Pagina 11 / 64NG,NGL,NGX Rev. 7 - Operating Instructions

EN

8.2 Dismantling the system

Close the suction and delivery gate valves and drain the

pump casing before dismantling the pump.

8.3 Pumps with IP 55 protection (Special construction)

To always assure IP 55 degree of protection, it is necessary

to check the following points:

- Before starting the motors, carefully control the position of

the gasket between terminal box and its cover. For cable

of small size, use a protective covering between cable and

cable gland.

-

When disassembling the end shields of the motors,

restore the existing joint using the sealing glue LOCTI-

TE type 510 or other equivalent sealing system, if any,

and check the perfect assembly of the sealing ring on

the shaft.

9. DISPOSAL

European Directive

2012/19/EU (WEEE)

The final disposal of the device must be done by speciali-

zed company.

Make sure the specialized company follows the classifi-

cation of the material parts for the separation.

Observe the local regulations and dispose the device

accordingly with the international rules for environment

protection.

10 SPARE PARTS

10.1 Spare-parts request

When ordering spare parts, please quote their designa-

tion, position number in the cross section drawing and

rated data from the pump name plate (type, date and

serial number).

The spare parts request shall be sent to CALPEDA

S.p.A. by phone, fax, e-mail.

Changes reserved.

OFF

OFF

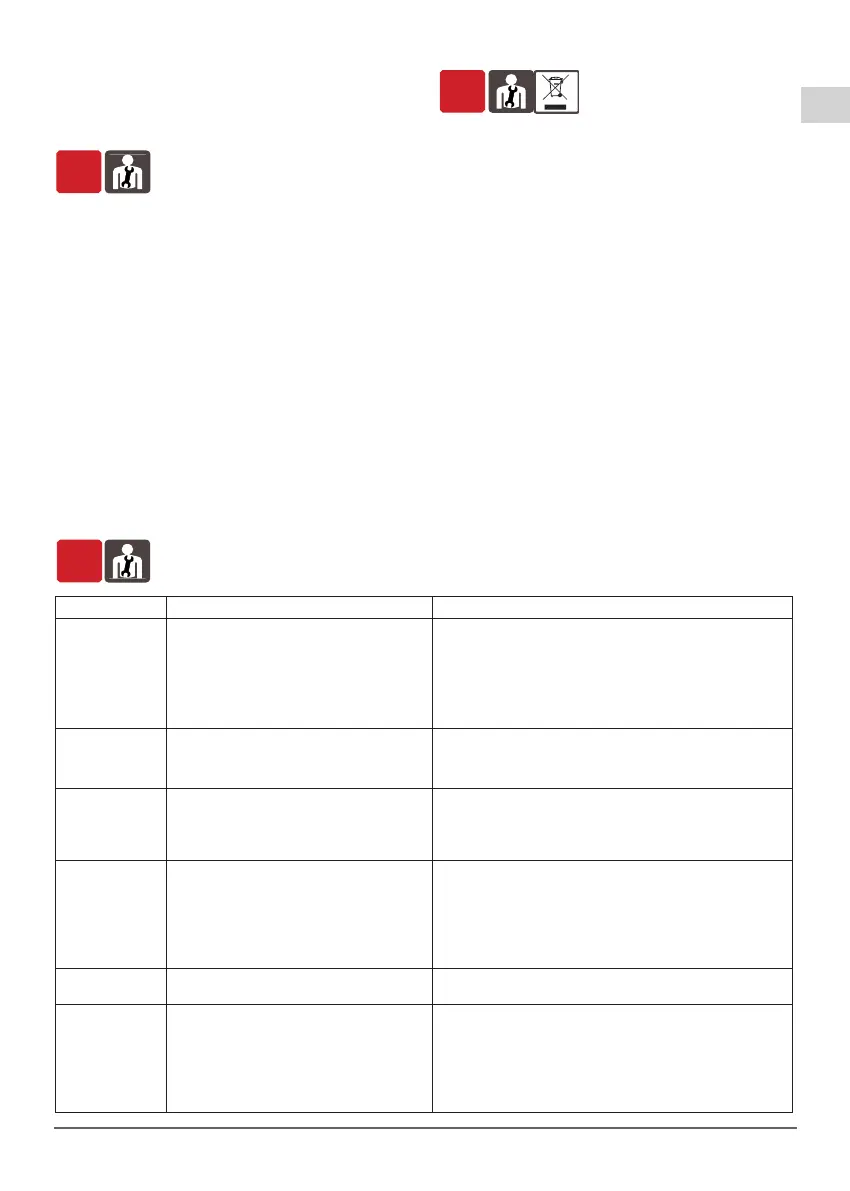

11. Troubleshooting

WARNING: Turn off the power supply before performing any operations.

Do not allow the pump or motor to run when dry even for a short period.

Strictly follow the user instructions and if necessary contact an authorised service centre.

OFF

PROBLEM

1) The motor does

not start

2) Pump blocked

3)The pump func-

tions but no water

comes out

4) Insufficient flow

5)

Noise and vibrations

from the pump

6) Leakage from the

mechanical seal

PROBABLE CAUSES

1a) Unsuitable power supply

1b) Incorrect electrical connections

1c) Engine overload protective device cuts in.

1d) Blown or defective fuses

1e) Shaft blocked

1f) Motor failed

2a) Prolonged periods of inactivity .

2b) Presence of solid bodies in the impeller

2c) Bearings siezed

3a) Presence of air inside the pump or suction pipe

3b) Possible infiltration of air.

3c) Foot valve blocked or suction pipe not fully

immersed in liquid

3d) Suction filter blocked

4a) Pipes and accessories with diameter too small

4b) Presence of deposits or solid bodies in the

impeller

4c) Rotor deteriorated

4d) Worn rotor and pump case

4e) Gases dissolved in the water

4f) Excessive viscosity of the liquid pumped

4g) Incorrect direction of rotation

5a) Worn bearings

5b) Unbalanced power supply

6a) The mechanical seal has functioned when dry or

has stuck

6b) Mechanical seal scored by presence of abrasive

parts in the liquid pumped

6c) Mechanical seal unsuitable for the type of

application

6d) Slight initial drip during filling or on first start-up

POSSIBLE REMEDIES

1a) Check that the mains frequency and voltage are suitable.

1b) Connect the power supply cable correctly. Check the setting of the

thermal overload protection.

1c) Check the power supply and make sure that the pump shaft is

turning freely. Check the setting of the thermal overload protection.

1d) Replace the fuses, check points a) and c)

1e)

See “Blocked pump” instruction booklet

1f) Repair or replace the engine.

2a) Unblock the pump by using a screw driver to turn the relevant notch

on the back of the shaft.

2b) Remove any solid foreign bodies inside the impeller

2c) Replace the bearings.

3a) Release the air from the pump using the delivery control valve.

3b) Check which part is not tight and seal the connection.

3c) Clean or replace the bottom valve and use a suitable suction pipe .

3d) Clean the filter, if necessary, replace it . See point 2b) also.

4a) Use pipes and accessories suitable for the specific application

4b) Clean the impeller and install a suction filter

4c) Replace the impeller

4d) Replace the impeller and the pump casing

4e) Perform the opening and closing manoeuvres through the feeder

gate

4f) The pump is unsuitable

4g) Invert the electrical connections in the terminal board

5a) Replace the bearings

5b) Check that the mains voltage is right

In cases 6a), 6b) and 6c), replace the seal

6a) Make sure that the pump casing is full of liquid and that all the air has

been expelled.

6b) Install a suction filter and use a seal suited to the characteristics of

the liquid being pumped.

6c) Choose a seal with characteristics suitable for the specific application

6d) Wait for the seal to adjust to the rotation of the shaft. If the problem

persists, see points 6a), 6b) or 6c).

IST NG_NGX_NGL REV7 05_2021.qxp_MXS 11_03con gall 24/05/21 09:58 Pagina 11

Loading...

Loading...