FB, FE, FF1E, FFM, FG, FH, FJ, FMA, FT, FV, FX, FY, FZ, F54, PF: Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

14

How to Troubleshoot

RAT/SAT Functionality

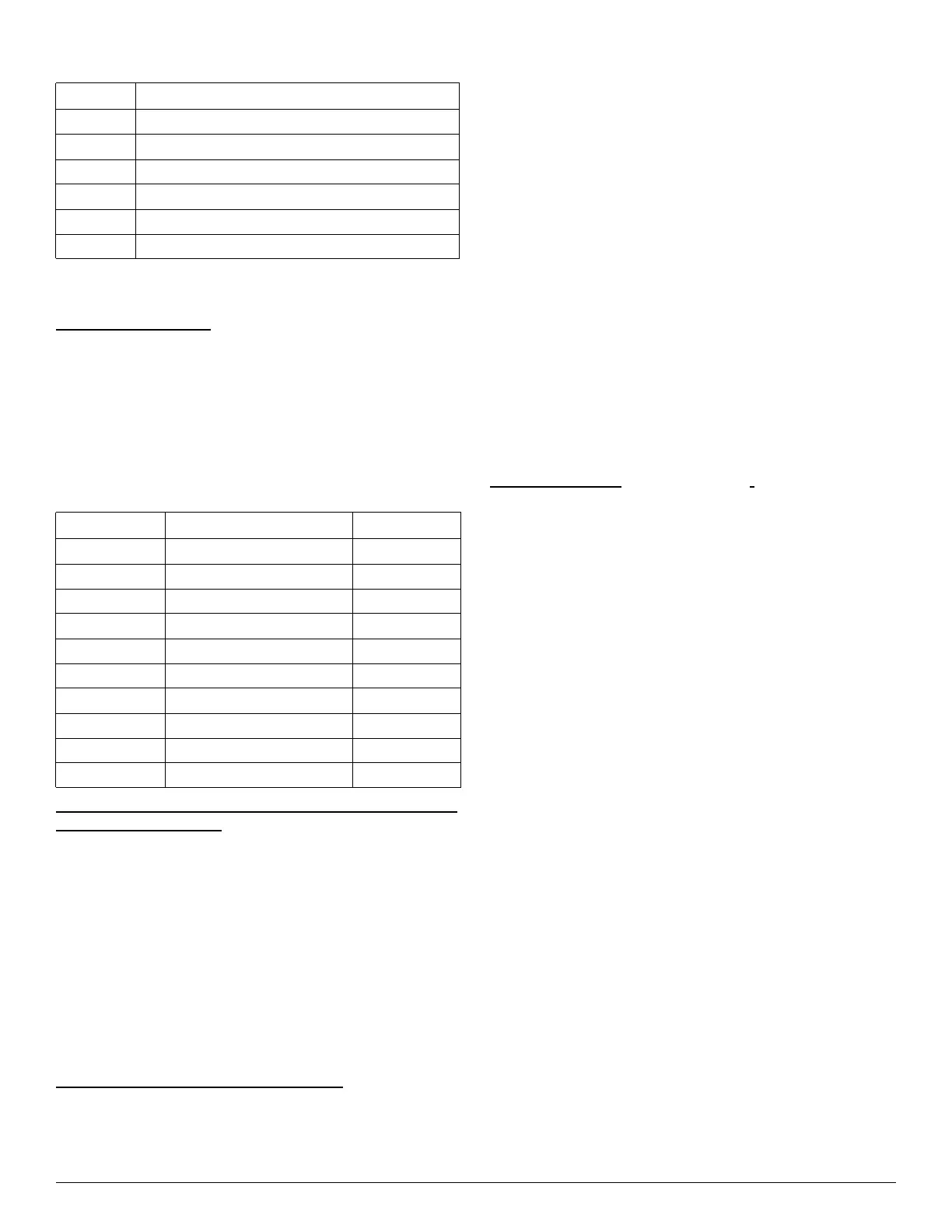

One method of determining RAT/SAT functionality is to compare the

actual resistance of the sensor with the nominal resistance at sample

temperatures. The table below indicates several example values in the

operating range of the sensors.

Communication Loss and Board Fault

Refer to thermostat advanced installation and configuration instructions

found at carrier.hvacpartners.com/InteliSense.

How Does the Service Tech Know when the System is

Functioning Properly?

InteliSense is fully functioning when communication is established

(indicated by LED or through the thermostat) and the thermostat has

successfully fully learned all of the equipment and data is being

displayed on the Connected Portal/service tech app.

FE, FT

Model FE and FT fan coil is designed to be installed with a

communicating user interface. The FE and FT fan coil will provide

airflow at a rate commanded by the User Interface. The nominal

airflow/ton rate is 350 CFM/ton. The User Interface will modify the

commanded airflow under certain operating modes. Refer to the User

Interface literature for further system control details. This fan coil will

not respond to commands from a common thermostat except under

certain emergency situations explained in this document.

Electronically Commutated Motor ECM

An ECM motor is fed high voltage AC power through the 5-pin

connector. The AC power is then internally rectified to DC by a diode

module. After rectification, DC signal is electronically communicated

and fed in sequential order to 3 stator windings. The frequency of these

communication pulses determines motor speed. The rotor is permanently

magnetized.

ECM Control Power

The ECM control power is supplied from R circuit through printed

circuit runs to motor control connector Plug 1, Pin 1, through motor

control harness to motor. The C side of low-voltage control power circuit

is connected by printed circuit runs to motor connector Plug 1, Pin 2 then

through motor control harness to motor. A digital signal is sent from

Plug 1, Pins 3 and 4 to communicate with the motor including all airflow

requirements.

Low-Voltage Circuit Fusing and Reference

The low-voltage circuit is fused by a board-mounted 5A automotive type

fuse placed in series with transformer SEC2 and R circuit. The C circuit

of transformer is referenced to chassis ground through a printed circuit

run at SEC1 connected to metal standoff.

NOTE: The PCB must be mounted with two screws and motor ground

lead secured to blower housing or erratic motor operation can result.

Transformer, Motor, and Electric Heater Power Connection

Transformer high voltage supplied from electric heater package or high

voltage leads through 12-pin heater connector plug/recp2. The ECM 3.0

power connections are made at the transformer primary terminals. The

transformer secondary connections are made at SEC1 and SEC2

connectors.

Troubleshooting (FE4/FE5A/FE5B)

NOTE: Always check high and low voltage supply to the fan coil

components. Check the integrity of the plug receptacle connections and

fan coil wiring harness prior to assuming a component failure.

LED Description

LEDs built into fan coil control provide installer or service person

information concerning operation and/or fault condition of the fan coil

control and ECM motor. This information is also available at system

User Interface in text with basic troubleshooting instructions. Careful

use of information displayed will reduce the need for extensive manual

troubleshooting.

The amber LED located at bottom center of control adjacent to motor

harness plug is Motor Status LED, and it is labeled MOTOR. A second

amber LED, located in upper right center of control adjacent to System

Communications connector (A,B,C,D) is the System Status LED, and it

is labeled STATUS. The green LED labeled COMM is also located

adjacent to System Communications connector, below STATUS LED,

and is used as an indicator of system communications status. Status

Codes will be displayed on the STATUS LED using the following

protocol:

1. The number of short flashes indicates first digit of code.

2. The number of long flashes indicates second digit of code.

3. A short flash is 0.25 seconds on. A long flash is one second on.

4. The time between flashes is 0.25 seconds.

5. The time between last short flash and first long flash is 1 second.

6. The LED will be off for 2.5 seconds before repeating code.

Fan Coil Control Start-Up and System Communications

Troubleshooting

On power up, green COMM LED will be turned off until successful

system communications are established (this should happen within 10

seconds). Once communications with User Interface are successful,

COMM LED will be lit and held on. At the same time, amber STATUS

LED will be lit and held continuously on until a request for operating

mode is received. The STATUS LED will be on any time fan coil is in

idle mode.

If, at any time, communications are not successful for a period exceeding

two minutes, fan coil control will only allow emergency heating or

cooling operation using a common thermostat, a non-communicating

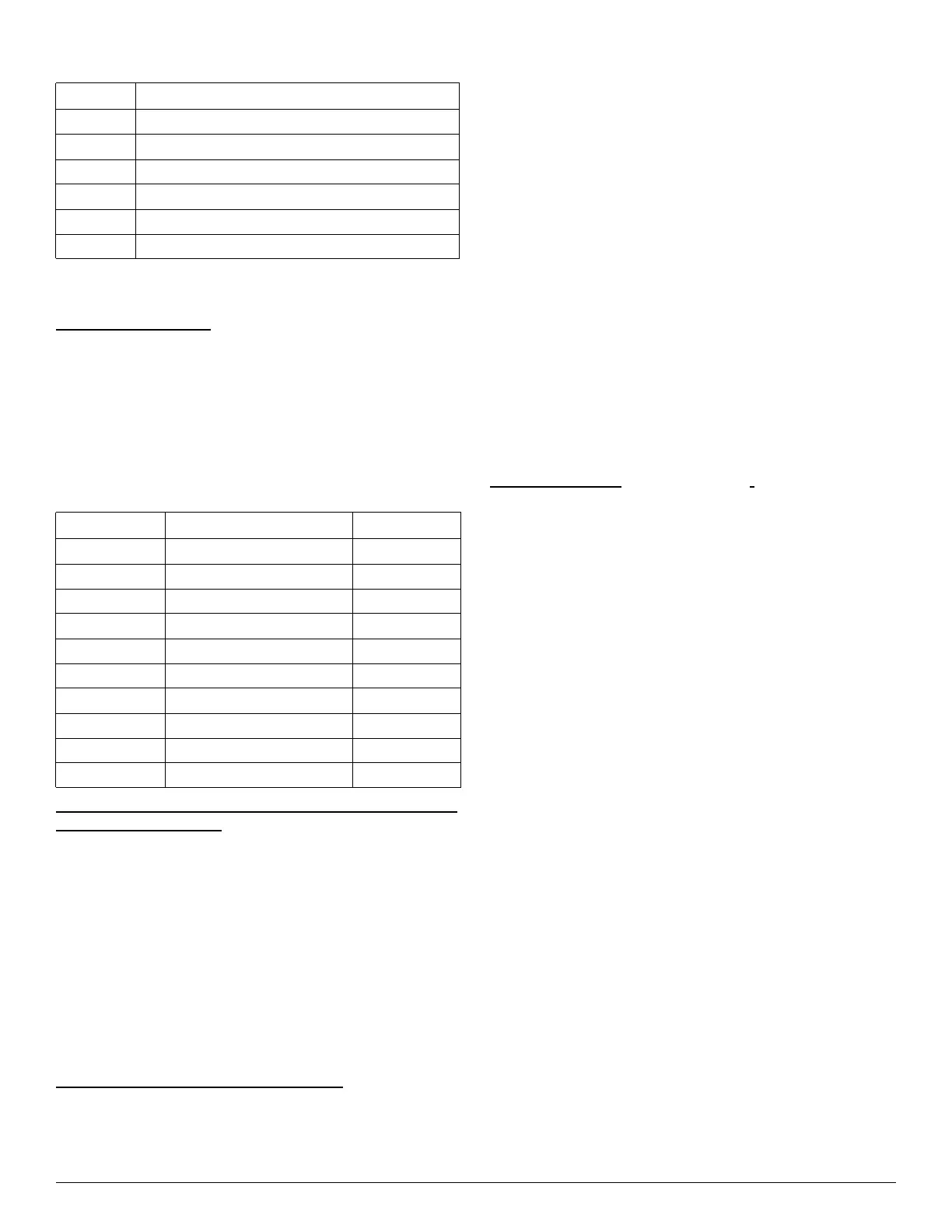

Table 7 – Diagnostic Code List

*

*. Refer to the Service Tech App or Connected Portal for more information.

Timestamps shall be applied to the fault when it occurs. Fault codes can be

read through the dealer portal or through the service tech app.

Code Description

30.1 InteliSense Communication Loss

30.2 InteliSense Communication Board Fault

52.1 Supply Air Temperature Open Fault

52.2 Supply Air Temperature Short Fault

53.1 Return Air Temperature Open Fault

53.2 Return Air Temperature Short Fault

Table 8 – RAT/SAT Sensor Values

Temperature (°F) Nominal Resistance (K-ohms) Tolerance (± %)

23 42.6 5.92

32 32.8 2.85

41 25.5 2.76

50 19.9 2.68

59 15.7 2.59

68 12.5 2.51

77 10.0 2.44

86 8.1 2.37

95 6.5 2.30

104 5.3 4.48

Loading...

Loading...