PG80VTLA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

25

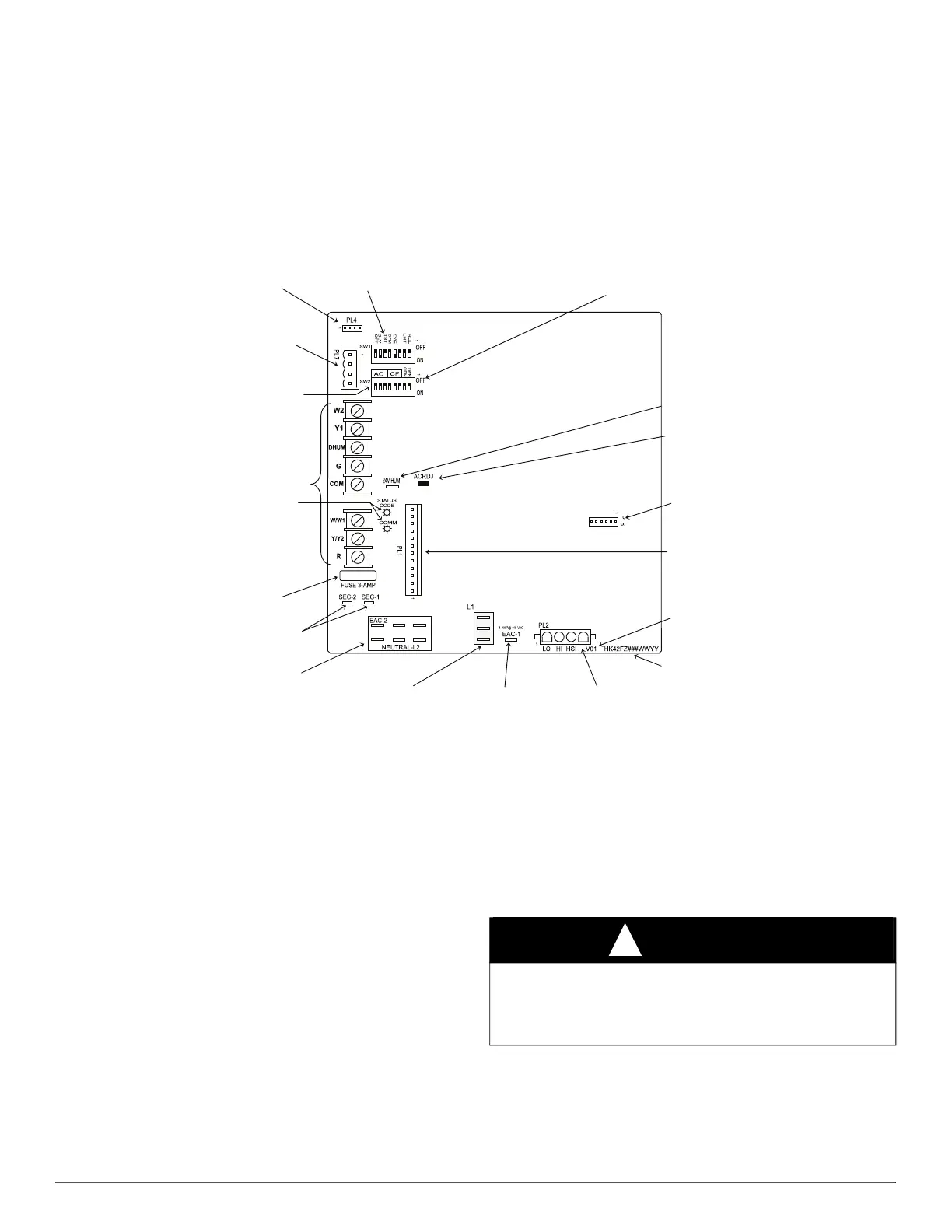

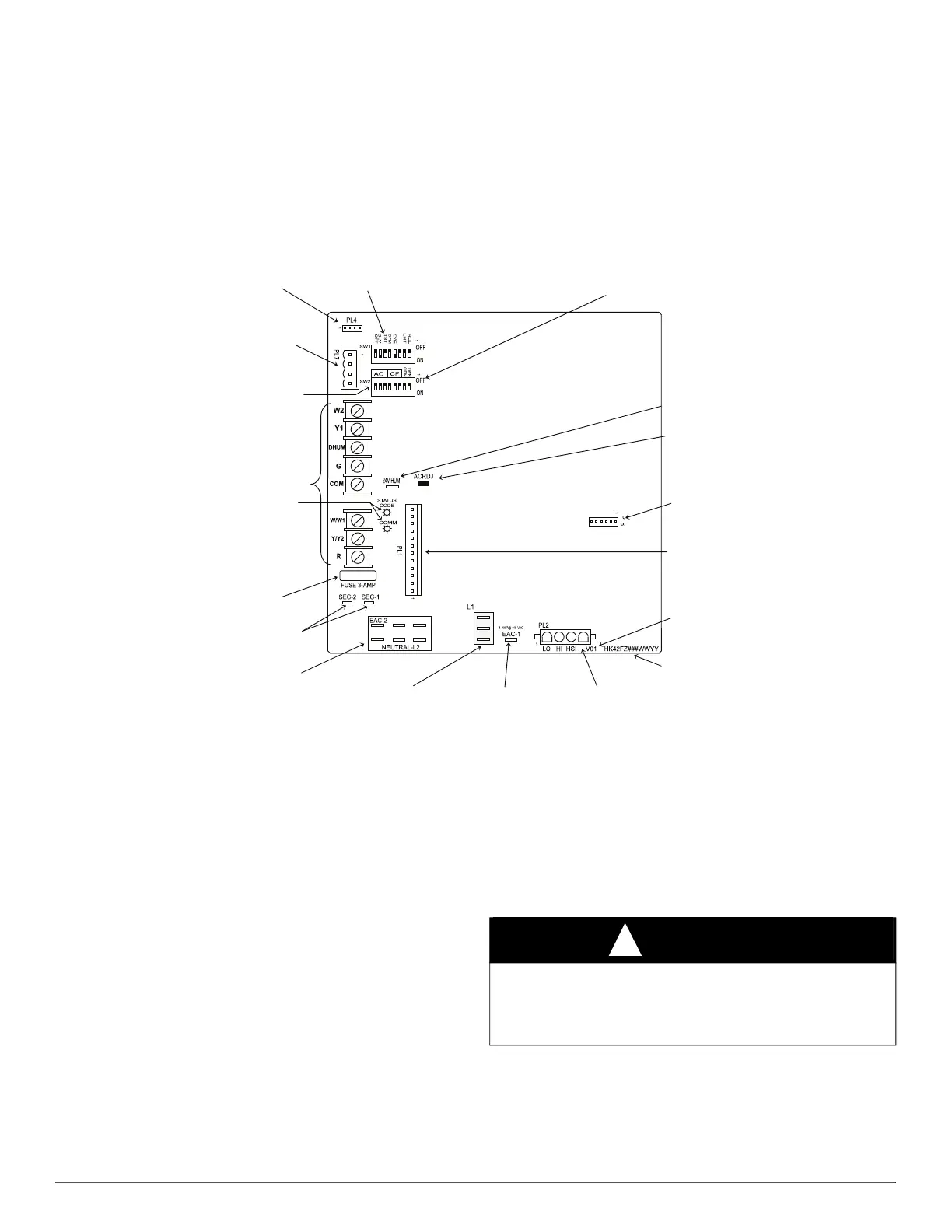

ACCESSORIES

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used) using 1/4-in

female quick connect terminals to the two male 1/4-in

quick-connect terminals on the control board marked EAC-1 and

EAC-2. The terminals are rated for 115VAC, 1.0 amps maximum

and are energized during blower motor operation. (See Fig. 36).

2. Humidifier (HUM)

Connect an accessory 24 VAC, 0.5 amp. maximum humidifier

(if used) to the 1/4-in male quick-connect HUM terminal and

COM-24V screw terminal on the control board thermostat strip.

The HUM terminal is energized when blower is energized in

heating. (See Fig. 36).

NOTE: DO NOT connect furnace control HUM terminal to HUM

(humidifier) terminal on Thermidistat, Zone Controller or similar device.

See Thermidistat

©

, Zone Controller, thermostat, or controller

manufacturer’s instructions for proper connection.

A190044

Fig. 36 – Variable Speed Furnace Control for ECM Blower Motor

VENTING

The furnace shall be connected to a listed factory built chimney or vent,

or a clay-tile lined masonry or concrete chimney. Venting into an unlined

masonry chimney or concrete chimney is prohibited.

When an existing Category I furnace is removed or replaced, the original

venting system, may no longer be sized to properly vent the attached

appliances. An improperly sized Category I venting system could cause

the formation of condensate in the furnace and vent, leakage of

condensate and combustion products, and spillage of combustion

products into the living space.

Vent system or vent connectors may need to be resized. Vent systems or

vent connectors must be sized to approach minimum size as determined

using appropriate table found in the current edition of NFGC.

GENERAL VENTING REQUIREMENTS

Follow all safety codes for proper vent sizing and installation

requirements, including local building codes, the National Fuel Gas

Code NFPA 54/ANSI Z223.1 (NFGC), Parts 12 and 13 in the United

States, the local building codes, and furnace and vent manufacturers’

instructions.

These furnaces are design-certified as Category I furnaces in accordance

with ANSI Z21.47/CSA 2.3 and operate with a non-positive vent static

pressure to minimize the potential for vent gas leakage. Category I

furnaces operate with a flue loss not less than 17% to minimize the

potential for condensation in the venting system. These furnaces are

approved for common venting and multi-story venting with other fan

assisted or draft hood equipped appliances in accordance with the

NFCG, local building codes, and furnace and vent manufacturers’

instructions.

The following information and warning must be considered in addition

to the requirements defined in the NFGC.

1. If a vent (common or dedicated) becomes blocked, the furnace will

be shut off by the draft safeguard switch located on the vent elbow.

2. Two-stage furnaces require Type B vent connectors outside the

casing in all configurations. Single wall vent connector may be

used inside the furnace casing with the transition to Type B vent

outside the furnace casing. Size the connector so that the FAN-Min

24-V THERMOSTAT

TERMINALS

PL2 – (115VAC) HOT SURFACE

IGNITER SIGNAL & INDUCER

MOTOR CONNECTOR

115-VAC (L2) NEUTRAL

CONNECTIONS

115-VAC (L1) LINE

VOLTAGE CONNECTIONS

EAC-1 TERMINAL

115-VAC 1.0 AMP MAX.

PL1 – LOW

VOLTAGE MAIN

HARNESS

CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

3-AMP FUSE

STATUS AND COMM

LED LIGHTS

SW1 SETUP

SWITCHES AND

BLOWER OFF-

DELAY

MODEL PLUG

CONNECTOR

SW2 AIR CONDITIONING

(AC) AIRFLOW SETUP

SWITCHES (6, 7, 8)

COMMUNICATION

CONNECTOR

(WHEN USED)

SW2 CONTINUOUS FAN (CF)

AIRFLOW SETUP SWITCHES (3, 4, 5)

HUMIDIFIER

TERMINAL (24-VAC

0.5 AMP MAX.

ACRDJ – AIR

CONDITIONING

RELAY DISABLE

JUMPER

FLASH

UPGRADE

CONNECTOR

(FACTORY

ONLY)

SOFTWARE

VERSION (V##)

BOARD PART

NUMBER LOCATION

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

Do not bypass the draft safeguard switch, as an unsafe condition could

exist which must be corrected.

Loading...

Loading...