PG80VTLA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

9

INSTALLATION

UPFLOW INSTALLATION

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used. To remove bottom closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom filler

panel. (See Fig. 9).

2. Rotate bottom filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

A10273

Fig. 9 – Removing Bottom Closure Panel

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. This panel MUST be in place when only side return

air is used.

NOTE: Side return-air openings can be used in UPFLOW and most

HORIZONTAL configurations. Do not use side return-air openings in

DOWNFLOW configuration.

DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved for use on

combustible flooring when any one of the following 3 accessories are

used:

• Special Base, KGASB

• Cased Coil Assembly Part No. CNPV, CNRV, CAP, or CAR

• Coil Box Part No. KCAKC

1. Determine application being installed from Table 3.

2. Construct hole in floor. (See Table 3 and Fig. 10).

3. Construct plenum to dimensions specified. (See Table 3 and

Fig. 10).

4. If downflow subbase, KGASB is used, install as shown. (See

Fig. 11). If Coil Assembly Part No. CPVP, CAPMP or CNPVP Coil

Box Part No. KCAKC is used, install as shown. (See Fig. 12).

NOTE: It is recommended that the perforated supply-air duct flanges be

completely folded over or removed from furnace when installing the

furnace on a factory-supplied cased coil or coil box. To remove the

supply-air duct flange, use wide duct pliers or hand seamers to bend

flange back and forth until it breaks off. Be careful of sharp edges.

(Refer to Duct Flanges (Fig. 17) in the “Air Ducts” section.)

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used. To remove bottom closure panel, perform the following:

1. Tilt or raise furnace and remove 2 screws holding bottom filler

panel. (See Fig. 9).

2. Rotate bottom filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws.

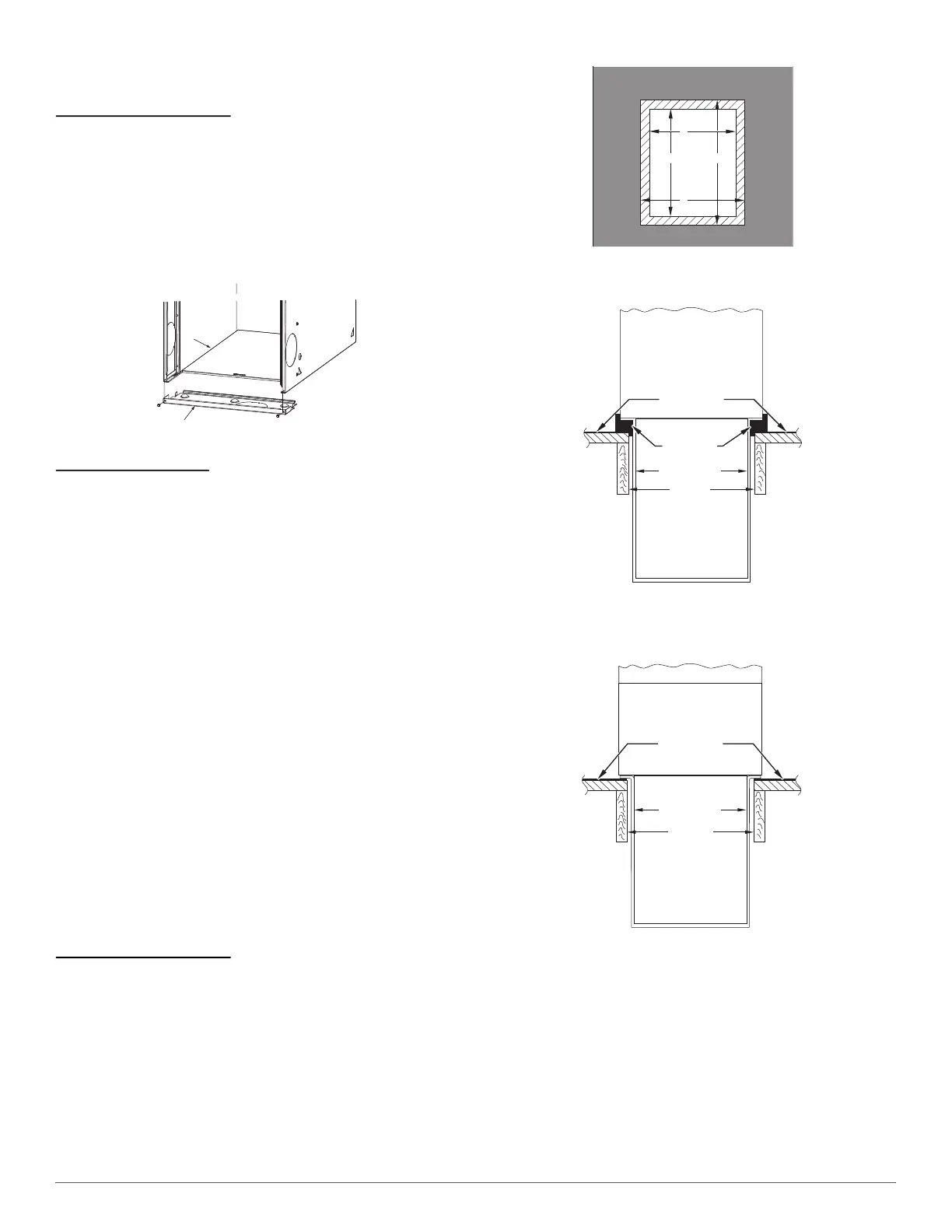

A96283

Fig. 10 – Floor and Plenum Opening Dimensions

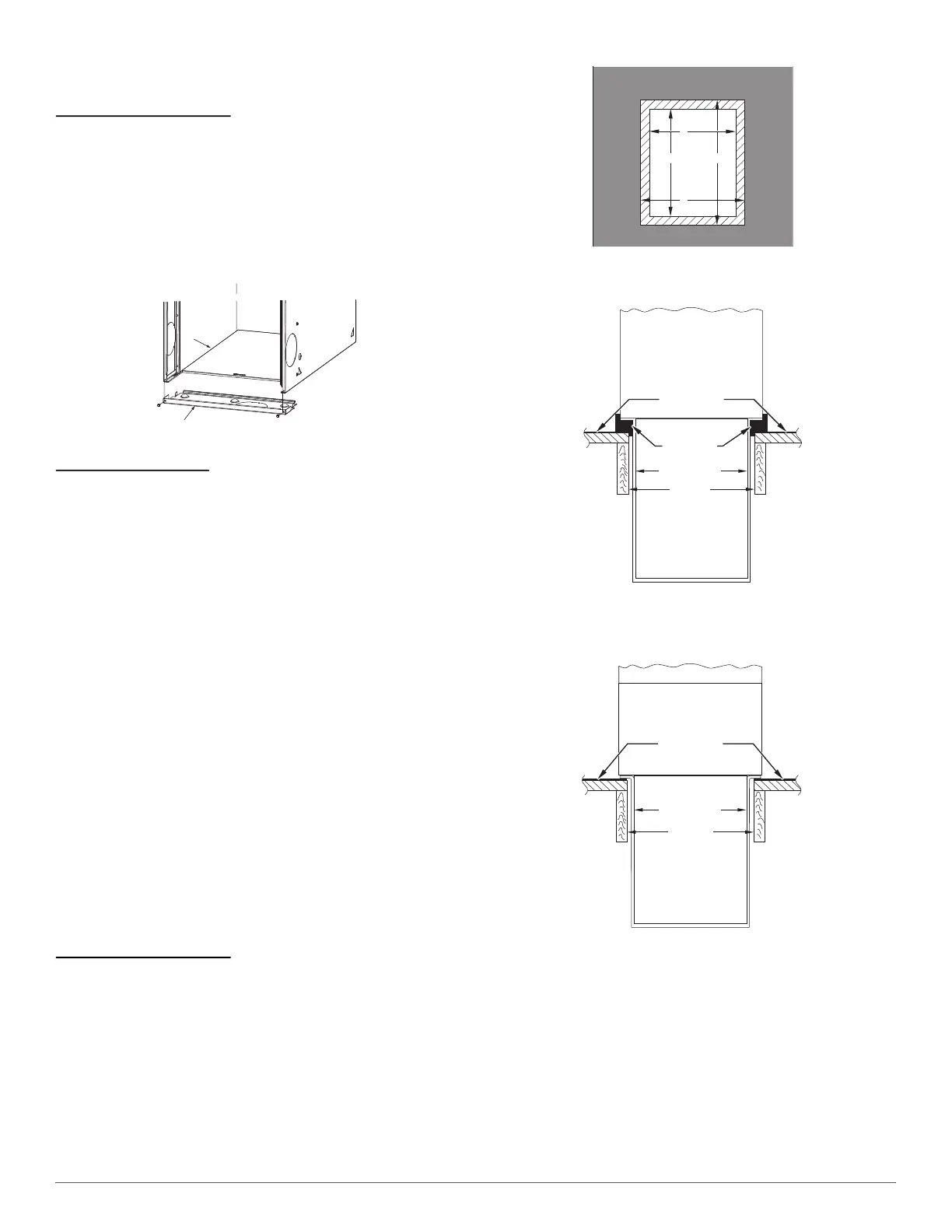

A96285

Fig. 11 – Furnace, Plenum, and Subbase

Installed on a Combustible Floor

A08556

Fig. 12 – Furnace, Plenum, and Coil Assembly or

Coil Box Installed on a Combustible Floor

Bottom

Closure Panel

Bottom Filler Panel

PLENUM

OPENING

C

A

B

D

FLOOR

OPENING

DOWNFLOW

SUBBASE

SHEET METAL

PLENUM

FLOOR

OPENING

FURNACE

(OR COIL CASING

WHEN USED)

COMBUSTIBLE

FLOORING

APPROVED

COIL ASSEMBLY

OR

COIL BOX

FURNACE

SHEET METAL

PLENUM

FLOOR

OPENING

COMBUSTIBLE

FLOORING

Loading...

Loading...