12

Additionally, the tip can transfer heat up the shaft of the ber to the

edge of the jacket which may melt slightly. After your procedure,

always cleave the blackened tip and strip the damaged jacket.

Wipe the jacket down using BIREX® CIDEX® or a comparable

product that can disinfect the jacket. Dry the jacket using a clean

2 x 2 sponge prior to retracting the ber into the ber cartridge.

Also see section 6.0 on page 15.

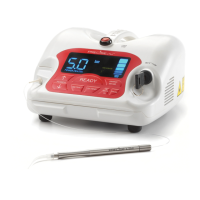

4.1 LASER MAINTENANCE

4.1.1 Laser Chassis Disinfection

The exterior of the laser should be cleaned using a liquid

disinfectant similar to BIREX® or CIDEX®. Do not spray the

disinfectant directly on the chassis. Apply with a gauze sponge

or wipe. Do not use abrasive materials to clean the system. Place

a barrier material similar to cellophane over the control panel and

LED screen prior to treating the next patient.

4.1.2 Calibration

The Precise® LTM Laser uses solid-state circuitry to continuously

monitor the power output and adjusts the power supplied to

the laser module to keep the output consistent with the user

dened setting. If output levels are more than ± 20% of the set

value, the unit is designed to shut down power to the laser, and

an audible alarm will sound. If this happens, the unit should be

turned off and allowed to sit for 5 minutes and turned on again.

If the laser then boots without beeping, the microprocessor has

been able to make operational adjustments and the unit will

perform its functions. If, upon restart, the unit continues to beep,

the unit will need to be sent in for adjustment by CAO Group,

Inc., Service Department. We suggest that your practice establish

an internal calibration program for your laser. Recalibration is

recommended at a minimum of once per year based on average

usage. Recalibration may be performed by the manufacturer by

returning the unit. Alternatively, you may purchase a calibrated

hand -held power meter approved for use with 810 nm devices to

check power output. The laser should be set at 1, 3, and 5 Watts

with output checked at each level. The output display should be

within 20% of the meter reading. If not, recleave the ber and

re-check. If the output display is still outside the 20% tolerance,

return the unit to the manufacturer for recalibration. There are

no methods available for the user to adjust the calibration of the

unit and the unit must not be adjusted by the user for any reason.

4.1.3 Handpiece Preparation

The Precise® LTM handpiece is designed for easy assembly and

then sterilization after each patient.

The handpiece has four (4) components:

a. Fiber locking cap (See Figure 33)

b. Plastic collet - located inside ber locking cap (See Figure 34)

c. Body (See Figure 35)

d. Disposable tip - discard after each patient; not

autoclavable (See Figure 36)

Assemble the handpiece with plastic collet, Fiber Locking Cap and

disposable tip in place; only lightly tighten the the Locking Cap

onto the handpiece body. Extend the ber about 3-4’ from the

Precise unit. Slide the end of the ber through the Fiber Locking

Cap, through the handpiece and out the disposable tip so that

about 2-3” of ber extends out of the handpiece. Firmly tighten

the Fiber Locking Cap so that the ber is held securely in place.

Now the ber can be prepared for lasing (Section 4.1.4).

The Precise® LTM uses an autoclavable stainless steel handpiece

that should be sterilized after every patient. Clean the handpiece

with warm soapy water; rinse thoroughly; disassemble; place in

an autoclavable bag, and then autoclave it accordingly.

Note: Do not re working laser if handpiece is not properly attached

to ber.

4.1.4 Preparation for Lasing

Using your stripper, remove approximately 1/4” - 3/8” of jacket

from the distal end of the ber. Cleave the ber and examine the

results by turning the laser to the Ready status. The aiming beam

should create a near perfect circle when directed onto a white

surface from about 1/4” - 3/8” above the paper. (See Figures 27

through 32). Once cleaved, the ber tip should be disinfected

(See Section 4.0.9).

4.1.5 Disposable Tips

The disposable tips can be shaped to provide the clinician two (2)

degrees of access required, straight and 60° curved.

Note: Disposable tips are single use, not autoclaveable.

Figure 33 - Fiber locking cap Figure 34 - Plastic collet

Figure 35 - Body Figure 36 - Disposable straight

tip (60° angle disposable tip

also available)

Figure 37 - Handpeice Assembly

Loading...

Loading...