22

Troubleshooting Guide - 06D, 06E and 06CC Compressors

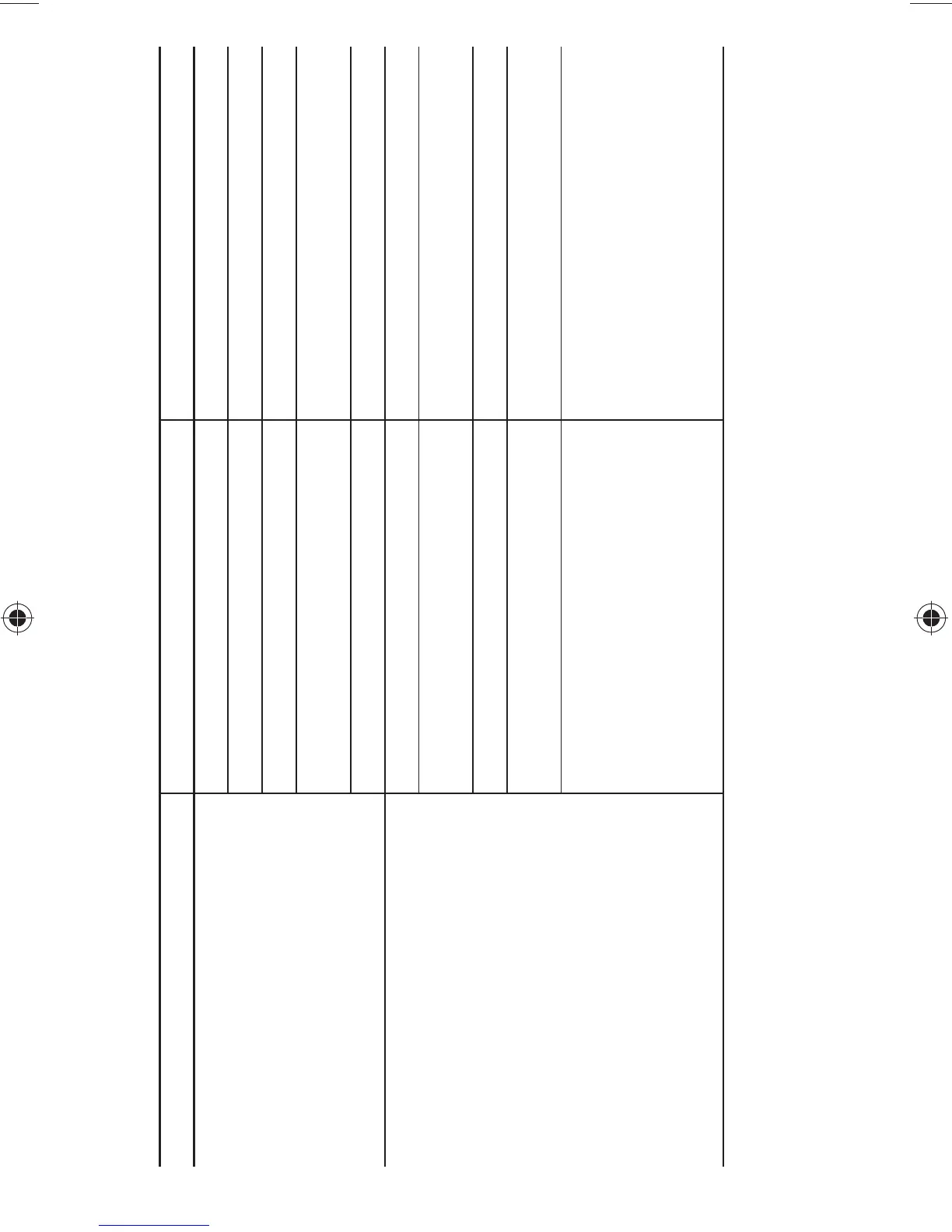

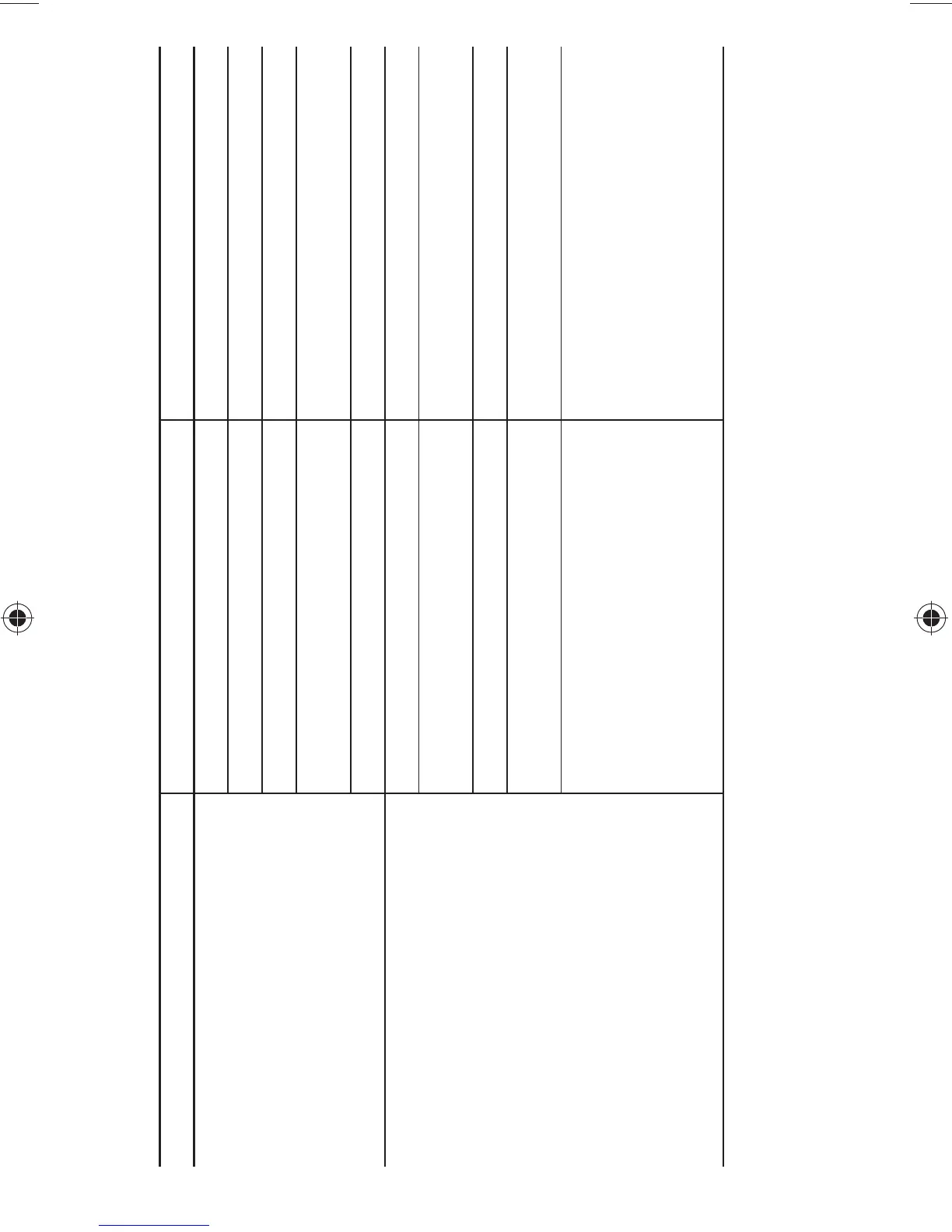

OBSERVATION POSSIBLE CAUSE REMEDY

1. Compressor will not start Power off Check main switch, fuses and wiring

Overcurrent protection open Reset manually

Oil safety switch open Reset manually

Loose electrical connections or faulty wiring Tighten connections. Check wiring and

rewire if necessary.

Compressor motor burned out Inspect and replace compressor if defective.

2. Low compressor capacity or inability to

pull down system

Broken connecting rods or pistons Replace compressor

For 06CC only:

Blown valve plate or cylinder head gasket

See No. 3

Leaky valve plates or worn valve seats Replace valve plate assembly

Leaky or broken suction valves Pump down, remove cylinder head, examine

valves and valve seats. Replace if necessary.

Check pressure difference between

suction, interstage and discharge if:

a. pressure is low between suction and

interstage

a. Check for problems in low stage heads

b. pressure is low between interstage and

discharge

b. Check for problems in high stage head

Loading...

Loading...