EN

Page 16 / 96 E-MXAM E-MXPM E-NGXM Rev6 - Operating Instructions

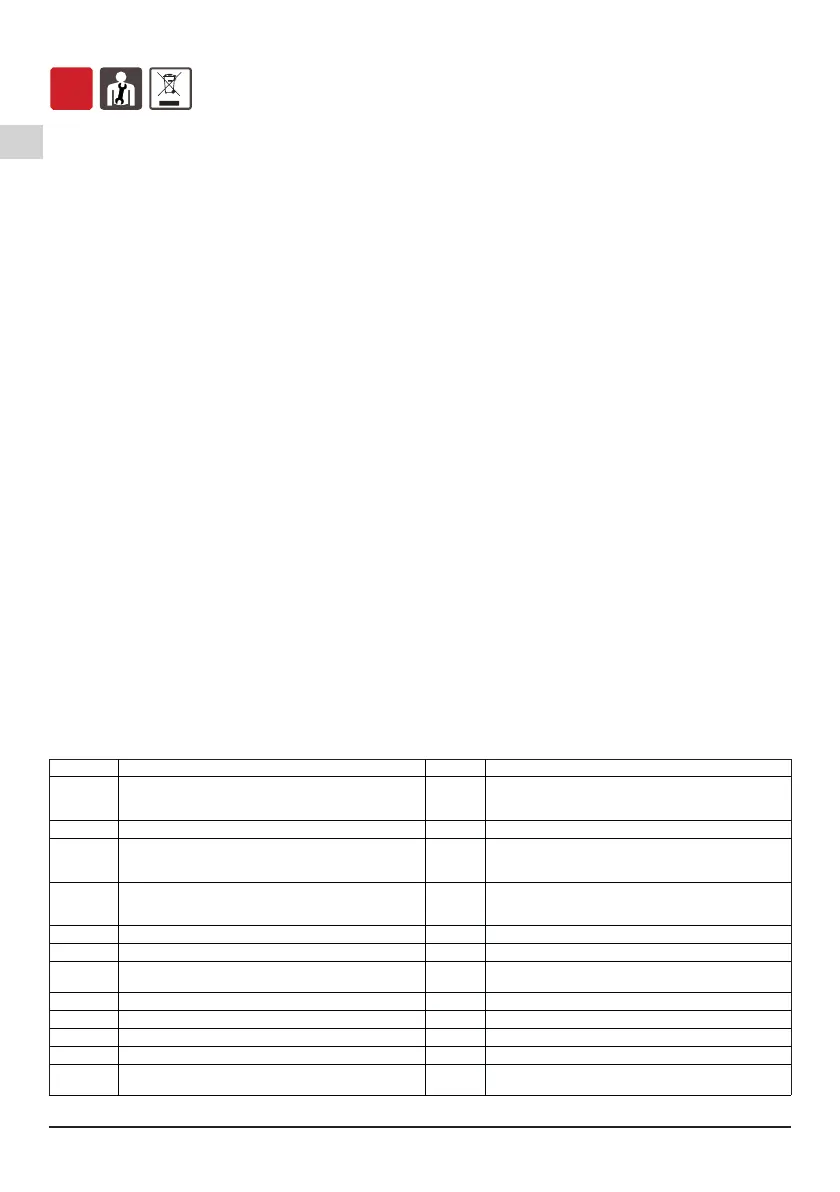

12. ALARMS

Error reset can be automatic or manual, depending on the error that occurs. Manual reset is carried out using the

enter button and then start to restart the pump.

Code Description

Reset ERR

Causes

Er01 Blockage due to no water MAN

The device is in failure due to no water.

The system try to restart automatically and make one

attempt every 10 minutes for 7 times.

Er02 Faulty pressure sensor – Max. ressure exceeded MAN Faulty pressure sensor

Er03 Blockage due to low supply voltage AUT

Supply voltage lower than 192V.

- The system automatically restart when the clamp

voltage is higher than 200V.

Er04 Blockage due to high rectied voltage AUT

Supply voltage higher than 225V.

- The system automatically restart when the clamp

voltage is lower than 225V.

Er05 Blockage due to exceeded of number of starts MAN The system has started more than 240 times in 2 hours

Er06 Blockage due to overpower in the electro pump MAN

Er07 Blockage due to overcurrent in the electro pump motor MAN

The system try to restart automatically and make one

attempt every 10 seconds for 3 times.

Er08 Blockage due to internal overheating AUT

Er09 Blockage due to overpressure MAN

Er10 Thermal-protector intervention detected MAN Motor overheating

Er11 Internal hardware error AUT

Er12 Low pressure failure MAN

Pressure lower than UP02 parameter for more than 3

hours with pump run-ning

10. DISPOSAL

OFF

European Directive

2012/19/EU (WEEE)

The nal disposal of the device must be done by

specialized company.

Make sure the specialized company follows the

classication of the material parts for the separation.

Observe the local regulations and dispose the device

accordingly with the international rules for environment

protection.

11. SPARE PARTS

11.1. Spare-parts request

When ordering spare parts, please quote their

designation, position number in the cross section

drawing and rated data from the pump name plate

(type, date and serial number).

The spare parts request shall be sent to CALPEDA

S.p.A. by phone, fax, e-mail.

11.2. ESIGNATION OF PARTS

Nr. Designation

14.00 Pump casing

14.04 Plug

14.06 O-ring

14.12 Plug

14.16 O-ring

14.20 O-ring

14.24 Screw

14.47 O-ring

14.64 Valve, set

14.66 Washer / Retaining ring

16.00 Suction casing

16.14 Plunger

16.15 Spring

16.16 O-ring

16.17 Valve

20.00 Delivery casing

22.00 Ejector

22.12 O-ring

22.16 O-ring

25.01 First stage casing

25.02 Stage casing (complete)

25.05 Last stage casing

25.10 Washer for missing impeller

25.11 First stage spacer

26.00 Diffuser

26.06 O-ring

28.00 Impeller

28.04 Impeller nut

28.08 Washer

28.12 Circlip

34.00 Casing cover

36.00 Mechanical seal

36.51 Retaining ring, split

36.52 Shoulder ring

46.00 Deector

64.15 Spacer sleeve

70.00 Lantern bracket

73.00 Ball bearing

76.00 Motor casing with winding

76.04 Cable gland

76.16 Support

76.54 Terminal box, set

78.00 Shaft with rotor packet

81.00 Ball bearing

82.00 Motor end shield

82.04 Compensating spring

88.00 Motor fan

90.00 Fan cover

90.04 Screw

92.00 Tie-bolt

94.00 Capacitor

94.02 Capacitor gland

98.00 Terminal box cover

98.04 Screw

98.08 Gasket

98.20 Screw

98.51 Transducer

98.52 Signals cable

98.53 Main power cable

98.55 Terminal box cover with board

E-MXAM E-MXPM E-NGXM Rev6.indd 16E-MXAM E-MXPM E-NGXM Rev6.indd 16 02/02/22 14:3502/02/22 14:35

Loading...

Loading...