4

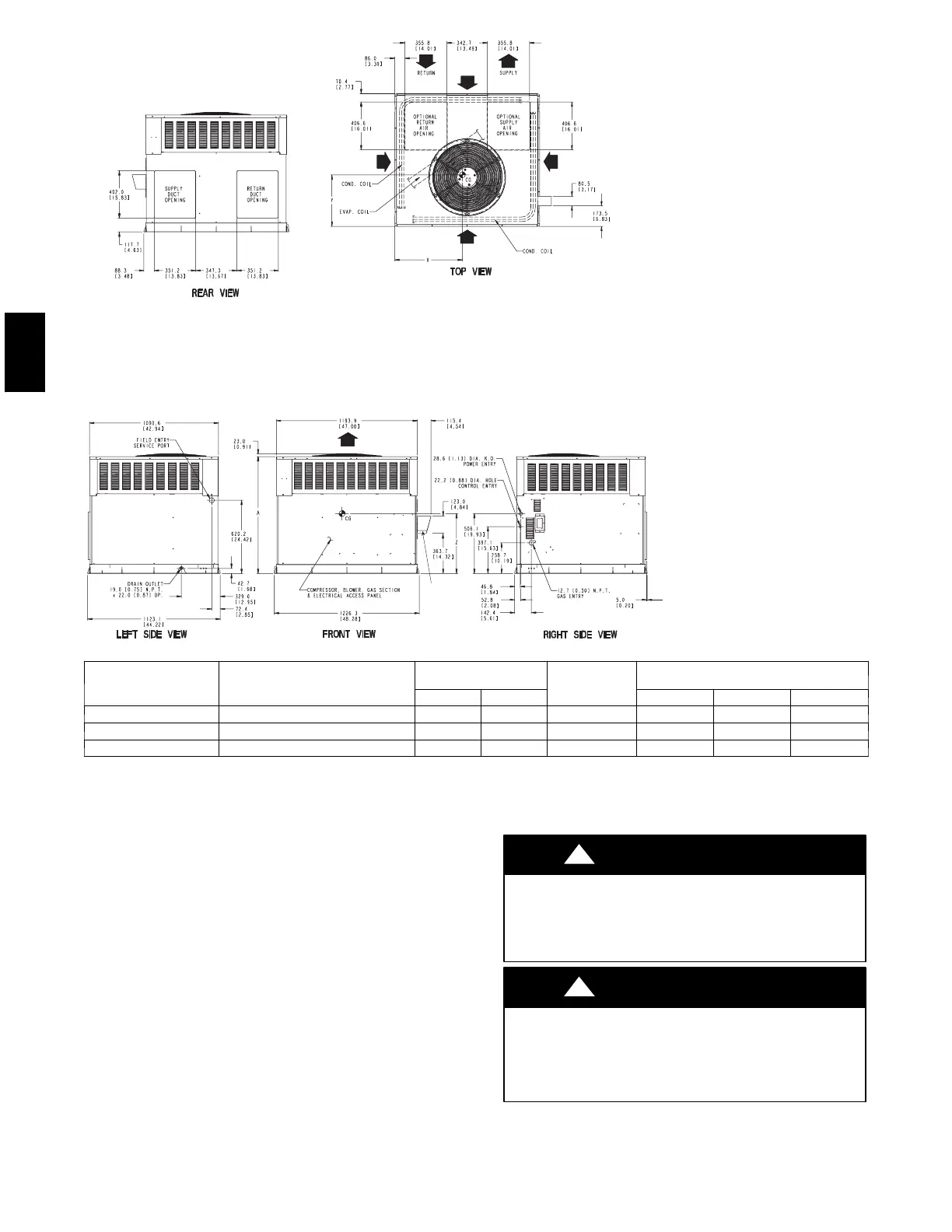

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

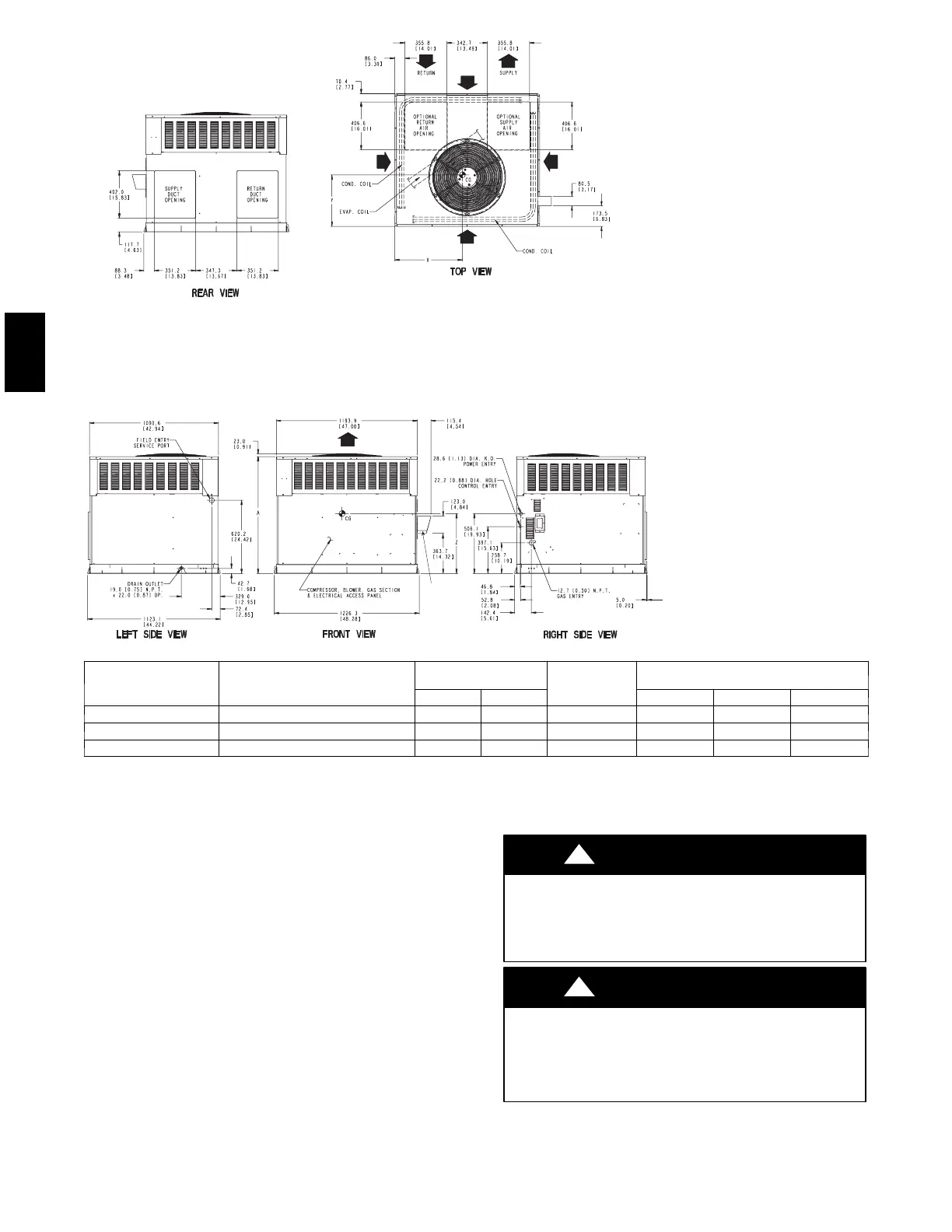

in. [mm]

EVAP. COIL ACCESS SIDE..............................................................36.00 [914.0]

POWER ENTRY SIDE......................................................................36.00 [914.0]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP.........................................................................................36.00 [914.0]

SIDE OPPOSITE DUCTS ................................................................36.00 [914.0]

DUCT PANEL ...................................................................................12.00 [304.8] *

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 12.00 [304.8] FROM

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

REQUIRED CLEARANCE TO COMBUSTIBLE MATL.

in. [mm]

TOP OF UNIT...................................................................................14.00 [355.6]

DUCT SIDE OF UNIT.........................................................................2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................14.00 [355.6]

BOTTOM OF UNIT .............................................................................0.50 [12.7]

ELECTRIC HEAT PANEL .................................................................36.00 [914.4]

NEC. REQUIRED CLEARANCES.

MILLIMETERS [IN.]

BETWEEN UNITS, POWER ENTRY SIDE ....................................42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE ...36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE.........................42.00 [1066.8]

FLUE HOOD

C99074

UNIT

ELECTRICAL

CHARACTERISTICS

UNIT WEIGHT

UNIT HEIGHT

IN. [MM]

“A”

CENTER OF GRAVITY

IN. [MM]

lb kg X Y Z

48XP042--060/090 208/230--1--60, 208/230--3--60 440 200 42.98 [1091.7] 21.0 [533.4] 20.5 [520.7] 16.6 [421.6]

48XP048--090/115/130 208/230--1--60, 208/230--3--60 463 210 44.98 [1142.5] 19.5 [495.3] 21.3 [539.8] 18.0 [457.2]

48XP060--090/115/130 208/230--1--60, 208/230--3--60 499 226 46.98 [1193.3] 21.0 [533.4] 20.0 [508.0] 17.6 [447.0]

Fig. 3 -- 48XP042--060 Unit Dimensions

Step 5 — Rig and Place Unit

Rigging and handling of this equipment can be hazardous for

many reasons due to the installation location (roofs, elevated

structures, etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Use spreader bars or crate top when rigging the unit. The units

must be rigged for lifting (See Fig. 6). Refer to Table 1 for

operating weight. Use extreme caution to prevent damage when

moving the unit. Unit must remain in an upright position during

all rigging and moving operations. The unit must be level for

proper condensate drainage; therefore, the ground--level pad or

accessory roof curb must be level before setting the unit in place.

When a field--fabricated support is used, be sure that the support

is level and properly supports the unit. Lifting point should be

directly over the center of gravity for the unit.

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Never stand beneath rigged units or lift over people.

!

WARNING

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal

injury or death.

Never exceed 200 lbs. per bracket lifting force.

!

WARNING

48XP

Loading...

Loading...