8

TROUBLESHOOTING THE ECM MOTOR

EcoBlue™ motors are designed with several built-in protections

included in the motor software. If the motor detects a fault it will

safely shut down. See Table 4, “Supply Fan Motor Logic and

Safety Relays” on page 36 for a complete list.

Troubleshooting the motor requires a voltmeter.

1. Disconnect main power to the unit.

2. Disconnect motor plug in supply section of the unit.

3. Restore main unit power.

4. Check for proper line voltage at motor power leads Black

(PL1-1), Yellow (PL1-2), and Blue (PL1-3). Blue is only

present on 3-phase motors. See the following table.

5. Disconnect main power.

6. Reconnect motor plug in supply section of unit.

7. Restore main power.

8. Check for proper motor control voltage signal of 9.7 vdc to

10.3 vdc at IFM-1 and IFM-3 on Unit Control Board

(UCB). See Fig. 10.

9. Using a jumper wire from unit control terminals R to G,

engage motor operation.

10. Verify control signal from user speed selection switch by

placing voltmeter taps in provided terminals marked vdc.

Signal should be between 3.8 vdc and 10.3 vdc.

11. If the motor does not start and run, remove the fan assembly

and replace the motor with one having the same part num-

ber. Do not substitute with an alternate design motor as the

voltage/speed programming will not be the same as that on

an original factory motor.

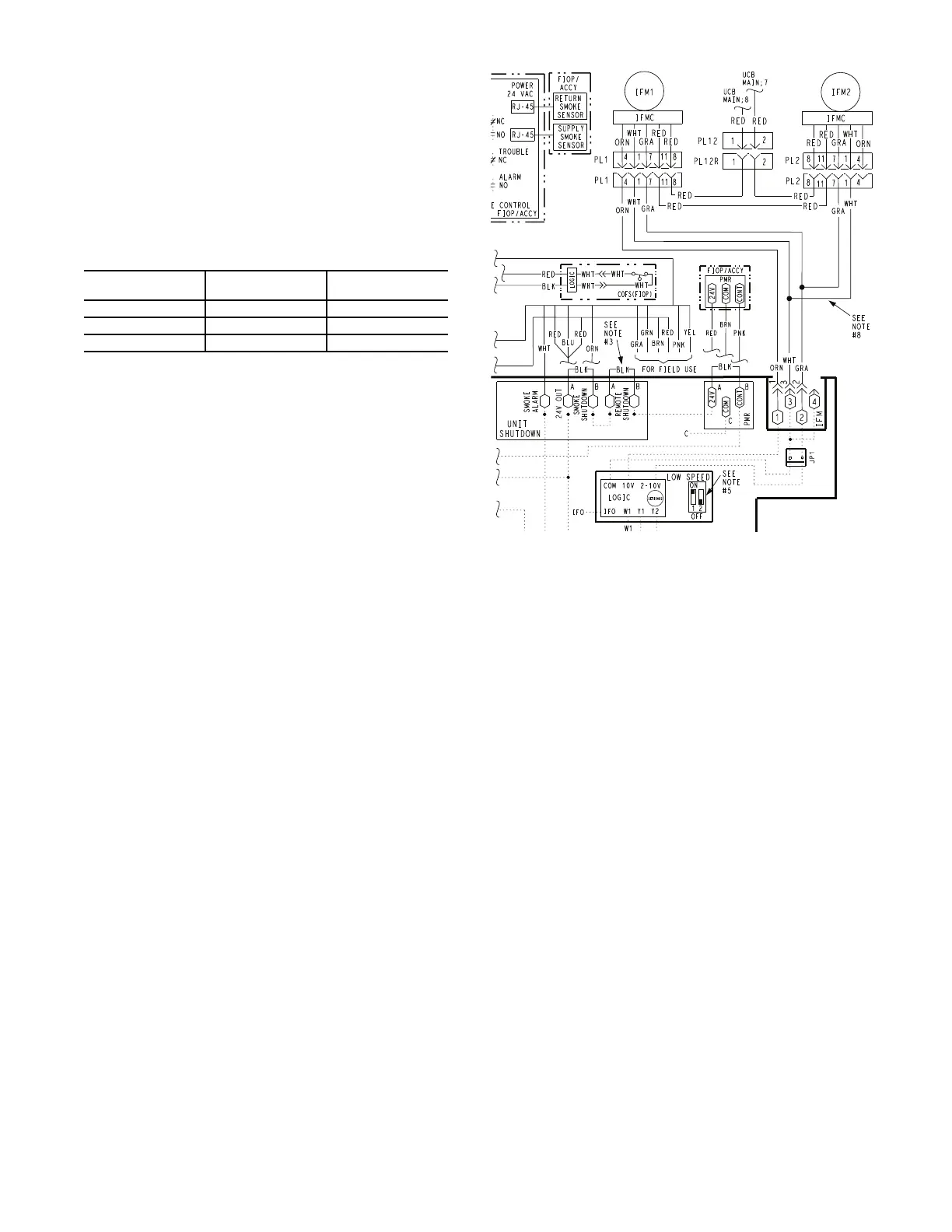

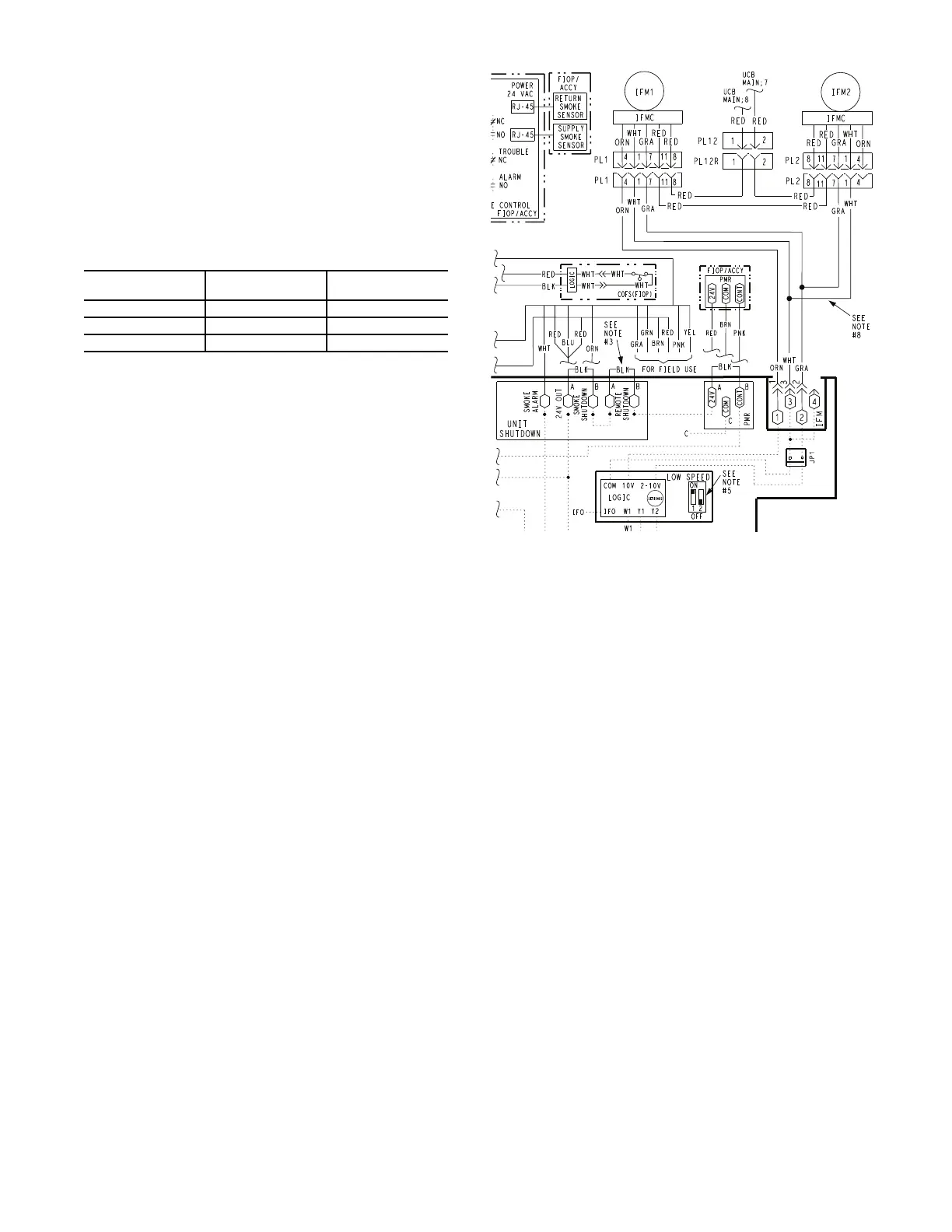

Fig. 10 — Supply Fan Control Wiring Diagram

50FC UNIT

VOLTAGE

MOTOR VOLTAGE MIN-MAX VOLTS

208/230 230 187-253

460 460 360-506

575 575 517-633

Loading...

Loading...