76

Step 4 — Make Electrical Connections

The electrical service to the unit should be compared to the unit

nameplate to verify compatibility. The routing and sizing of all

piping, and the type and sizing of all wiring and other electrical

components such as circuit breakers, disconnect switches, etc.

should be determined by the individual job requirements. Verify

the electrical conductor size is suitable for the distance to the

equipment connection and will support the equipment electrical

load. All installations should be made in compliance with all gov

-

erning codes and ordinances. Compliance with all codes is the

responsibility of the installing contractor.

The unit serial plate lists the unit electrical characteristics such as

the required supply voltage, fan and heater amperage and required

circuit ampacities. The unit wiring diagram shows all unit and

field wiring. Since each project is different and each unit on a proj

-

ect may be different, the installer must be familiar with the wiring

diagram and serial plate on the unit BEFORE beginning any

wiring.

All components furnished for field installation by either the facto-

ry or the controls contractor should be located and checked for

proper function and compatibility. All internal components should

be checked for shipping damage, and any loose connections

should be tightened to minimize problems during start-up.

Any devices such as fan switches or thermostats that have been

furnished from the factory for field installation must be wired in

strict accordance with the wiring diagram that appears on the unit.

Failure to do so could result in personal injury or damage to com

-

ponents and will void all manufacturer’s warranties.

The fan motor(s) should never be controlled by any wiring or

device other than the 3-speed switch or thermostat/ switch combi

-

nation without factory authorization. Fan motor(s) may be tempo-

rarily wired for use during construction only with prior factory

approval in strict accordance with the instructions issued at that

time.

Units with optional factory-furnished and installed aquastats may

be shipped with the aquastats mounted on a coil stub-out. Remove

the aquastat before installation of a valve package. Consult the

factory piping diagram in the approved submittals for proper loca

-

tion when reinstalling the aquastats. If the valve package is field-

furnished, the aquastat must be installed in a location where it will

sense the water temperature regardless of control valve position. A

bleed bypass may be required to guarantee proper aquastat

operation.

All field wiring should be done in accordance with governing

codes and ordinances. Any modification of the unit wiring without

factory authorization will void all of the factory warranties, and

will nullify any agency listings.

The manufacturer assumes no responsibility for any damages and/

or injuries resulting from improper field installation and/or wiring.

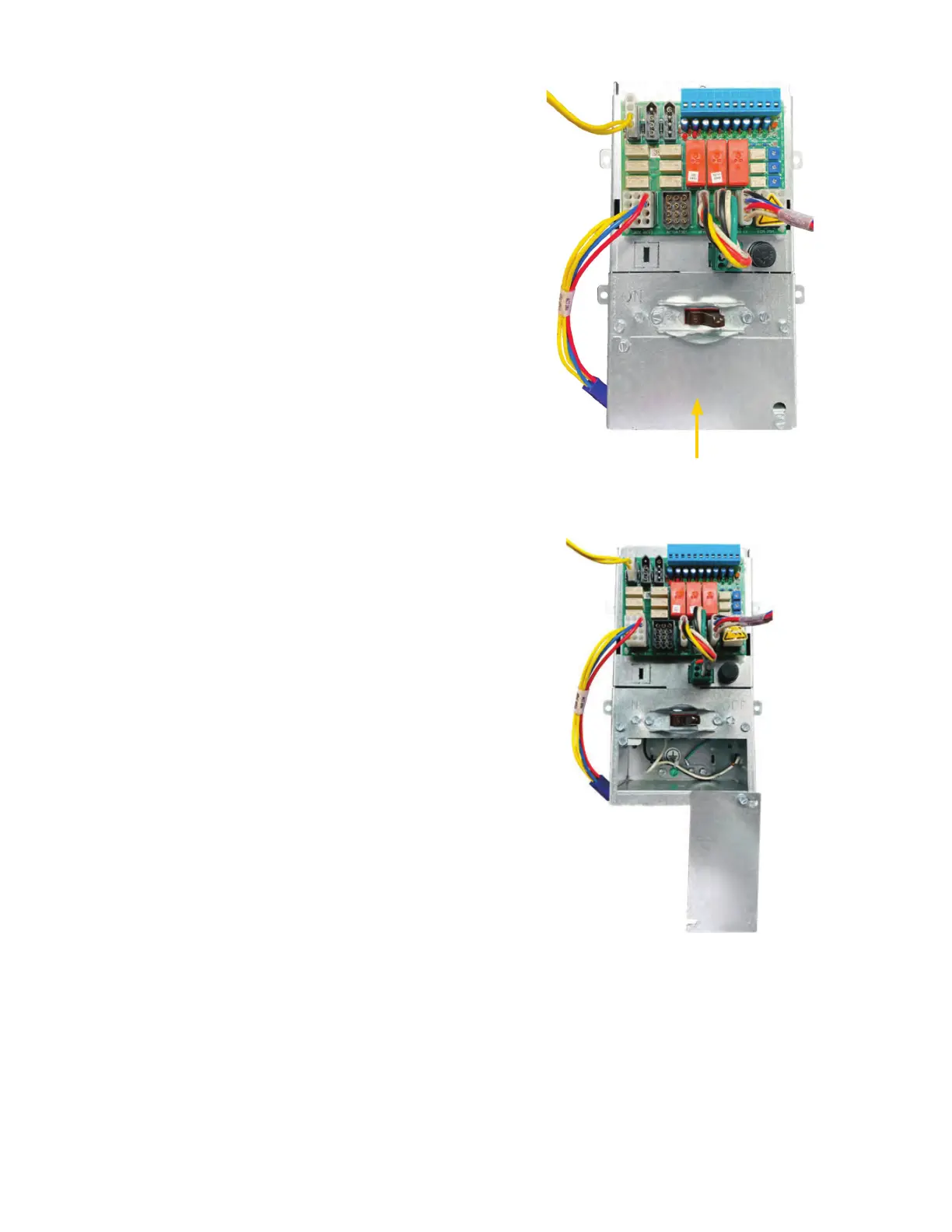

1. After planning for and bringing incoming power to the unit,

locate the control box and cover plate (incoming electrical

power wiring compartment). Refer to Fig. 81.

2. Determine appropriate knock out to feed incoming power

wiring into box.

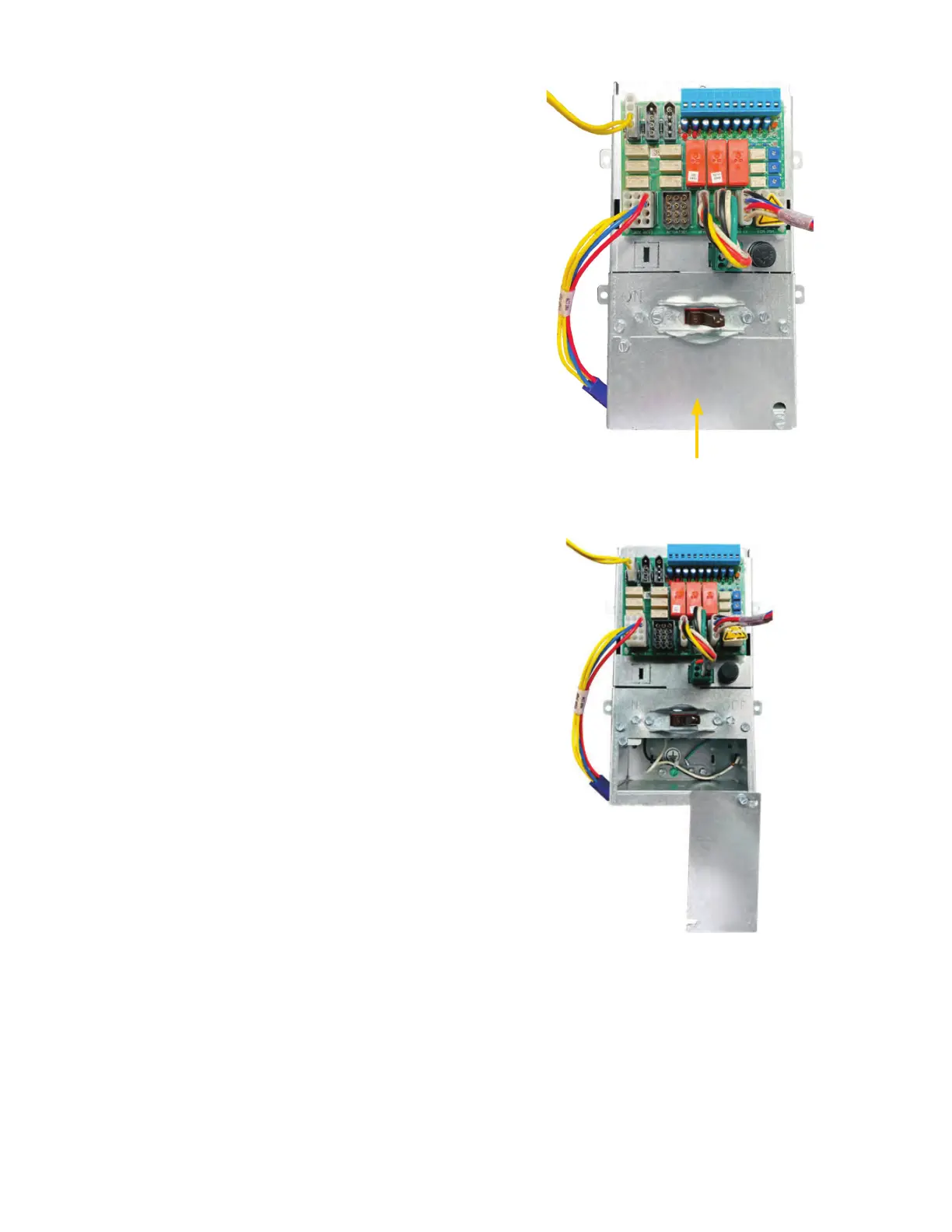

3. Loosen screws to rotate cover plate to access wiring. Refer to

Fig. 82.

4. Secure incoming power wiring with proper service entrance

connector and/or appropriate strain relief. Use wire nuts

connections that meet wire gauge requirements. See

Fig. 83-85.

5. Replace cover plate and secure screws.

Fig. 81 — Control Box with Cover Plate

Fig. 82 — Loosened Covered Plate

Incoming Electrical Power

Wiring Compartment

Loading...

Loading...