7

GB-21

8.4 Note On Adding Refrigerant

Note: 1) Please use tools for R410A/R32 system respectively;

2) The standard pipe length is 7.5m (24.6’). When the pipe length is over 7.5m, the additional

refrigerant should be added according to the piping length.

8.5 Safety And Leakage Check

CAUTION

• Refrigerant charging must be performed after wiring, vacuuming, and the leak testing.

•

DO NOT exceed the maximum allowable quantity of refrigerant or overcharge the system.

Doing so can damage the unit or impact it’s functioning.

•

Charging with unsuitable substances may cause explosions or accidents. Ensure that the

appropriate refrigerant is used.

Refrigerant containers must be opened slowly. Always use protective gear when charging the system.

•

•

DO NOT mix refrigerants types.

N=2(one-twin models), N=3(one-three models), N=4(one-four models), N=5(one-five models).Depending on the length

of connective piping or the pressure of the evacuated system, you made need to add refrigerant. Refer to table

below for refrigerant amounts to be added:

ADDITIONAL REFRIGERANT PER PIPE LENGTH

Connective Pipe

Length

Air Purging

Method

Additional Refrigerant

(

R410A/R32)

Pre-charge pipe length(ft/m)

(Standard pipe lengthxN)

Vacuum Pump

N/A

More than

(Standard pipe lengthxN)ft/m

Vacuum Pump

Liquid Side: Ø 6.35 (Ø 1/4”)

(Total pipe length - standard pipe lengthxN) x15g/m /

(Total pipe length - standard pipe lengthxN) x12g/m

Liquid Side: Ø 9.52 (Ø 3/8”)

(Total pipe length - standard pipe lengthxN) x30g/m /

(Total pipe length - standard pipe lengthxN) x24g/m

Electrical safety check

Perform the electrical safety check after

completing installation. Cover the following areas:

1. Insulated resistance

The insulated resistance must be more than 2MΩ.

2. Grounding work

After finishing grounding work, measure the grounding

resistance by visual detection and using the grounding

resistance tester.

Make sure the grounding resistance is less than 4Ω.

3. Electrical leakage check (performing during test while

unit is on)

During a test operation after completed installation,

use the electroprobe and multimeter to perform an

electrical leakage check. Turn off the unit immediately

if leakage happens. Try and evaluate different solutions

until the unit operates properly.

Gas leak check

1. Soap water method:

Apply a soap-water solution or a liquid neutral detergent

on the indoor unit connection or outdoor unit connections

with a soft brush to check for leakage of the connecting

points of the piping. If bubbles emerge, the pipes are

experiencing leakage.

2. Leak detector

Use the leak detector to check for leakage.

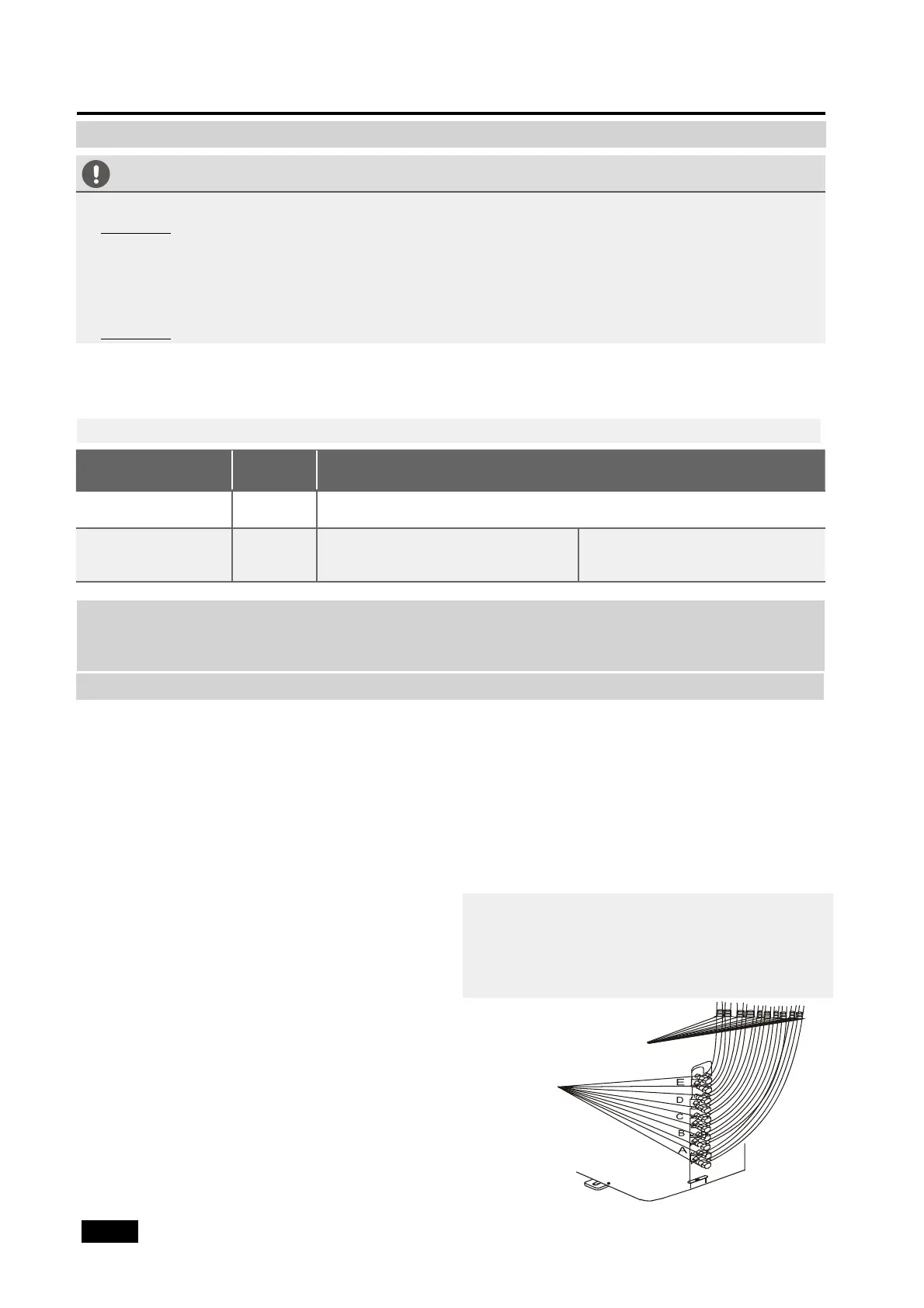

NOTE: The illustration is for example purposes

only. The actual order of A, B, C, D, and E on the

machine may be slightly different from the unit

you purchased but the general shape will remain

the same.

Indoor unit

check point

Outdoor unit

check point

A, B,C,D are points for the one-four type.

A, B,C,D, and E are points for the one-five type.

Fig. 8.4

8. AIR EVACUATION

Loading...

Loading...