EN

I-MAT_Ed6 - Operating Instructions Page 51 / 164

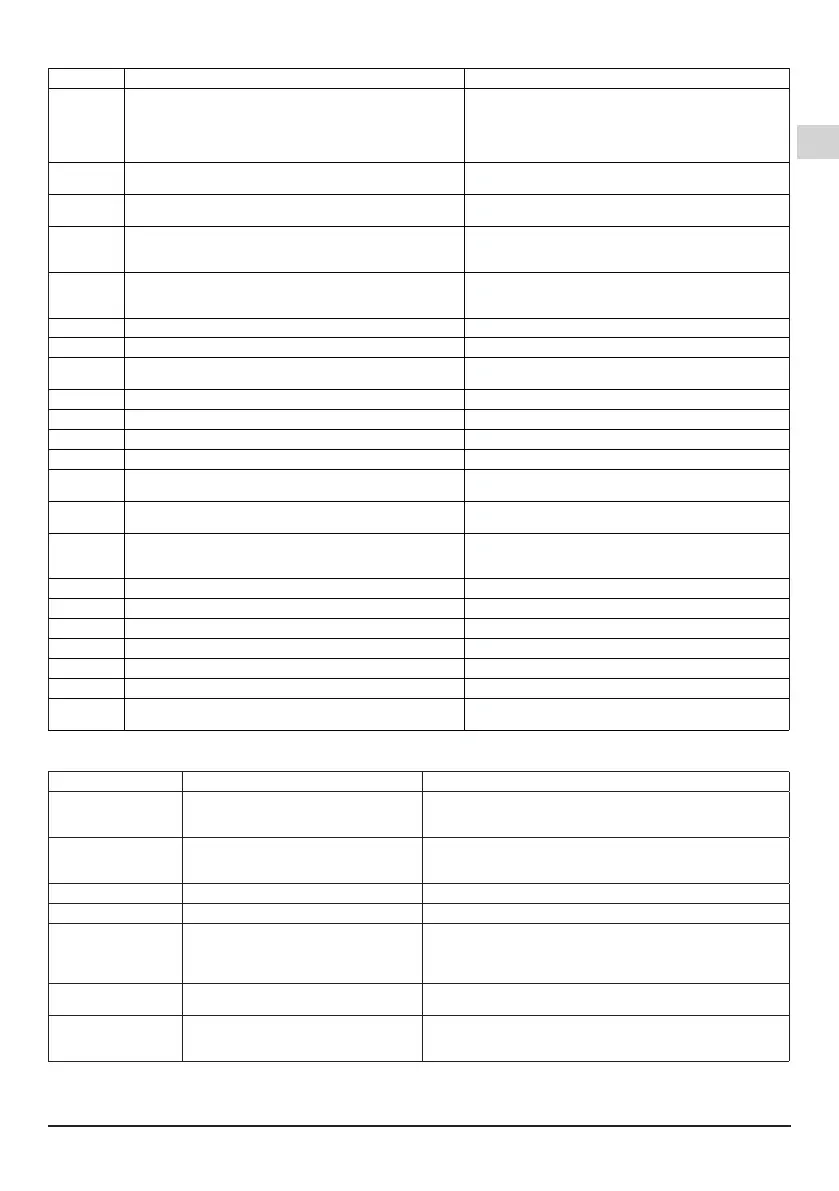

17. Alarms

Code Description

Causes

Er01

Blockage due to no water;

Failed to reach set-point.

No water in the suction tank.

The system stops and restarts itself automatically:

- One attempt every 10 minutes for 6 times

- One attempt every hour for 24 times

- One attempt every 24 hours for 30 times

Er02 Primary pressure transducer fault

Cable not connected, broken connection, transducer

faulty.

Er03 Secondary pressure transducer fault

Cable not connected, broken connection, transducer

faulty.

Er04 Blockage due to low supply voltage

Supply voltage lower than 330V

- The system automatically restart when the clamp

voltage is higher than 345V.

Er05 Blockage due to high rectied supply voltage

Supply voltage higher than 520V

- The system automatically restart when the clamp

voltage is lower than 520V.

Er06 Blockage due to overcurrent in the electro pump motor

Er07 Blockage due to unbalanced output phases

Er08

Blockage due to direct short circuit between the phases

of output terminals

Er09 Blockage due to missing output phases

Er10 Blockage due to internal overheating

Er11 Blockage due to overheating of the power module

Er12 Blockage due to exceeded of number of starts

Er13

Blockage due to missing/wrong setting of main

parameters

Er14 Blockage due to oat switch 1 intervention

The system will restart after a time, dened in parameter

AP41, from the state variation of the oat switch.

Er15 Blockage due to oat switch 2 intervention

The system will restart after a time, dened in

parameter AP43, from the state variation of the oat

switch.

Er16 Internal Hardware error Contact the technical assistance.

Er17 Not implemented

Er18 Cascade mode communication error Check the RS485 connection.

Er19 Cascade expansion card failure Cascade expansion card not connected or faulty

Er20 Blockage due to low voltage 24 V

Er21 Fieldbus expansion card failure Cascade expansion card not connected or faulty

Er22 Fielbus communication failure

Check the MODBUS connection and the devices in

the network

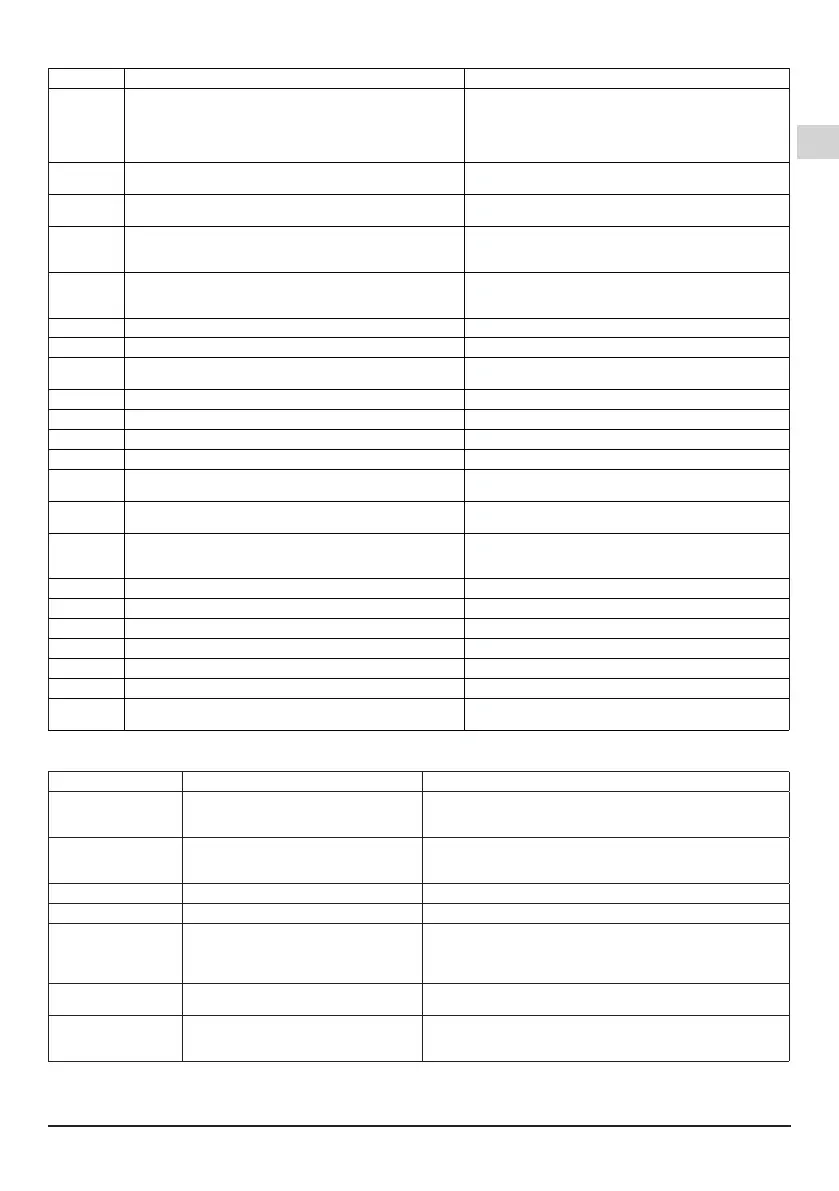

18. Troubleshooting chart

Fault Probable cause Possible solution

Short-circuit - Motor or cable short-circuit

- Wrong power supply connection

- Wrong connection of the cable shield

- Check motor connections

- Check power supply voltage

Frequency

converter

overheating

- Ambient temperature too high

- One or more frequency converter fans

faulty

- Check the condition of installation (see section 3.1)

- Change the defective fans

Low supply voltage - Supply voltage lower than 330V - Check the supply line

High supply voltage - Supply voltage higher than 520V - Check the supply line

Overcurrent - Step up/down ramp too high

- Improper connection of the motor

- Wrong motor settings

- Increase the time of the ramps (see section 16.2)

- Check the parameters of the motor (see section 16.1)

- Check the frequency converter settings and motor data (see

section 16.1)

Electronic card

overheating

Electronic card overheating - Check the condition of installation (see section 3.1)

- Reduce the carrier frequency

Dry-run The pump is running with no water - Check the suction and delivery manifold and the priming

conditions

- Check the performances curves of the pump

1) For electrical reparation, disconnect the supply voltage from the frequency converter. Refer to the safety

regulation described in section 4.

I-MAT_Ed6.indd 51I-MAT_Ed6.indd 51 18/11/20 08:2118/11/20 08:21

Loading...

Loading...