CandCNC

Page 24

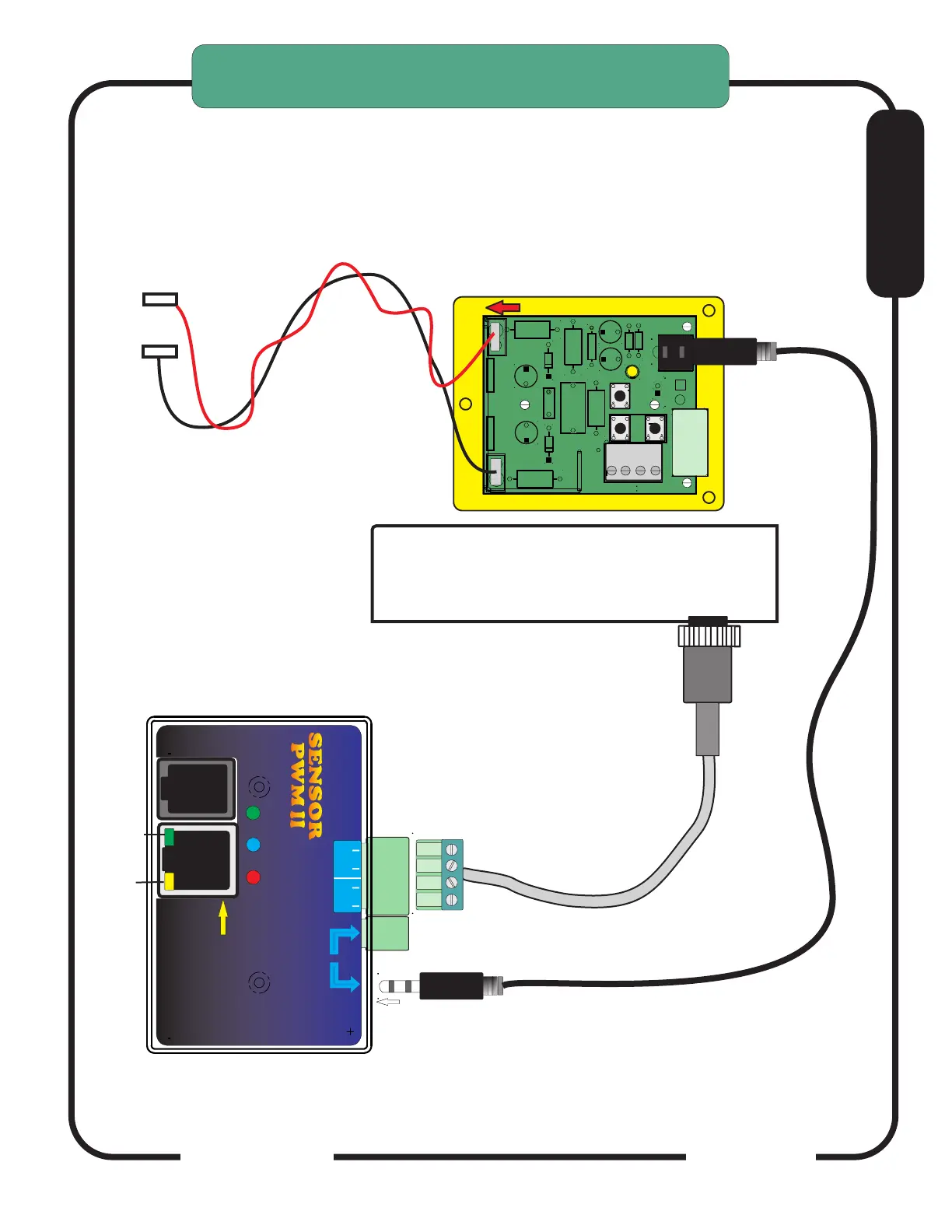

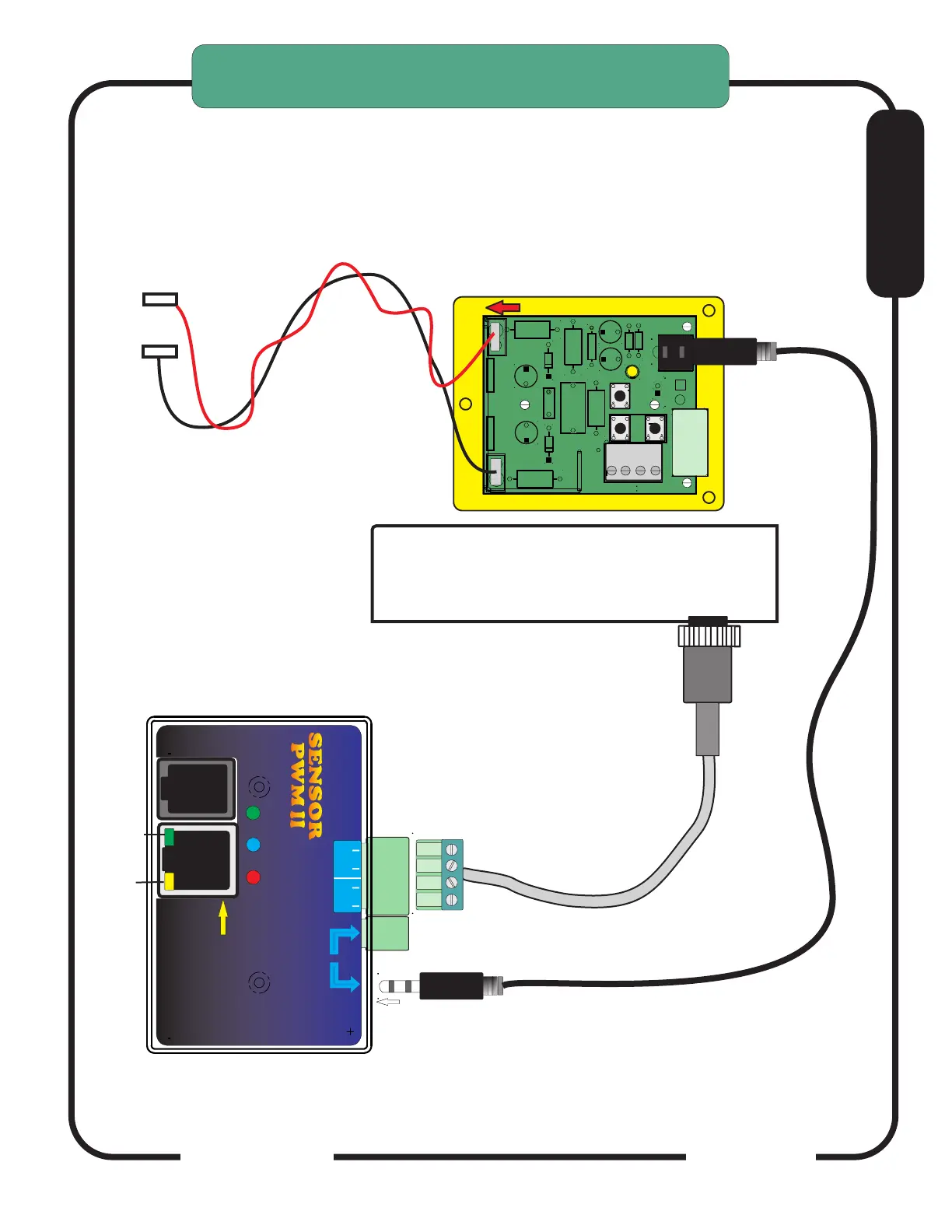

HYPERTHERM 1000/1250/1650 and Thermal Dynamics units

with rear CPC connector and no Arc Voltage Divider

F

ARC

OK

TORCH

SWITCH

TO THC SENSOR PWM

MODULE use CCAB-31

Volts

3

Tip

Volts

4

+

-

THC

J14

2

TP1

TP2

REV 18

J15

HIGH VOLTAGE

Electrode

D13

C1

Tip

1

SW1

CAUTION!

HIGH VOLTAGE

L2

- [NEG]

Volts

R1

PLASMA

CAUTION!

1

CandCNC

VOUT

HIGH VOLTAGE

R6

CAUTION!

ARC OK

Out

Divided

+ [POS]

Workclamp

CAUTION

TO THC SENSOR PWM

TORCH SWITCH

Volts

Divided

Volts

ARC OK

1

TORCH SWITCH

1

SW3

PICKUP

-

J5

1

SW2

1

TORCH FIRE

TORCH

+

+

-

WHEN TORCH is ON

FIRES

MANUAL

1

Local Connections

TO WORKCLAMP

CONNECTION (+)

TO ELECTRODE

CONNECTION (-)

CAUTION: High Voltages Present

When TORCH is ON.

CAUTION: High Voltages Present

When TORCH is ON.

SAC-01 Shieilded Cable

to Torch Sensor PWM

Module

Use 18 or 20ga insulated hookup wire.

Insulation rating to 400V minimum.

+

-

Divided volts from

CandCNC Raw Arc

Volts card

METHOD TO CONNECT TO UNIT

WITH MACHINE TORCH USING

REAR CPC CONNECTOR FOR

TORCH FIRING AND ARC OK

OPTIONAL RAV-02

MOUNTED INSIDE PLASMA

MIC-02

For units with CPC but NO

Internal Voltage Divider

1

TO CPC CONNECTOR ON REAR

OF PLASMA

Route shielded cable

through rear bulkhead

Raw arc volts connection points

vary from one model to another.

Refer to manufacturers manuals

for locations.

Digital Plasma

Module

Torch

Volts IN

ON

ACT

+5

To DCP-01

To DTHC

Module

ARC OK

To Plasma

Cable

Input JACK

Divided Volts

CandCNC

Front

Arc OK

+12 PWR

T

o CPC or RAV-02

Arc OK

(Transfer)

TORCH

SWITCH

SENSORSENSOR

PWM PWM

IIII

Loading...

Loading...