12

Carlyle ships most new and service compressors without oil.

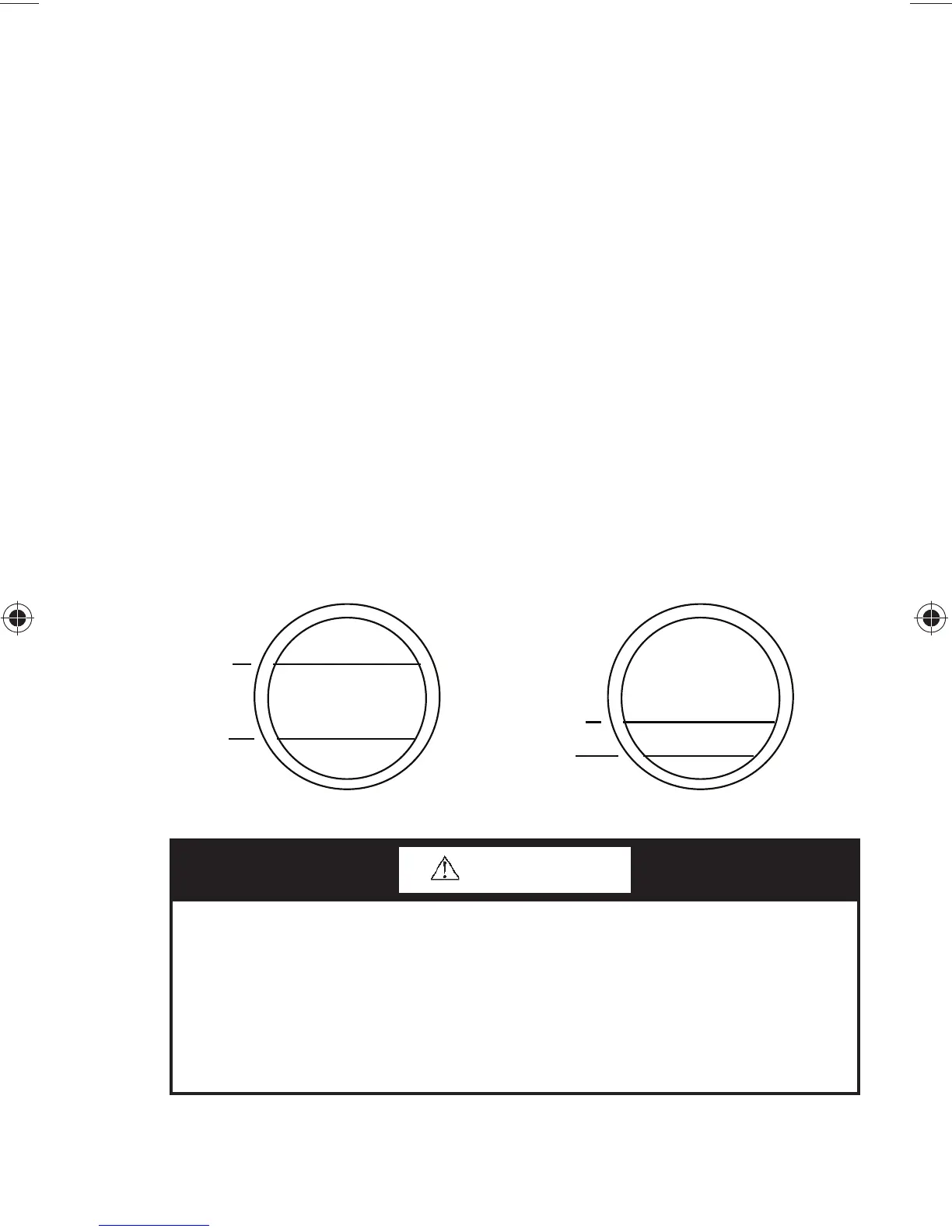

The oil level for 06CC size 16 to 37 Cfm compressors and

all 06D compressors should be at 1/4 to 3/4 of the sight

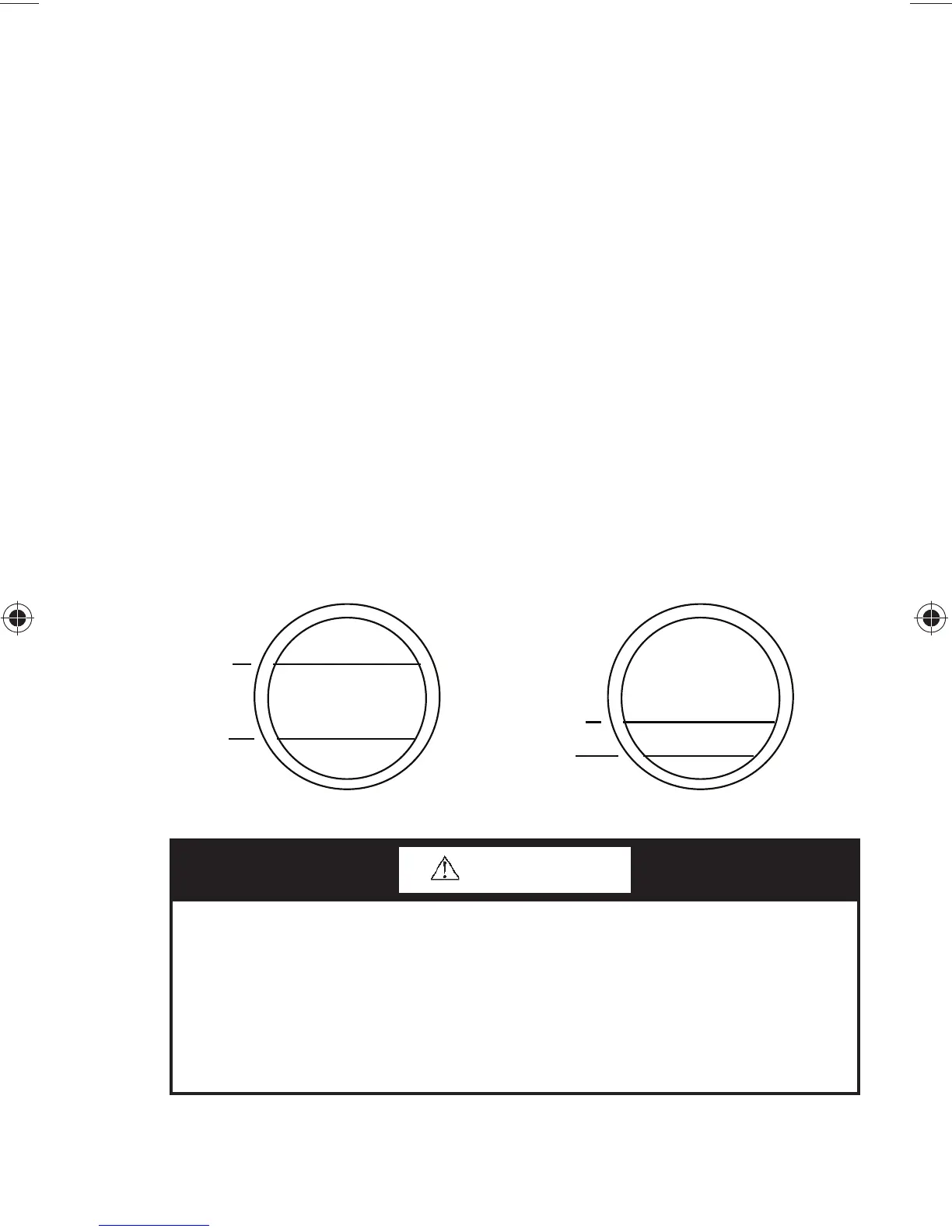

glass. The oil level for 06CC size 50 to 99 Cfm compressors

and all 06E compressors should be at 1/8 to 3/8 of the sight

glass. See Section 3.6, pages 69 to 71 for the proper Car-

lyle approved oils for the selected refrigerant. Oil should

be added through the recommended oil fill connection

ports on the compressor as identified in the figures in

Section 2.5.

Once the compressor system has been running for at least 24

hours, the most accurate oil levels are observed when the

compressor is off. Oil levels in the sight glass can be

affected by the rotation of the running gear.

CAUTION

Do not add excess oil. It is especially important on the 06E

and 06CC (50 to 99 Cfm) compressors that excess oil not

be added to the system. Laboratory tests and field experi-

ence indicate excessive oil levels can cause blown valve

plate and cylinder head gaskets, increase compressor oper-

ating temperatures, and cause oil equalization problems.

06CC (16 TO 37 CFM) AND 06D

3/4 (MAX)

1/4 (MIN)

06CC (50 TO 99 CFM) AND 06E

3/8 (MAX)

1/8 (MIN)

Loading...

Loading...