10

pulse lasting for 0.05 seconds. The duty cycle is set for 50%

so you will have 1 energy pulse with 1 period of rest with no

energy between each pulse. If the laser is producing energy

at 1 pulse per second for 0.5 seconds per pulse, you will be

producing energy for a total of 0.5 seconds. The result will be

an average energy per second that will be 50% of what you

have set the laser for. Therefore, when using pulsed energy,

you will have to adjust your power upward in order to achieve

the same rate of work as the same power set in . Two Watts

of Pulsed energy will be the same average power output

as 1 Watt . Remove your foot from the foot pedal and use

a clean 2 x 2 gauze sponge moistened with water to remove

debris from the ber tip. Do not use ammable liquids to wet

the sponge. Place the laser in Standby mode by turning

“Ready” off until you are ready to start another procedure.

Tissue Responses to Laser Energy: Maximum results will be

achieved by regulating the power and the speed that the

operator moves the ber tip. Tissue charring is an undesirable

after effect of too much power or the tip moving too slowly.

Always use the least amount of power necessary to complete

your procedure. The ideal tissue response will show little or no

discoloration after lasing and there will be less residual damage

and faster healing. Avoid penetrating or damaging the

periosteum and do not use the laser on alveolar bone. Because

the laser energy is attracted to melanin and hemoglobin,

power must be reduced when treating patients with darker

soft tissue. Always begin lasing with the lowest power you can

use to remove or modify the target tissues. Avoid damage to

the gingival sulcus by moving the ber tip quickly and using

low power settings. Check to make sure you have a good

cleave of the ber so that no shard is present on the tip. A

shard may act as a miniature scalpel and damage the small

blood vessels, thus preventing hemostasis and coagulation.

3.2.3 After Each Procedure

•

Cleave used ber tip and discard in suitable biowaste disposal.

•

Wipe the outside of the ber using a disinfectant or sterilization

solution and then retract the ber by depressing the RETRACT

button on the control panel. Do not retract the distal end of

the ber into the cartridge.

•

Turn the key to the off position if you are not going to be

starting another procedure and remove key.

•

Record the Powers and Total Lasing Times used for each

procedure in the patient’s chart.

Example:

Patient Name Mary Jones

Procedure Gingivectomy #6 and #7

#6 Lasing time

90 seconds @ 2.0 Watts

air cooled

#7 Lasing time

60 seconds @ 1.5 Watts

air/water spray

SECTION 4: PREPARATIONS, CARE,

AND MAINTENANCE

The ber optic element of a laser is responsible for carrying the light

from the diode array to the tissue being treated. The dental laser

bers are usually made of quartz, sapphire, silica or a combination

of those elements. Quartz/silica is the most popular product used

in diode lasers. Be advised about the potential hazards when

inserting, steeply bending or improperly securing the ber optics to

the chassis. Laser radiation exposure may occur in these instances

which could be harmful to yourself, your staff, and your patient.

Special care should be taken not to break or snap the ber.

As the Aiming Beam passes down the same delivery system as the

Working Beam, it provides a good method of checking for integrity

of the delivery system. If the aiming beam spot is not present at

the distal end of the delivery system, its intensity is reduced or it

looks diffused, this is a possible indication of a damaged or an

inproperly working delivery system.

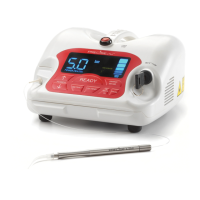

4.0 DISPOSABLE FIBER CARTRIDGE

The ber cartridge is a removable assembly with a plug-in

capability that provides power for the internal retraction device.

This cartridge is disposable after all ber has been used. This

cartridge is not autoclavable.

4.0.1 Replacing the Fiber Cartridge

A white mark on the ber indicates 6’ of ber remaining on the

cartridge. At this point, a new ber cartridge should be ordered.

When the cartridge is empty, it should be released from the laser

aperture and gently removed. Slowly slide the cartridge out to

the left using the dovetail as a guide. The ber cartridge can be

thrown away.

Note: Retain the ber end cap. DO NOT discard the end cap.

4.0.2 Fiber Preparation

Using the EXTEND button on the control panel, press the button

to extend (toward the front of the laser) the ber. Extend 3 - 4’ of

ber and feed it through the ber locking collar after you have

loosened the collar. The ber should extend about 1’ beyond the

distal end of the handpiece so that you can strip the ber and

place the disposable tip.

Do not continue to use the ber tip once you have observed that

the tip has a blackened appearance that is greater in length

than 2 - 4 mm from the previous cleave spot. The protein debris

of gingival tissue accumulates on the tip during surgery and

retains extreme heat that can cause rapid tip deterioration and

subsequent breakage. This is especially important when using the

laser for periodontal pocket debridement. During surgery, clean

the tip often using a 2 x 2 sponge moistened with water. Do not

use alcohol or other combustible liquids to moisten the 2 x 2 gauze

sponge and do not use the sponge while the tip is hot. Always use

a cold disinfectant solution like BIREX® or CIDEX® to wipe off the

ber jacket before retracting the ber. The ber can be advanced

or retracted by using the retract and extend buttons on the front

control panel.

The ber cartridge is a removable assembly with a plug-

in capability that provides power for the internal retraction

device. This cartridge is disposable after all ber has been used.

This cartridge is not autoclavable. The ber cartridge contains

approximately 20’ (6 meters +) and is wound onto a spool. The

ber itself has three components:

• Jacket

• Cladding

• 400 micron quartz/silica ber

4.0.3 Jacket

This is the protective cover for the ber system and usually is made

of a synthetic material that is clear or white in color. There can be

Loading...

Loading...