16

4. Divide number of seconds in Step 3 into 3600 (number of

seconds in one hr).

5. Multiply result of Step 4 by the number of cu ft shown for

one revolution of test dial to obtain ft

3

of gas flow per hr.

6. Multiply result of Step 5 by Btu heating value of gas to

obtain total measured input in Btuh. Compare this value

with heating input shown in Table 3 (Consult the local gas

supplier if the heating value of gas is not known).

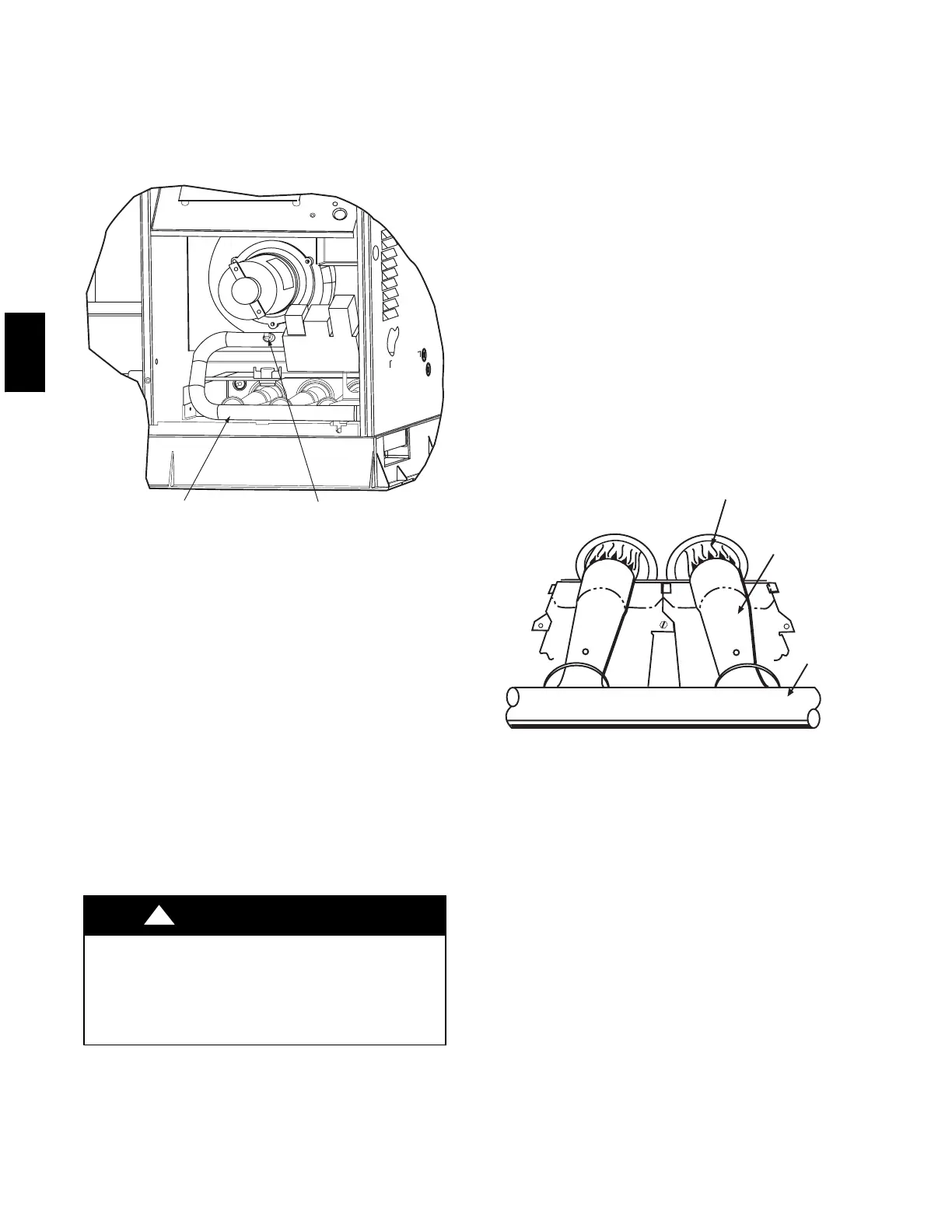

MANIFOLD PIPE PLUG

C99019

Fig. 16 -- Burner Assembly

EXAMPLE: Assume that the size of test dial is 1 ft

3

, one

revolution takes 32 sec., and the heating value of the gas is 1050

Btu/ft3. Proceed as follows:

1. 1. 32 sec. to complete one revolution.

2. 3600 ÷ 32 = 112.5.

3.112.5x1=112.5ft

3

of gas flow/hr.

4. 112.5 x 1050 = 118,125 Btuh input.

If the desired gas input is 115,000 Btuh, only a minor change in

the manifold pressure is required.

Observe manifold pressure and proceed as follows to adjust gas

input:

1. Remove cover screw over regulator adjustment screw on

gas valve.

2. Turn regulator adjustment screw clockwise to increase gas

input, or turn regulator adjustment screw counterclockwise

to decrease input. Manifold pressure must be between 3.4

and 3.6 in. wc. Unsafe operation of the unit may result if

manifold pressure is outside this range. Personal injury or

unit damage may result.

FIRE AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury

or death and/or property damage.

Unsafe operation of the unit may result if manifold pressure

is outside this range.

!

WARNING

3. Replace cover screw cap on gas valve.

4. Turn off gas supply to unit. Remove manometer from

pressure tap and replace pipe plug on gas valve. Turn on

gas to unit and check for leaks.

Measure Manifold Pressure (Propane Units)

The main burner orifices on a propane gas unit are sized for the

unit rated input when the manifold pressure reading matches the

level specified in Table 3.

Proceed as follows to adjust gas input on a propane gas unit:

1. Turn off gas to unit.

2. Remove pipe plug on manifold and connect manometer

(See Fig. 16).

3. Turn on gas to unit.

4. Remove cover screw over regulator adjustment screw on

gas valve.

5. Adjust regulator adjustment screw to the correct manifold

pressure, as specified in Table 3. Turn adjusting screw

clockwise to increase manifold pressure, or turn adjusting

screw counterclockwise to decrease manifold pressure.

6. Replace cover screw.

7. Turn off gas to unit. Remove manometer from pressure

tap. Replace pipe plug on gas valve, then turn on gas to

unit. Check for leaks.

CHECK BURNER FLAME

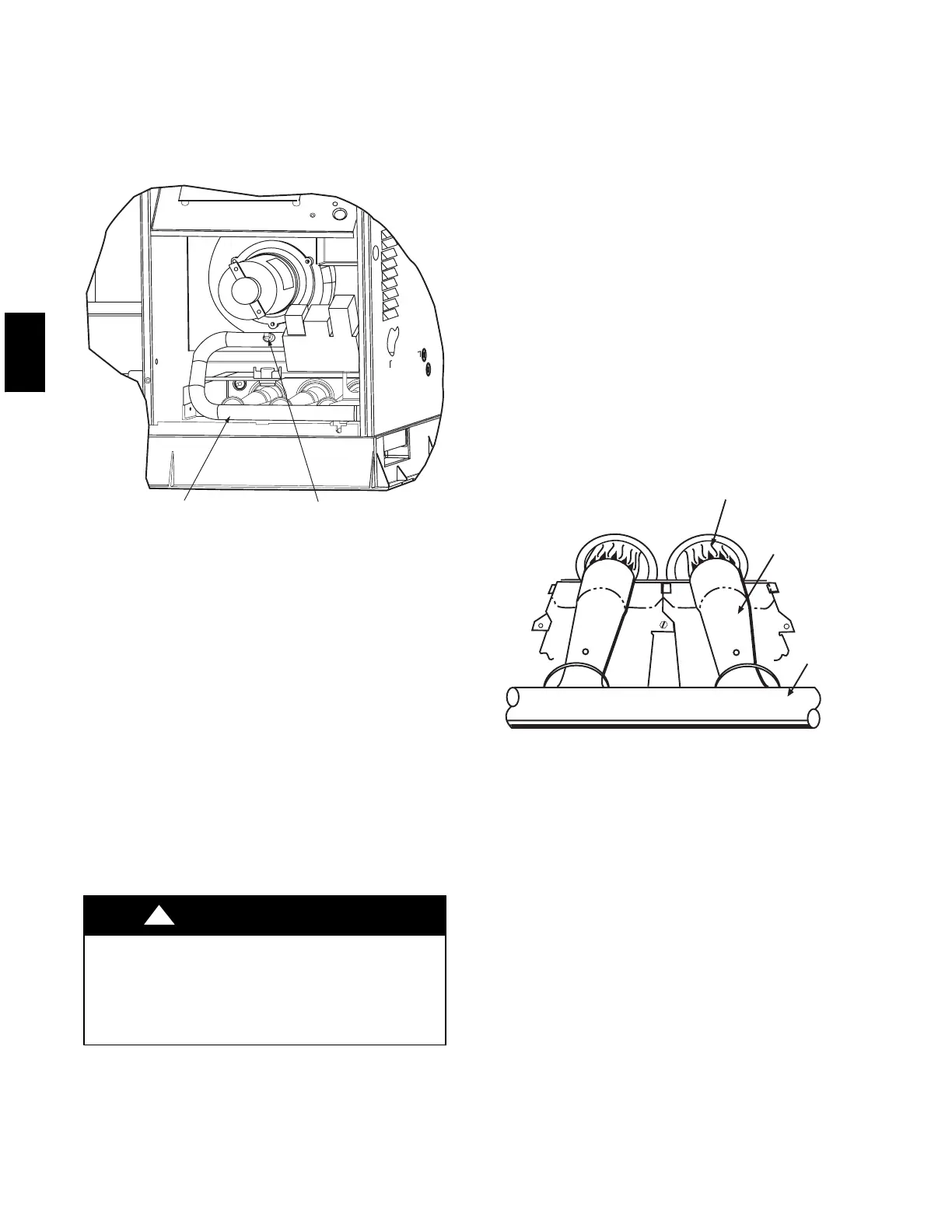

With burner access panel removed, observe the unit heating

operation. Watch the burner flames to see if they are light blue

and soft in appearance, and that the flames are approximately the

same for each burner. Propane will have blue flame with yellow

tips (See Fig. 17). Refer to the Maintenance section for

information on burner removal.

MANIFOLD

BURNER

BURNER FLAME

C99021

Fig. 17 -- Monoport Burner

AIRFLOW AND TEMPERATURE RISE

The heating section for each size unit is designed and approved

for heating operation within the temperature--rise range stamped

on the unit rating plate. Table 4 shows the approved temperature

rise range for each heating input, and the air delivery cfm at

various temperature rises. The heating operation airflow must

produce a temperature rise that falls within the approved range.

Refer to Indoor Airflow and Airflow Adjustments section to

adjust heating airflow when required.

LIMIT SWITCHES

Normally closed limit switch (LS) completes the control circuit

through the thermostat R circuit. Should the leaving--air

temperature rise above the maximum allowable temperature, the

limit switch opens and the R control circuit “breaks.” Any

interruption in the R control circuit instantly closes the gas valve

and stops gas flow to the burners and pilot. The blower motor

continues to run until LS resets.

When the air temperature at the limit switch drops to the

low--temperature setting of the limit switch, the switch closes and

completes the R control circuit. The electric--spark ignition

system cycles and the unit returns to normal heating operation.

48XP

Loading...

Loading...