase rotation relay, situated in e electric

box, is illuminated when e phases are correctly connected and e

voltage is sucient. The undervoltage protection feature is not present

in phase protection relays fitted in 220V 3~ 60Hz machines.

When e machine is started for e first time it is vital at e 12 hour

delay incorporated into e compressor is allowed to occur. This delay

prevents damage to e compressor which would be expensive to

repair. Aer is initial start up e machine can be turned on and off by

use of e standby switch. It should be noted however at when on

standby e machine is still live.

12

SD566252 ISSUE 51

PR0-PAC SYSTEM OWNER INSTALLATION MANUAL

Loading...

Loading...