7

people including the patient, present in the treatment area

during lasing.

• Safety Eyewear: While using the Precise® LTM laser, doctors,

auxiliary staff, patients, and anyone attending them in the

operatory must wear the laser glasses provided with the

Precise® LTM system, which is appropriate for use with this

type of device. If additional glasses are obtained, they must

have the same specications for wavelength and optical

density as the glasses provided with this equipment. Never

point the laser tip directly at the face, eyes or skin of anyone

while emitting energy. The aiming beam is also capable of

causing eye damage.

• Test Firing the Laser: Always test-re the Precise® LTM prior to

using it intra-orally. Using a power of 1 Watt continuous wave

or less, place the laser in the ready mode. Then, activate

the laser for 1 - 2 seconds while aiming the ber onto a 2 x 2

gauze sponge moistened with water. Do not use alcohol or

any other combustible material to moisten the 2 x 2 sponge

as it may ignite.

•

Fiber Preparations: After cleaving and stripping the ber,

photo-initiation of the ber tip will allow the operator to remove

tissue more rapidly when contact procedures are indicated.

Gingival debris on the tip will retain the heat and it should be

removed. The tip will also begin to blacken and deteriorate

as it retains the heated debris and can break if not removed

by cleaving it. Clean the tip often using a 2 x 2 gauze sponge

moistened with water. Do not use combustible liquids to moisten

the 2 x 2.

•

Danger - Laser In Use Signage: Each operatory where the

Precise® LTM is used should have a “Laser In Use” sign placed

at the operatory entrance when a procedure is in progress.

This signage will help to reduce occurences of eye damage

caused by inadvertent exposure to laser energy. See Figure

40 on page 13.

•

Sharps Disposal and Sponge Removal: Remove cleaved ber

remnants and place them into a sharps container for disposal.

All sponges used for cleanup of lasers and bers should be

disposed of in a bag for contaminated soft products.

•

Plume Evacuation: Use high volume evacuation

suction during procedures to remove laser smoke or

‘plume’ debris. Use masks suitable for viral ltration.

Caution - laser plume may contain viable tissue particulates.

•

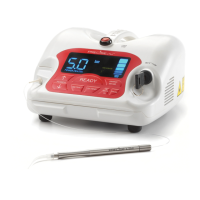

Key Switch: When the key switch is in the ON position (turn

clockwise to the right so it is 90 degrees in the vertical position),

the laser has been enabled and can be activated while in the

READY status. When not in use, insure that the key has been

turned off or that the laser is placed in the STANDBY status.

• Safety Education: Provide comprehensive safety procedure

training for all ofce personnel and include the staff in all outside

laser courses when possible. Be certain that all members of the

dental team understand how the laser works and can advise

patients as to their safety and advantages over conventional

procedures.

•

Laser Security: To prevent the unauthorized use of the laser

while not in use, the key should be removed from the unit and

maintained by the LSO.

•

Laser Stop Options: Any of these mechanisms can be used to

shut down the emission of laser energy in a real or perceived

emergency.

1. Foot Pedal – remove your foot to stop lasing

2. Engage the laser stop button

3. Key – turn off the key

4. Switch the Power to the off position (O)

5. Power Cord – unplug from the wall outlet

•

Hard Tissue Procedures: The Precise® LTM diode is not an

appropriate laser for hard tissue procedures. The diode laser

is attracted to melanin, hemoglobin and to some extent, to

water and oxygenated hemoglobin. Avoid prolonged exposure

of the energy when working in and around the cervical areas

of the tooth. Due to the thin layer of enamel in this area, the

laser’s energy may be absorbed by the hemoglobin in the

pulp and pulpal hyperemia may occur. Extended exposure to

laser energy could lead to pain and possible pulpal necrosis.

3.0.2 Laser Safety Program and Continuing Education

We recommend implementation of a Laser Safety Program

appropriate for your dental ofce. The plan may include the

following:

•

Delegation of authority and responsibility for supervision and

control of the laser to a designated LSO.

• Minimum Training requirements for users of the laser.

• Laser security against unauthorized use of the laser.

•

Standard operating procedures to regulate the work environment

in order to protect the patient and ofce staff from laser hazards.

The safe use of a laser is the responsibility of the (LSO) who can

be a full or part-time employee or the laser operator. It is their

responsibility to train the staff, maintain records concerning training

and the laser’s performance, perform safety checks, and prepares

the laser for use on a daily basis. The LSO must keep records of any

incidents that relate to the failure of the laser or any adverse effects

related to laser therapy and report such incidents as prescribed

by law. The laser safety ofcer assures that a medical follow-up

has been sought or has occurred following any adverse incident

during treatment. The LSO is responsible for the training of all ofce

personnel who are involved with the laser preparation and use.

Daily checks of the facility and equipment are also the LSO’s

responsibility. The LSO should test re the laser each day prior to

beginning each treatment procedure. For more information on

the contents of a Laser Safety Plan, you can review ANSI Standard

Z136.3 for Safe Use of Lasers in Health Care Facilities or TR IEC

60825-8 Guidelines for the Safe Use of Medical Laser Equipment.

The LSO should insure that the operator and staff attend laser

courses taught by qualied laser educators. Ongoing reviews of

laser safety procedures should be a part of normal ofce routine.

3.0.3 Food and Drug Administration

Manufacturers of products subject to performance standards

under the Federal Food, Drug, and Cosmetic Act, Chapter

V, Subchapter C - Electronic Product Radiation Control are

required to certify compliance with the regulations and furnish

various reports to the Center for Devices and Radiological

Health (CDRH). For medical laser manufacturers, additional

review by the FDA of the safety and effectiveness of the device

is required. Companies who intend to market a medical laser

today must receive authorization from the FDA to permit the

device into commercial distribution. There are two forms of

premarket clearance procedures. The premarket notication

510(k) procedure is principally used for those devices that are

documented to be substantially equivalent to legally marketed

Class I and Class II devices. For new devices not equivalent to

legally marketed devices, a more complex

PMA is required.

Loading...

Loading...