9

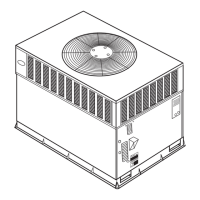

Ta ble 2 – Maximum Gas Flow Capacity*

NOMINAL

IRON PIPE,

SIZE (IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE, FT†

10 20 30 40 50 60 70 80 90 100 125 150 175 200

1/2 .622 175 120 97 82 73 66 61 57 53 50 44 40 — —

3/4 .824 360 250 200 170 151 138 125 118 110 103 93 84 77 72

1 1.049 680 465 375 320 285 260 240 220 205 195 175 160 145 135

11/4 1.380 1400 950 770 600 580 530 490 460 430 400 360 325 300 280

11/2 1.610 2100 1460 1180 990 900 810 750 690 650 620 550 500 460 430

* Capacity of pipe in cu ft of gas per hr for gas pressure of 0.5 psig or Protection Association NFPA 54. less. Pressure drop of 0.5--in. wc (based on a 0.60 specific

gravity gas). Refer to Table, National Fire

† This length includes an ordinary number of fittings.

5. Install an accessible, external, manual main shutoff valve

in gas supply pipe within 6 ft of heating section.

6. Install ground--joint union close to heating section

between unit manual shutoff and external manual main

shut--off valve.

7. Pressure--test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

NOTE: Pressure test the gas supply system after the gas supply

piping is connected to the gas valve. The supply piping must be

disconnected from the gas valve during the testing of the piping

systems when test pressure is in excess of 0.5 psig. Pressure test

the gas supply piping system at pressures equal to or less than 0.5

psig. The unit heating section must be isolated from the gas

piping system by closing the external main manual shutoff valve

and slightly opening the ground--joint union.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death and/or property damage.

--Connect gas pipe to unit using a backup wrench to avoid

damaging gas controls.

--Never purge a gas line into a combustion chamber. Never test

for gas leaks with an open flame. Use a commercially available

soap solution made specifically for the detection of leaks to

check all connections.

--Use proper length of pipe to avoid stress on gas control

manifold.

--If a flexible connector is required or allowed by authority

having jurisdiction, black iron pipe shall be installed at furnace

gasvalve andextend aminimum of2 in.outside furnace casing.

--If codes allow a flexible connector, always use a new

connector. do not use a connector which has previously

serviced another gas appliance.

!

WARNING

8. Check for gas leaks at the field--installed and

factoryinstalled gas lines after all piping connections have

been completed. Use soap--and--water solution (or method

specified by local codes and/or regulations).

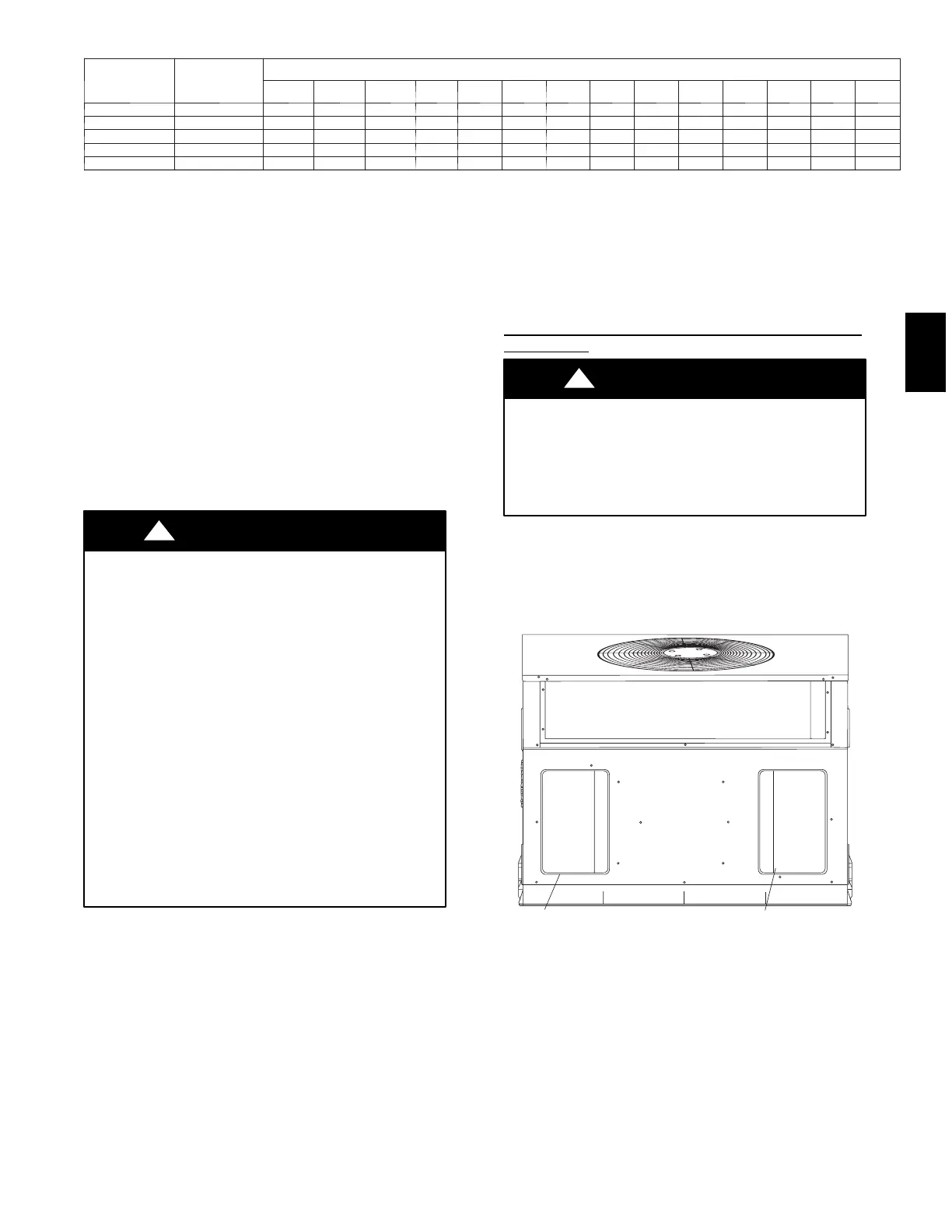

Step 9 — INSTALL DUCT CONNECTIONS

The unit has duct flanges on the supply-- and return--air openings

on the side and bottom of the unit. For downshot applications, the

ductwork connects to the roof curb (See Fig. 2 and 3 for

connection sizes and locations).

CONFIGURING UNITS FOR DOWNFLOW (VERTICAL)

DISCHARGE

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch.

!

WARNING

1. Open all electrical disconnects before starting any service

work.

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit base.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base (See Fig. 9 & 10).

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

C99011

Fig. 9 -- Supply and Return Duct Opening

48XP

Loading...

Loading...